Control method and device for applying back pressure to annulus

An annulus and target position technology, applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of oil and gas wells such as lost circulation, high pressure, and large back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

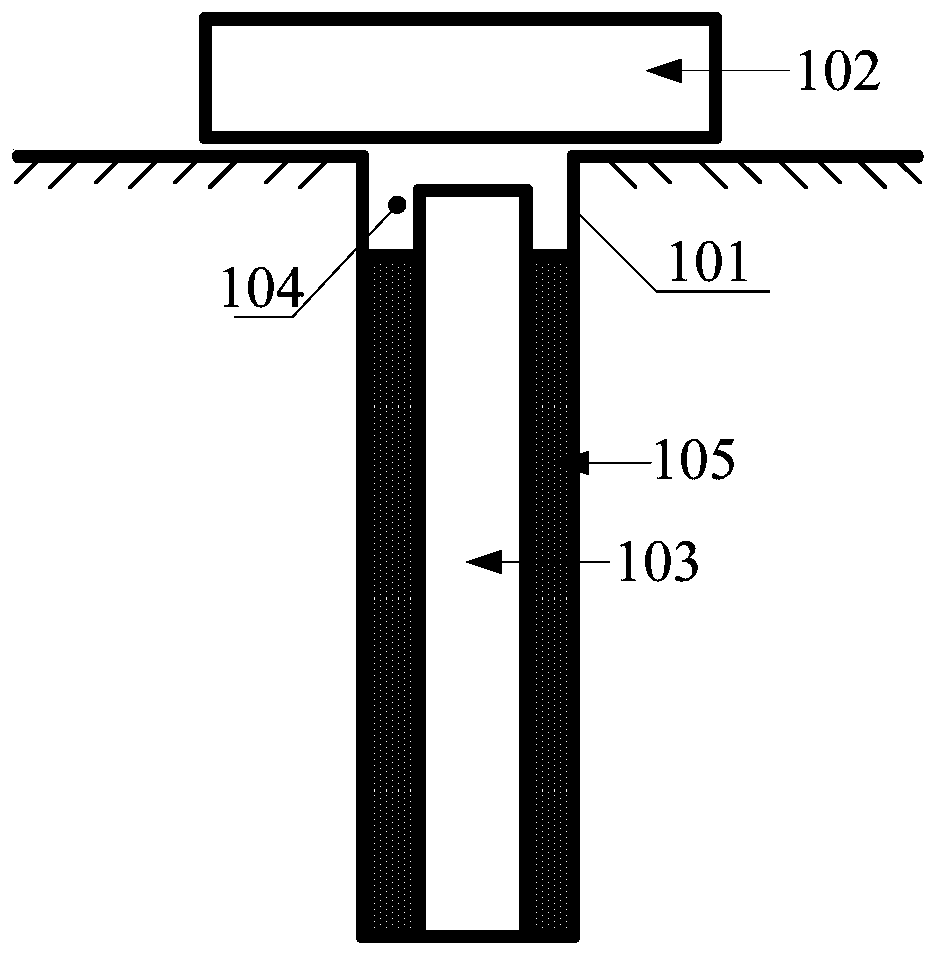

[0052] Please refer to figure 1 , figure 1 It is a schematic diagram of the implementation environment of the control method for applying back pressure to the annular space provided by the embodiment of the present invention. The implementation environment includes: an oil and gas well 101 and a pressure control device 102 located at the wellhead of the oil and gas well 101 . When the oil and gas well 101 needs to be cemented, the casing 103 can be run in the oil and gas well 101 and the cement slurry 105 can be injected into the annular space 104 between the oil and gas well 101 and the casing 102 . During the waiting period of the cement slurry 105, the cement slurry 105 will experience weightlessness and induce air channeling. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com