Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc. problems, to maintain driving stability, improve snow performance, and improve snow removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

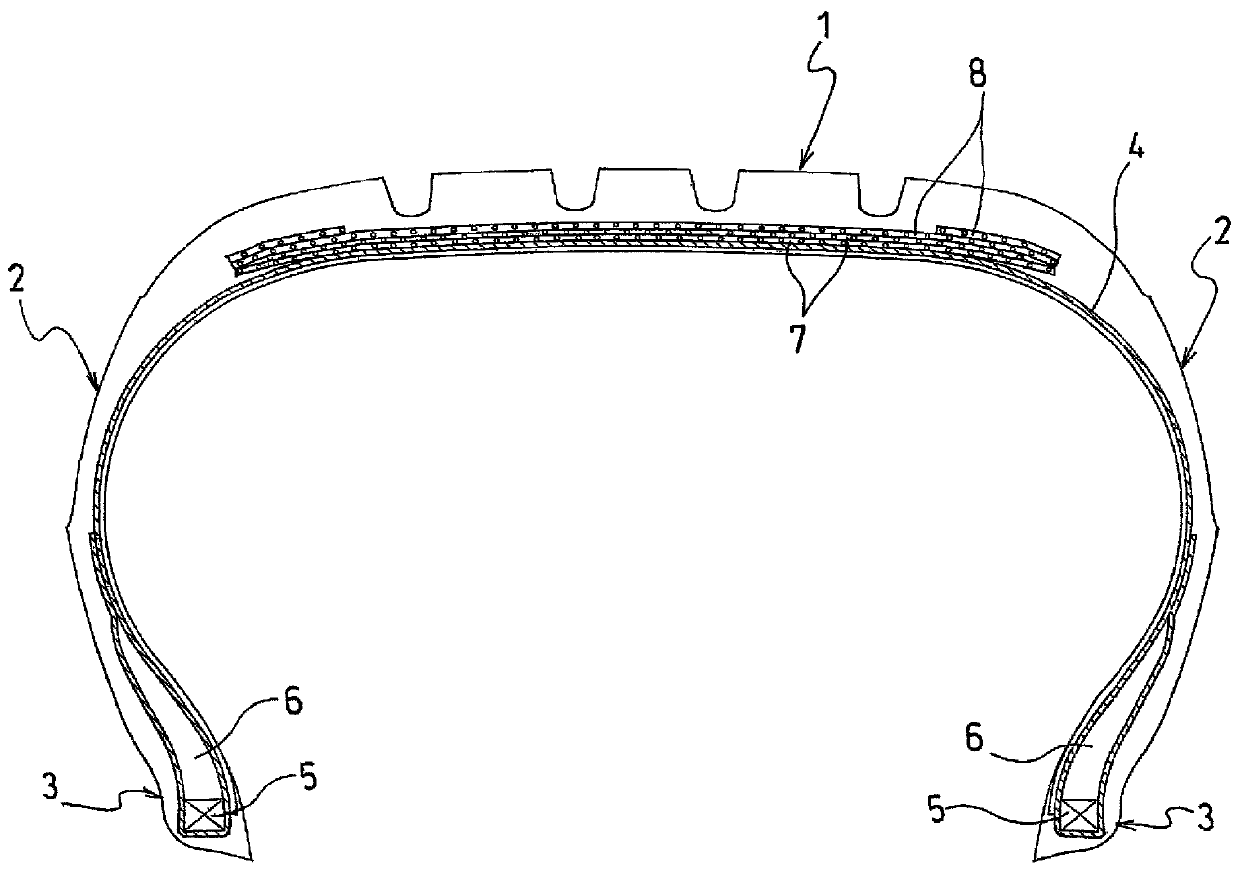

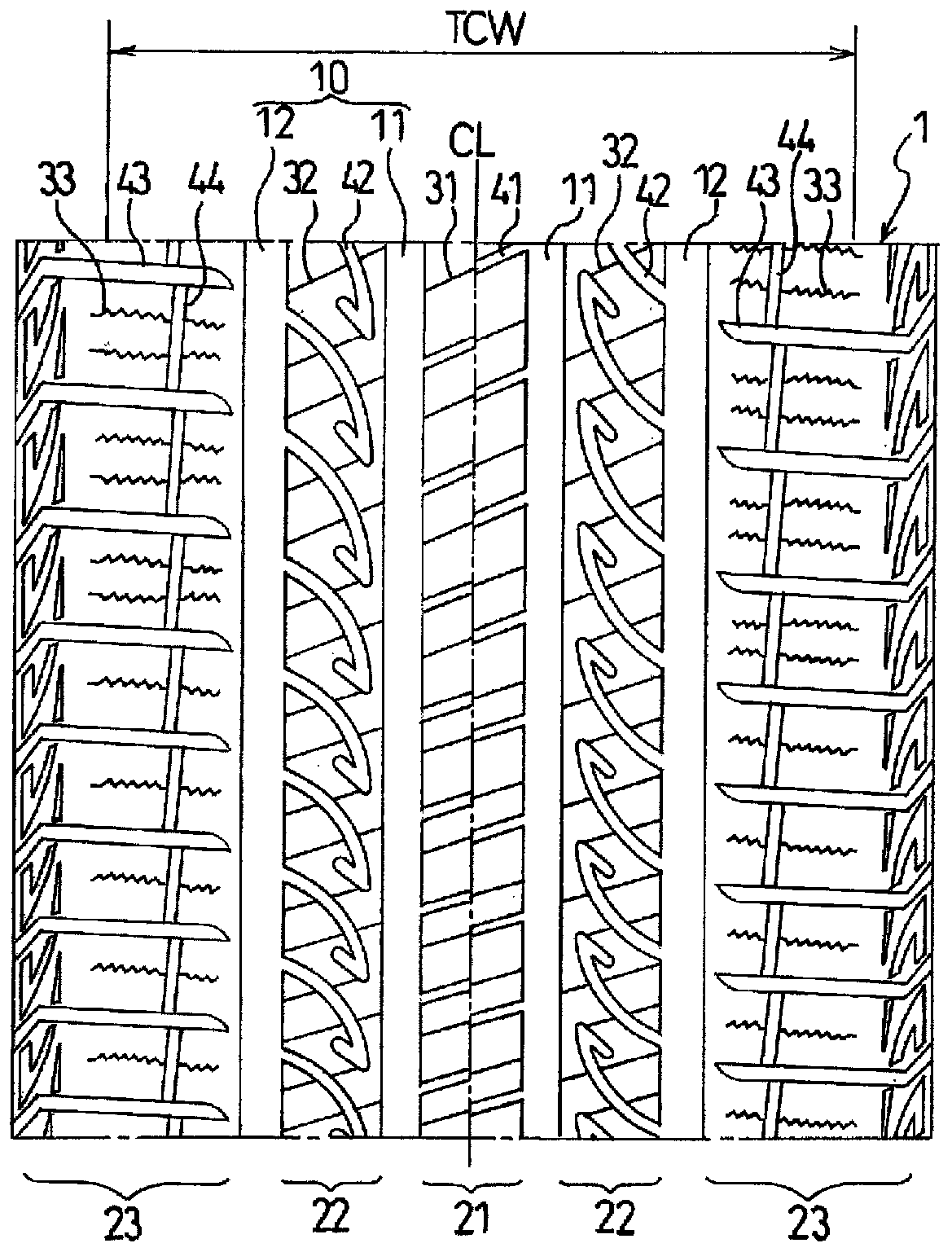

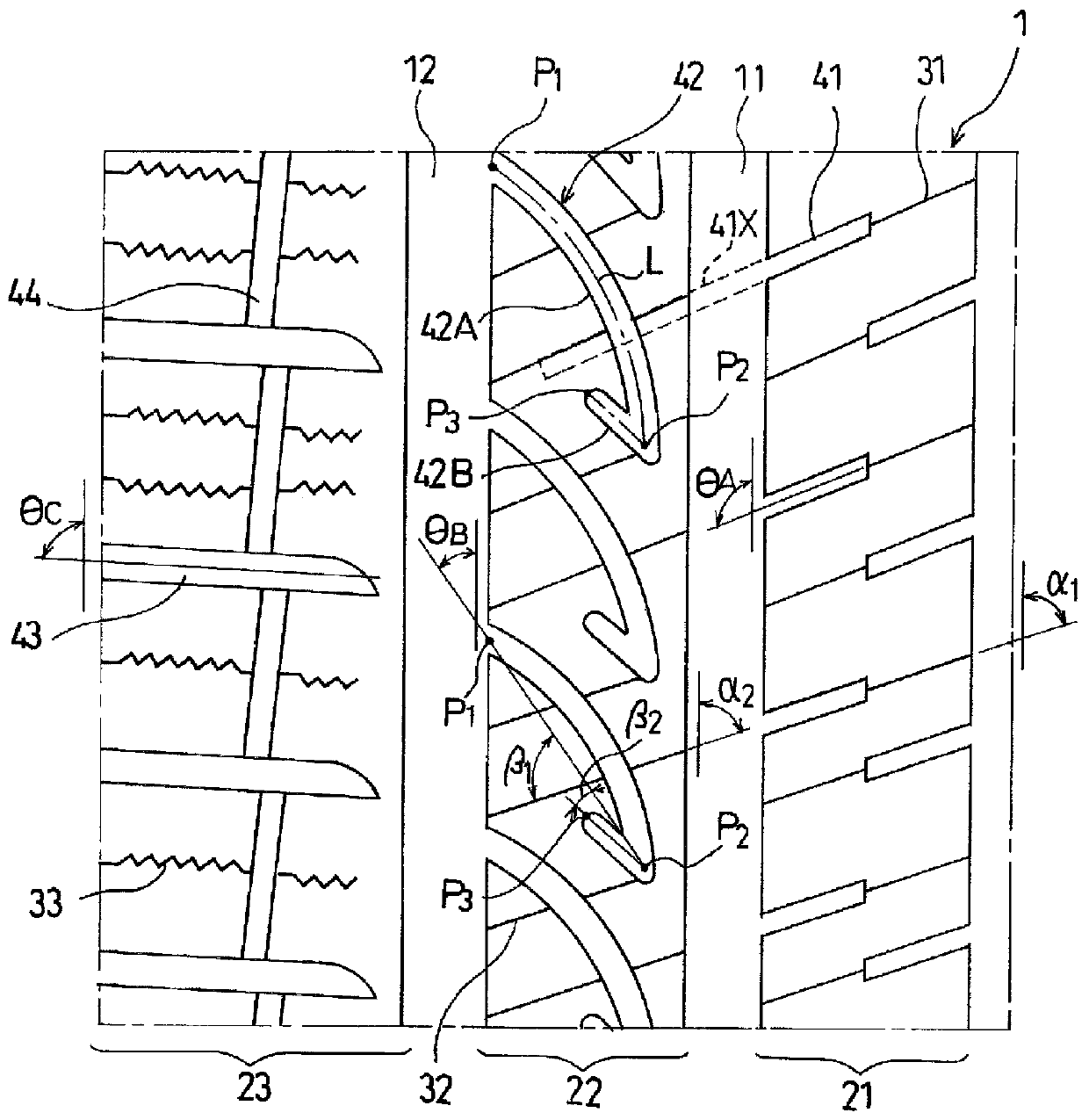

[0044] The tires of Examples 1 to 5 were produced, the tire size was 205 / 55R16 91V, and the pneumatic tire was provided with: a tread portion extending in the tire circumferential direction in an annular shape; a pair of sidewall portions disposed on both sides of the tread portion ; and a pair of bead portions disposed on the inner side in the tire radial direction of these sidewall portions, such as figure 2 As shown, a pair of first main grooves and a pair of second main grooves extending in the tire circumferential direction are formed on the tread portion, and a first land portion is defined between the pair of first main grooves. A second land portion is defined between the groove and the second main groove, and a third land portion is defined outside the second main groove. On the first land portion, a plurality of first patterns (groove width) extending in the tire width direction are formed. : 1.0mm) and a plurality of transverse grooves (groove width: 1.5mm) extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com