Fender front mounting bracket

A technology for installing brackets, fenders, applied in the direction of transportation and packaging, upper structure, bumper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

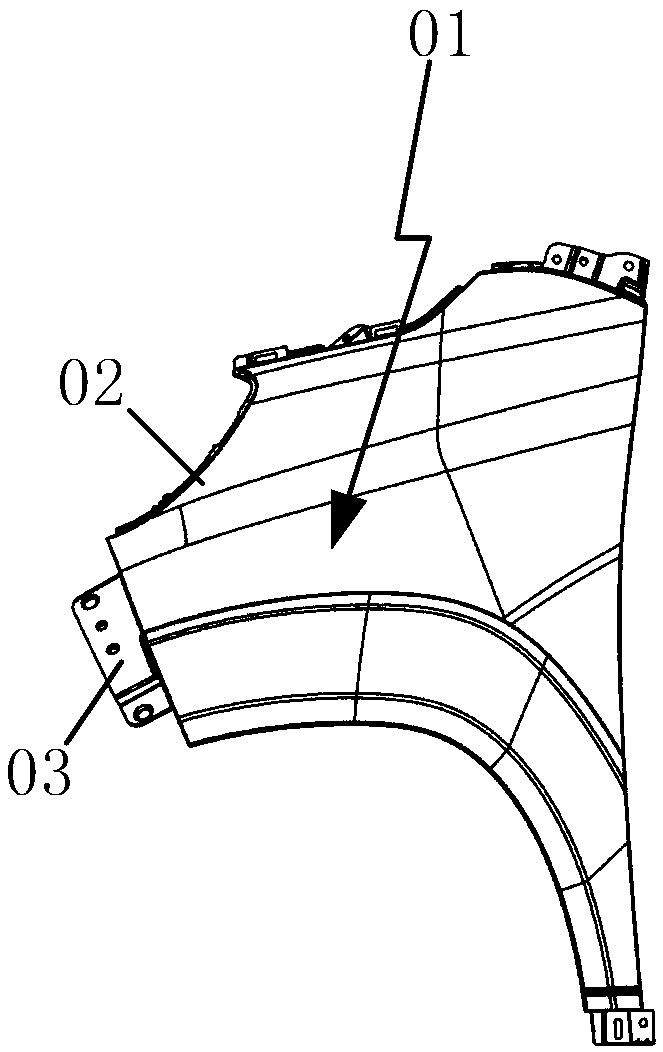

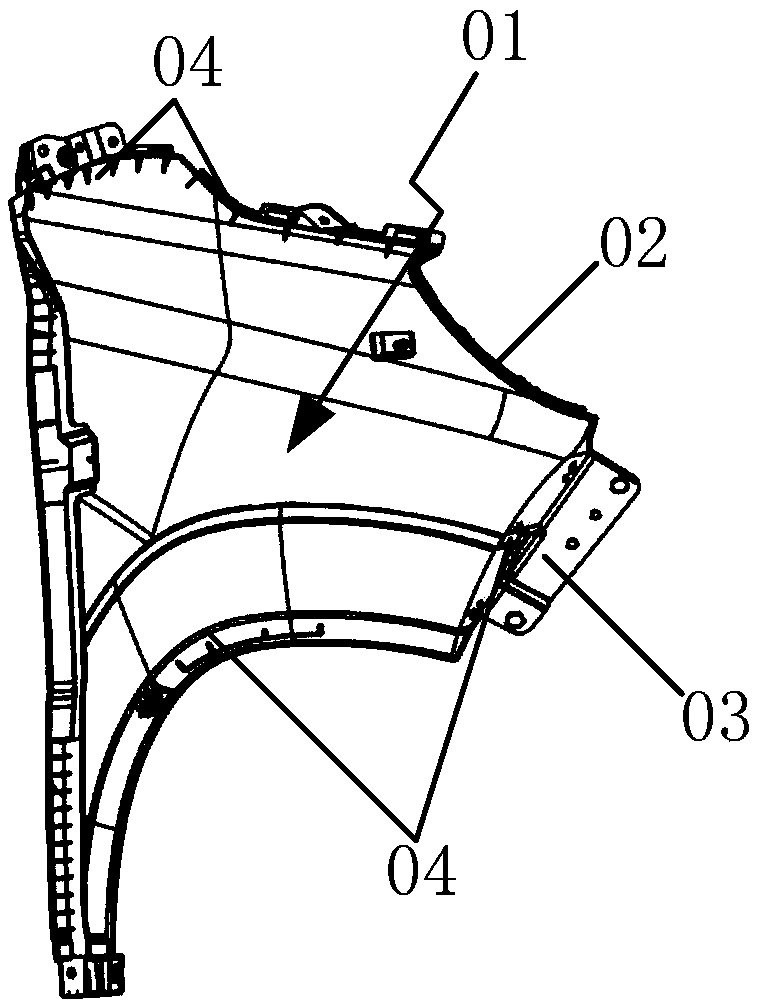

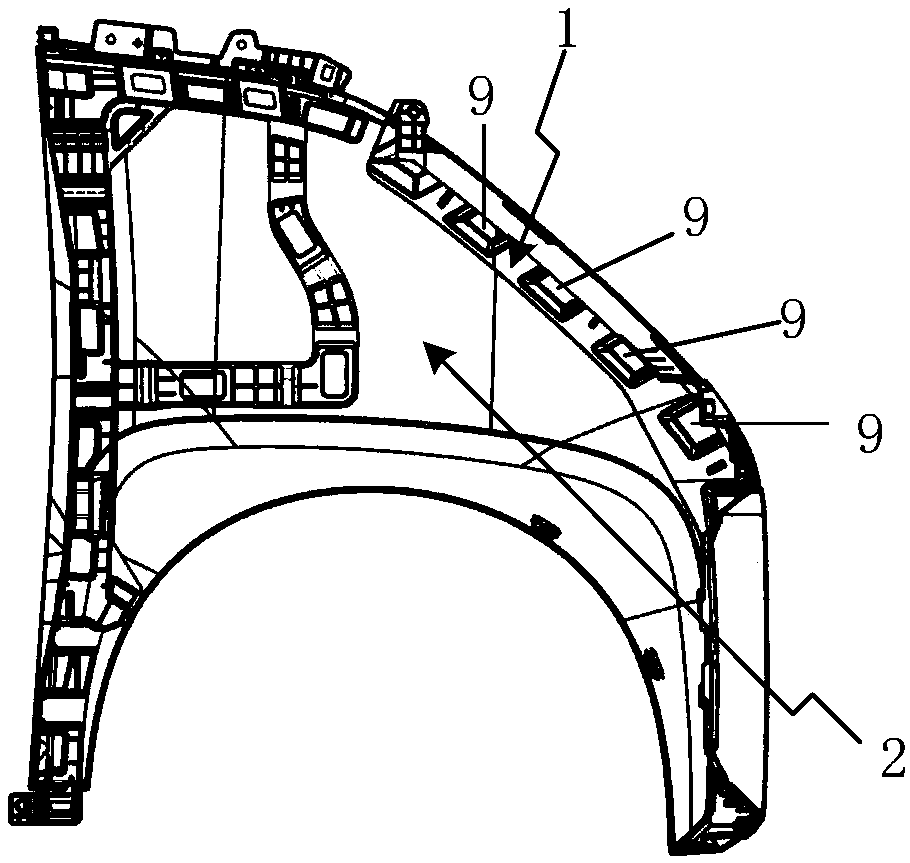

[0037] The following with attached Figure 3 to Figure 11 A fender front mounting bracket of the present invention is further described in detail. image 3 The right side is front, the back side is back, the upper side is up, and the lower side is down.

[0038] A fender front mounting bracket of the present invention, please refer to Figure 3 to Figure 11 As shown, the front mounting bracket body 1 is included, the front mounting bracket body 1 extends obliquely and longitudinally and is fixed on the upper edge of the front side of the fender body 2, and the upper end of the upper side wall of the front mounting bracket body 1 is provided with an inward The first mounting bracket 3 extending longitudinally, the middle and lower end of the upper side wall of the front mounting bracket body 1 is provided with the second mounting bracket 4 extending longitudinally inwards, the front mounting bracket body 1 is connected to the corresponding front grille assembly side The wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com