Sewage treatment fisher

A technology of sewage treatment and salvage, which is applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc. It can solve the problems of debris falling out, troublesome operation, unclean sewage treatment, etc., and achieve sewage treatment clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

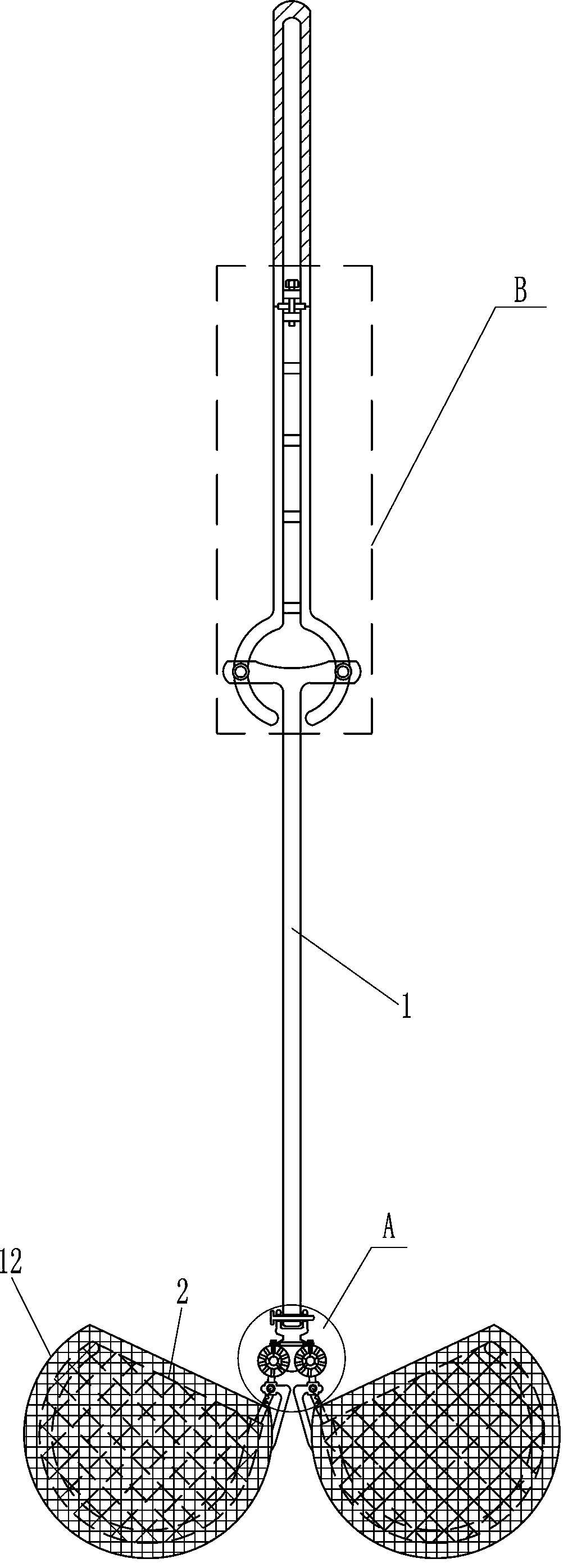

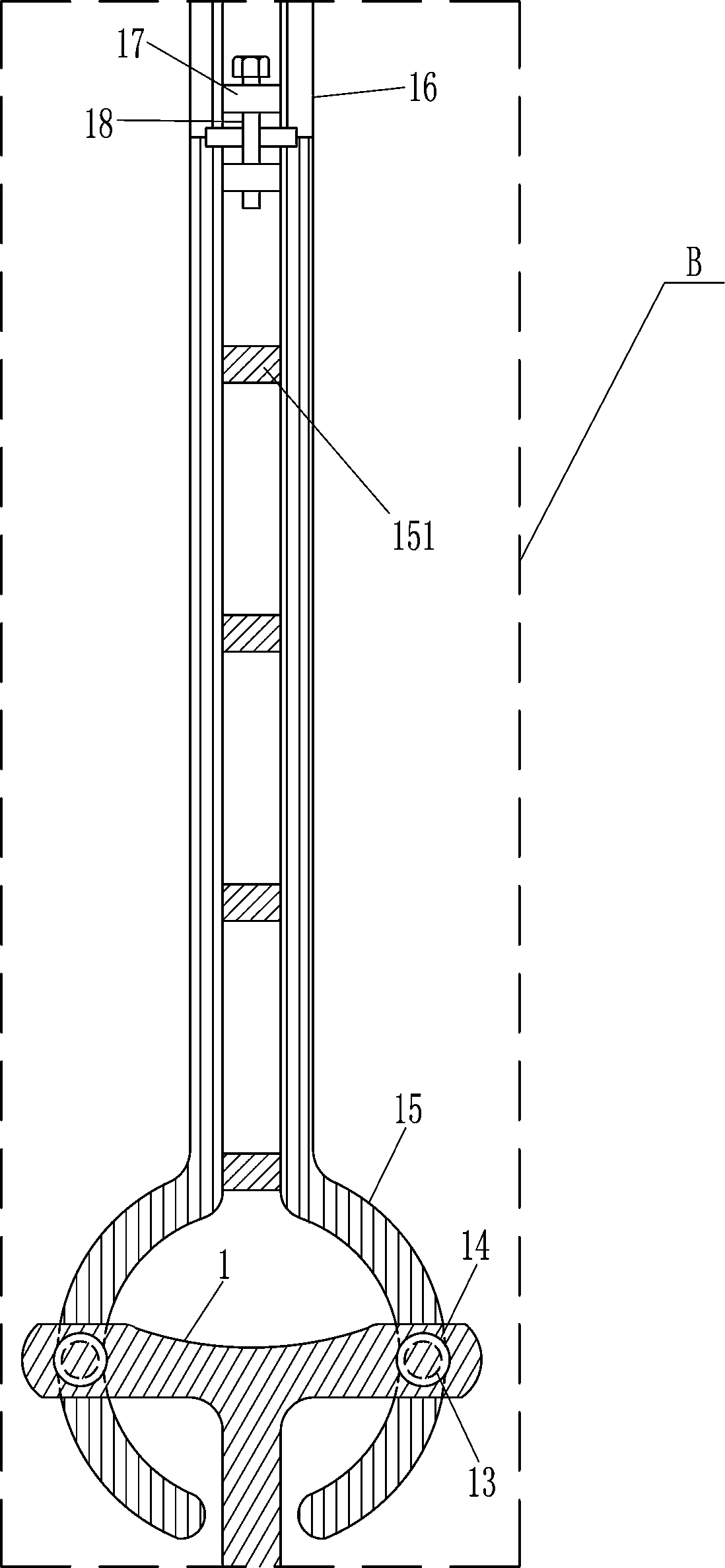

[0016] A sewage treatment overshot, such as Figure 1-2 As shown, it includes a pillar 1, a first screen frame 2, a mounting pillar 3, a first screw rod 5 and an adjustment mechanism 6, and a mounting pillar 3 is arranged below the pillar 1, and the left and right sides of the mounting pillar 3 have first threaded holes 4, The first threaded hole 4 is provided with a first screw 5, the first screw 5 passes through the pillar 1, the mounting column 3 and the pillar 1 are connected by the first screw 5, the bottom of the mounting column 3 is provided with an adjustment mechanism 6, and the adjustment mechanism 6 The first screen frame 2 is arranged on the left and right sides.

Embodiment 2

[0018] A sewage treatment overshot, such as Figure 1-2 As shown, it includes a pillar 1, a first screen frame 2, a mounting pillar 3, a first screw rod 5 and an adjustment mechanism 6, and a mounting pillar 3 is arranged below the pillar 1, and the left and right sides of the mounting pillar 3 have first threaded holes 4, The first threaded hole 4 is provided with a first screw 5, the first screw 5 passes through the pillar 1, the mounting column 3 and the pillar 1 are connected by the first screw 5, the bottom of the mounting column 3 is provided with an adjustment mechanism 6, and the adjustment mechanism 6 The first screen frame 2 is arranged on the left and right sides.

