Special trolley electromagnetic gripper for splicing corrugated plates

A technology of corrugated boards and trolleys, which is applied in shaft equipment, shaft lining, mining equipment, etc., to achieve accurate, fast and high-quality assembly, improve the level of construction mechanization, and ensure the safety of workers and the quality of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the embodiments and accompanying drawings.

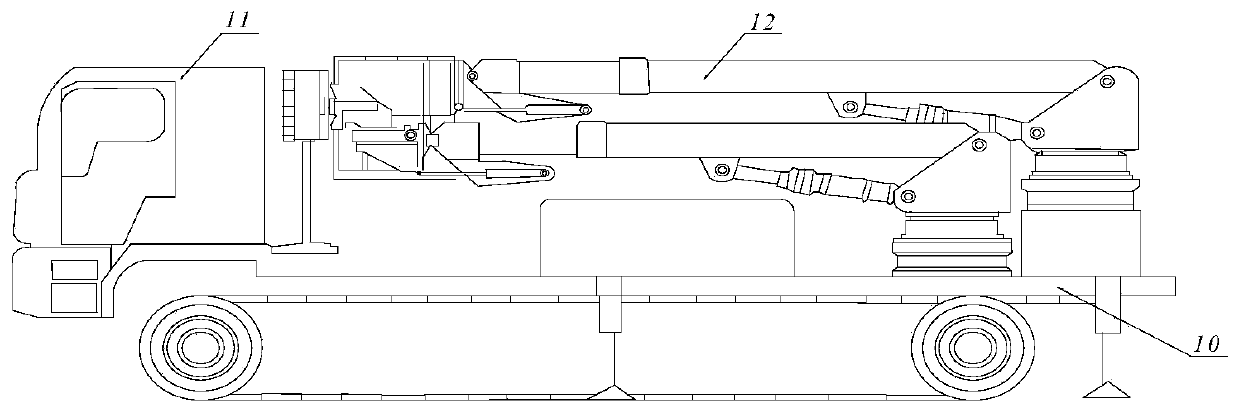

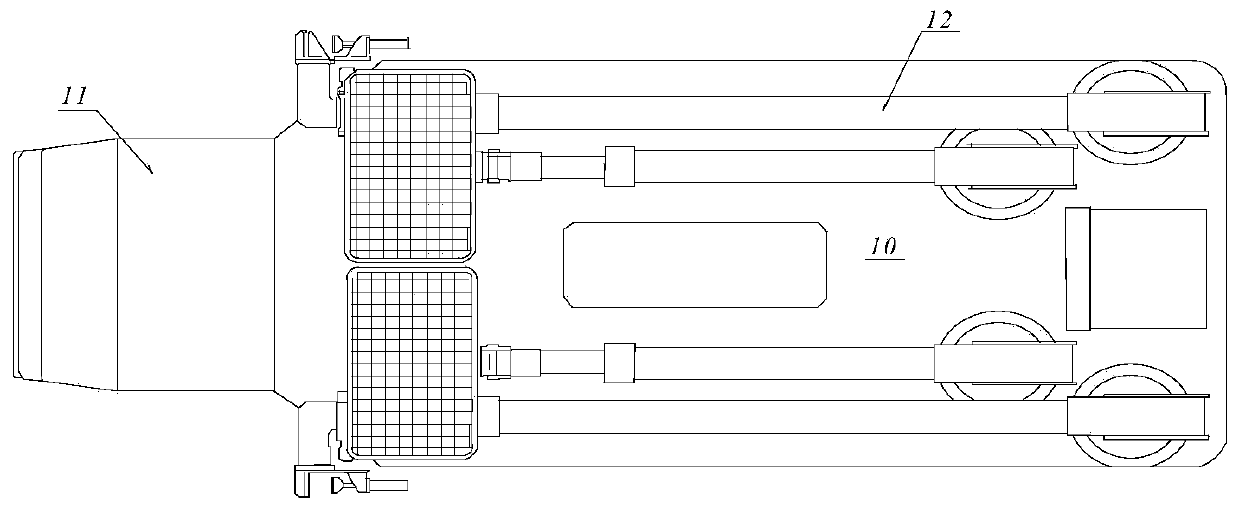

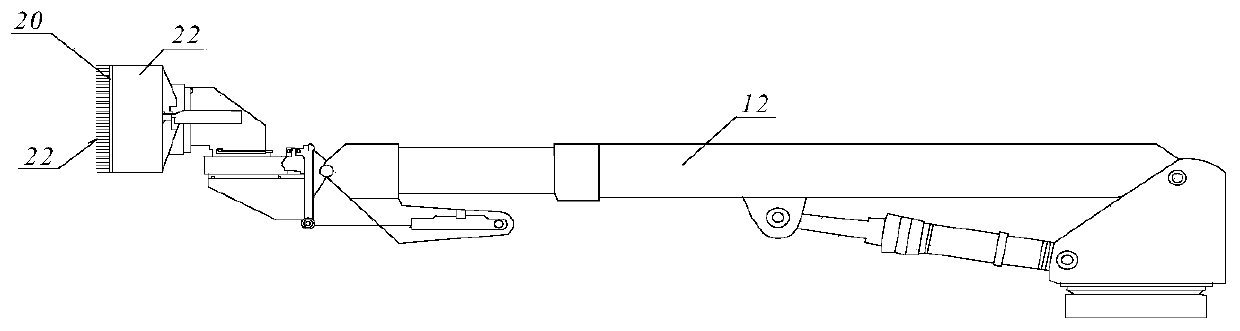

[0022] refer to Figure 1 to Figure 7 , The present invention is a special trolley electromagnetic gripper for corrugated board assembly, the electromagnetic gripper is fixedly installed on the front end of the trolley mechanical arm 12, and the rear end of the trolley mechanical arm 12 is hinged with the trolley base 10 through joints. The electromagnetic gripper includes an electromagnetic chuck 20 and an electromagnetic device 23. The electromagnetic chuck 20 is fixedly installed on the front port of the bottom case 21, the electromagnetic device 23 is fixedly installed in the bottom case 21, and the rear end of the bottom case 21 is connected to the trolley mechanical arm 12. Hinges are formed by joints. The electromagnetic chuck 20 is composed of telescopic electromagnetic heads 22 evenly spaced in its annular plane, and each telescopic electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com