Method for producing multilayer fiber composite preform for fiber composite component

一种纤维复合、多层纤维的技术,应用在纺织品和造纸、编织物等方向,能够解决废品、妨碍纤维复合构件几何和机械性能以及光学外观等问题,达到简单措施、制造改善、低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Components with the same function and mode of action are in the Figures 1 to 3 Correspondingly provided with the same reference numerals.

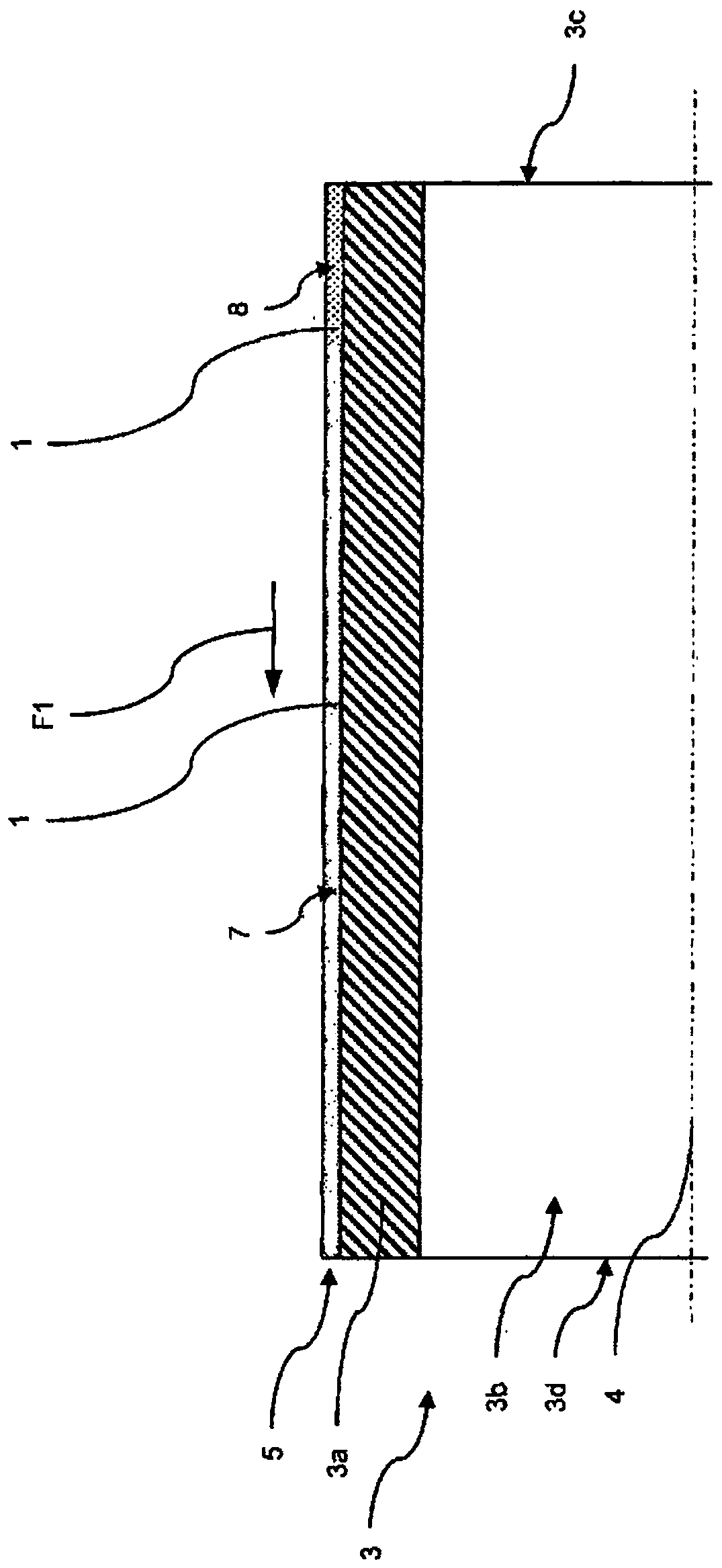

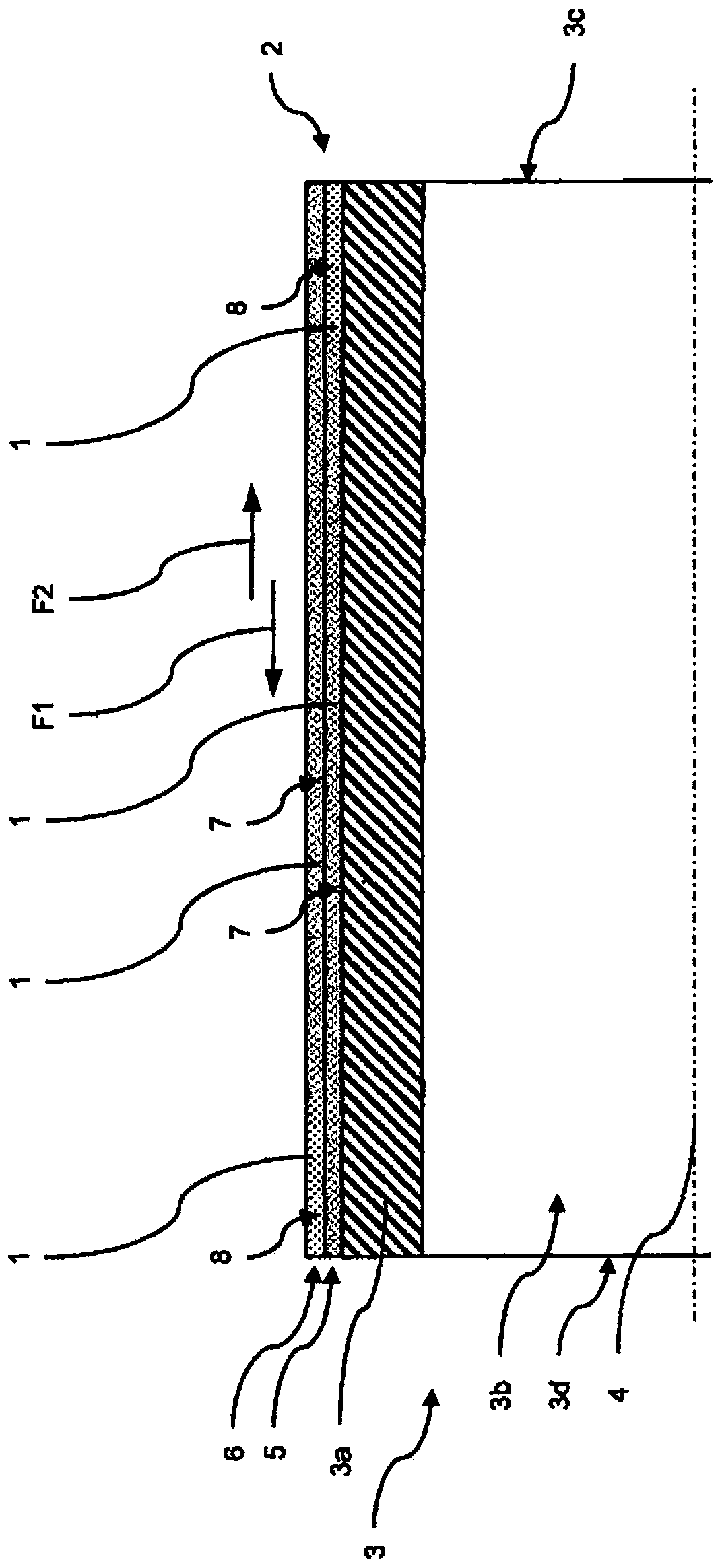

[0035] figure 1 A section of the support core 3 covered with the first textile layer 5 is schematically shown in a side view. The support core 3 is designed rotationally symmetrically about the support core longitudinal axis 4 and has a surrounding support core wall 3 a which radially surrounds the support core cavity 3 b. On the outer side of the support core 3 facing away from the support core longitudinal axis 4 , or on the support core wall 3 a, a first fabric layer 5 made of fiber rovings 5 is arranged. By means of the method according to the invention, said first fabric layer 5 is produced from a first support core end 3c in a first weaving direction F1 towards a second support core end 3d.

[0036] The first textile layer 5 has a region of low textile density 8 on the first support core end 3c and a region of high texti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com