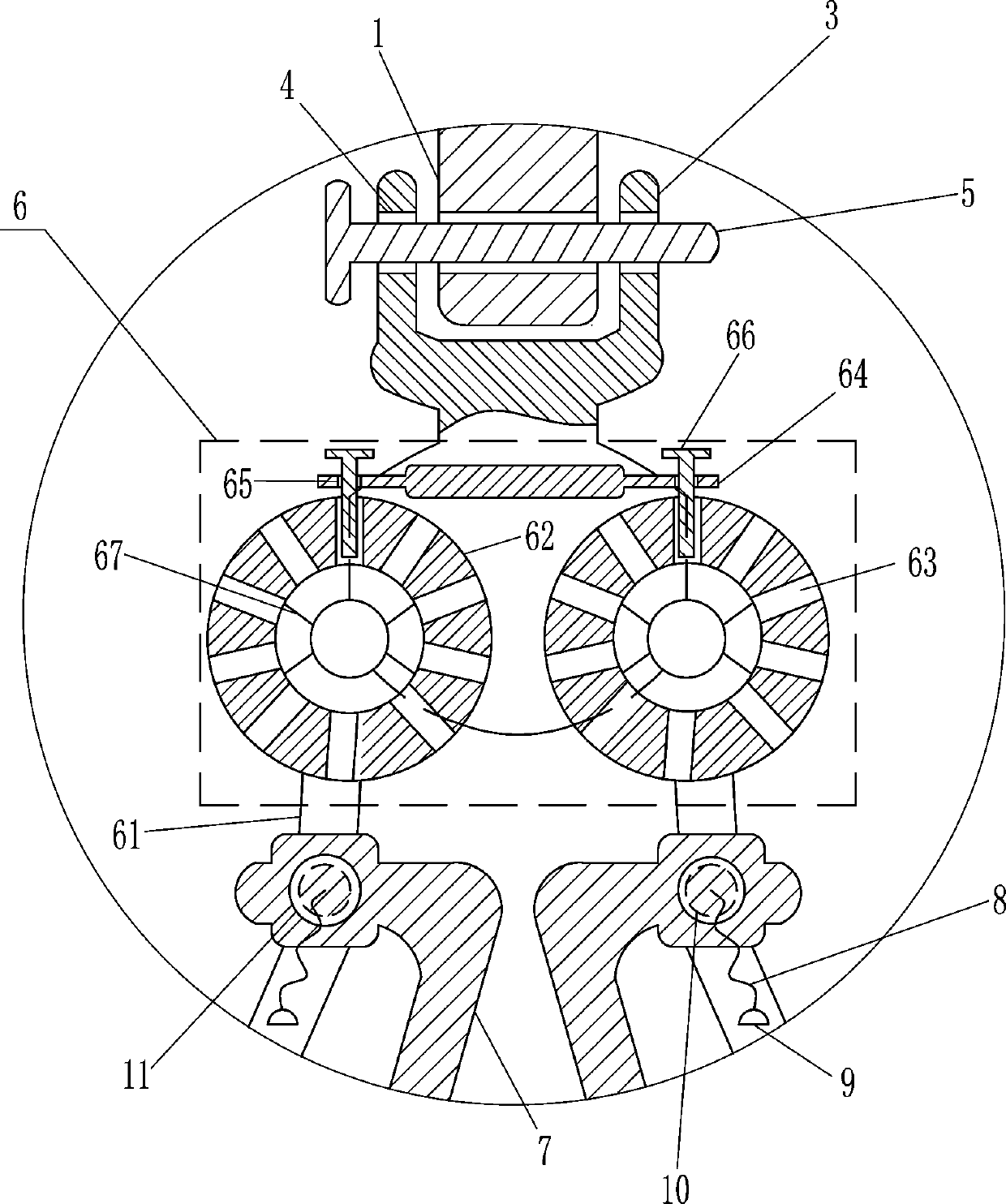

[0019] The adjustment mechanism 6 includes a swing bar 61, an annular block 62, a fixed rod 64, a first bolt 66 and a first connecting block 67. The front side of the mounting column 3 is provided with a fixed rod 64, and the mounting column 3 is connected to the fixed rod by welding. 64 connection, the...

Embodiment 3

[0021] A sewage treatment overshot, such as Figure 1-2 As shown, it includes a pillar 1, a first screen frame 2, a mounting pillar 3, a first screw rod 5 and an adjustment mechanism 6, and a mounting pillar 3 is arranged below the pillar 1, and the left and right sides of the mounting pillar 3 have first threaded holes 4, The first threaded hole 4 is provided with a first screw 5, the first screw 5 passes through the pillar 1, the mounting column 3 and the pillar 1 are connected by the first screw 5, the bottom of the mounting column 3 is provided with an adjustment mechanism 6, and the adjustment mechanism 6 The first screen frame 2 is arranged on the left and right sides.

[0022] The adjustment mechanism 6 includes a swing bar 61, an annular block 62, a fixed rod 64, a first bolt 66 and a first connecting block 67. The front side of the mounting column 3 is provided with a fixed rod 64, and the left and right sides of the fixed rod 64 are provided with second Threaded hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com