Construction method of open-cut prefabricated underground structure

A prefabricated assembly and underground structure technology, applied in underwater structures, infrastructure projects, artificial islands, etc., can solve the problems of small structure space, difficult to meet the requirements of large-scale underground projects and other functions, to reduce construction investment, The effect of shortening construction period and reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

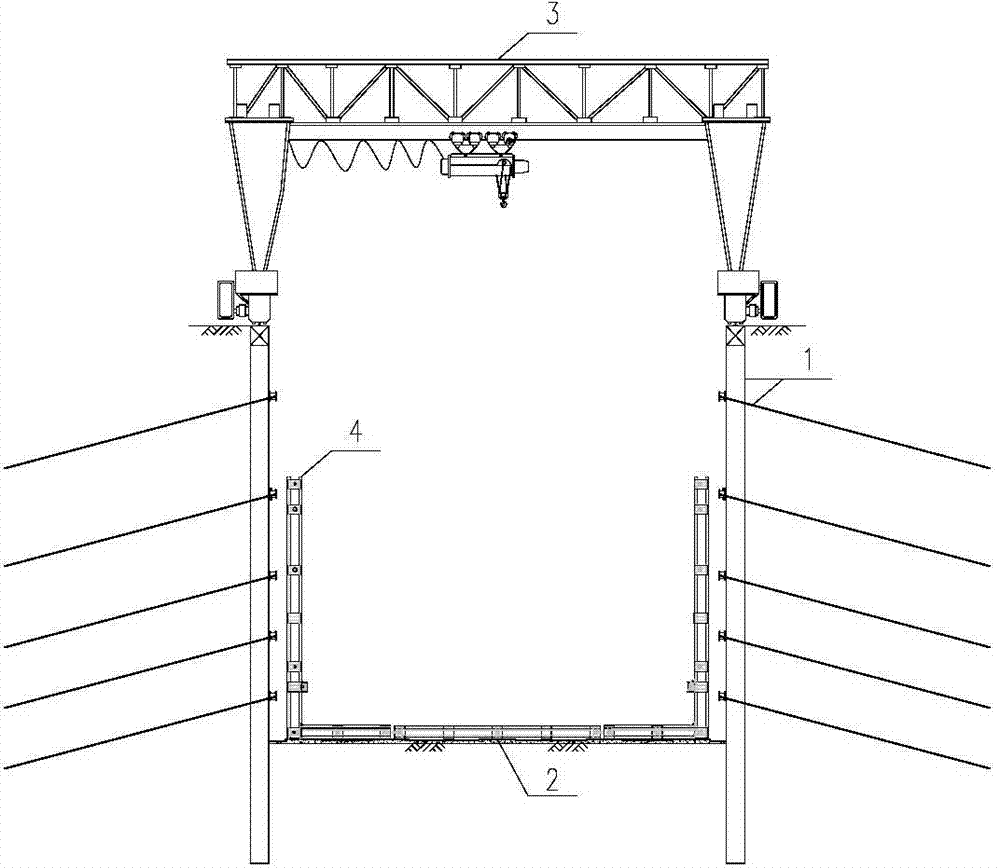

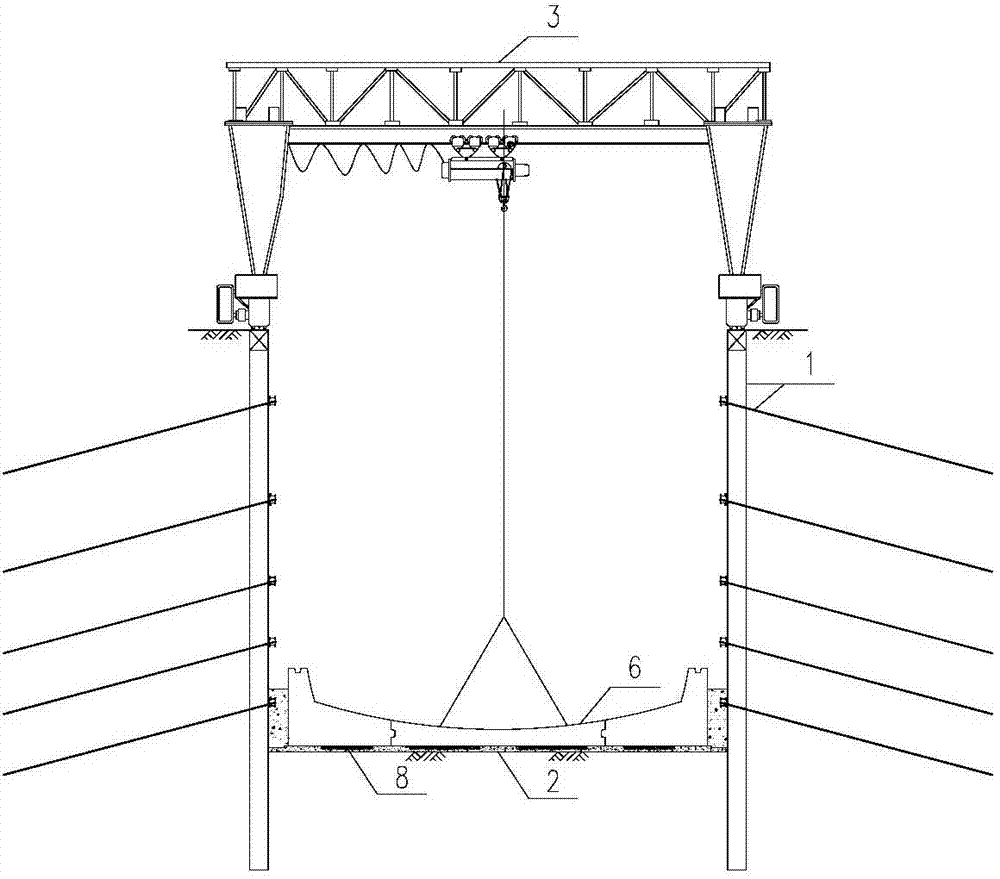

[0046] see Figure 1 to Figure 8 Shown: take the pile+anchor rod foundation pit structure as an example to explain the specific embodiment of the present invention as follows:

[0047] (1) Level the site, construct the foundation pit support structure 1, excavate to the design elevation of the pit bottom, construct the base cushion 2, and install and debug the gantry crane 3 in place;

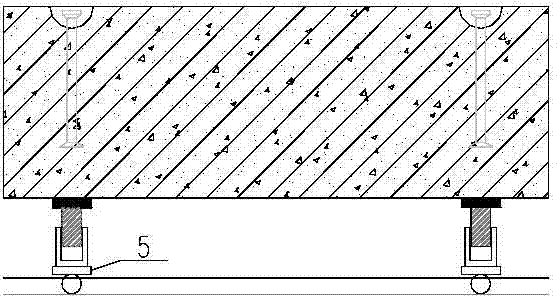

[0048] (2) Precisely place the points through the theodolite or the total station, and manually set out the lines on the base cushion layer or set out the lines with a laser instrument to ensure that the prefabricated component base plate 6 is accurately in place;

[0049] (3) Install the fixing bracket 4 on the starting end face of the assembly in advance to ensure that the prefabricated components of the first ring are accurately positioned and locked;

[0050] (4) Accurate positioning of the prefabricated component bottom plate 6 is achieved through the gantry crane 3 or the base translatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com