A kind of concrete anticorrosion agent and preparation method thereof

An anti-corrosion agent and concrete technology, applied in the field of concrete, can solve the problems of social resource waste and economic loss, and achieve the effects of delaying the corrosion of steel bars, improving the carbonization resistance and structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

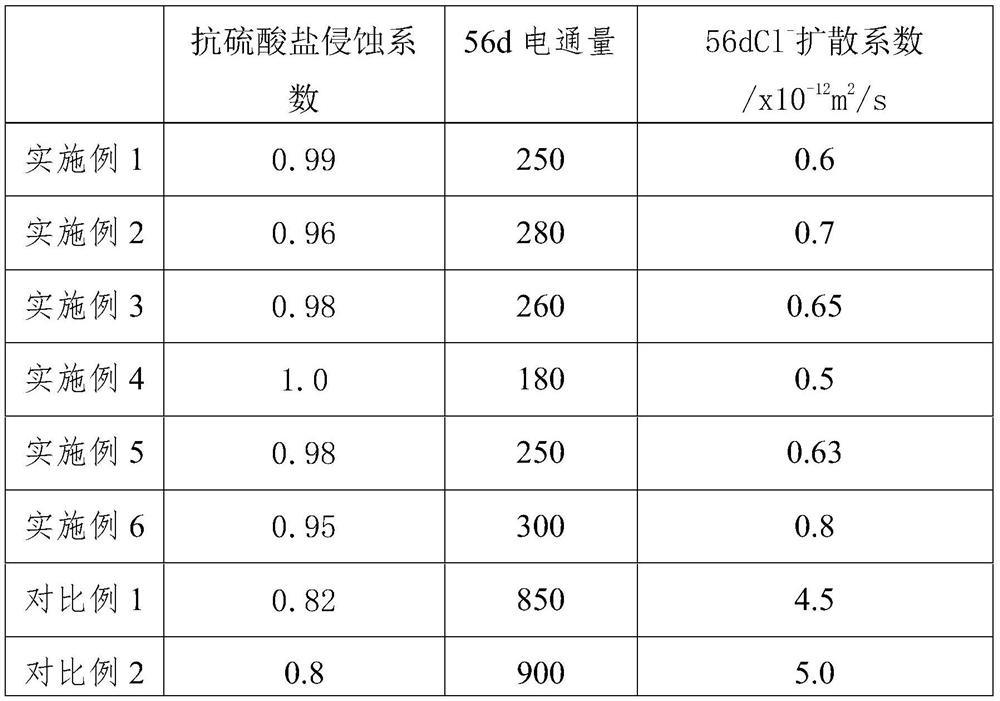

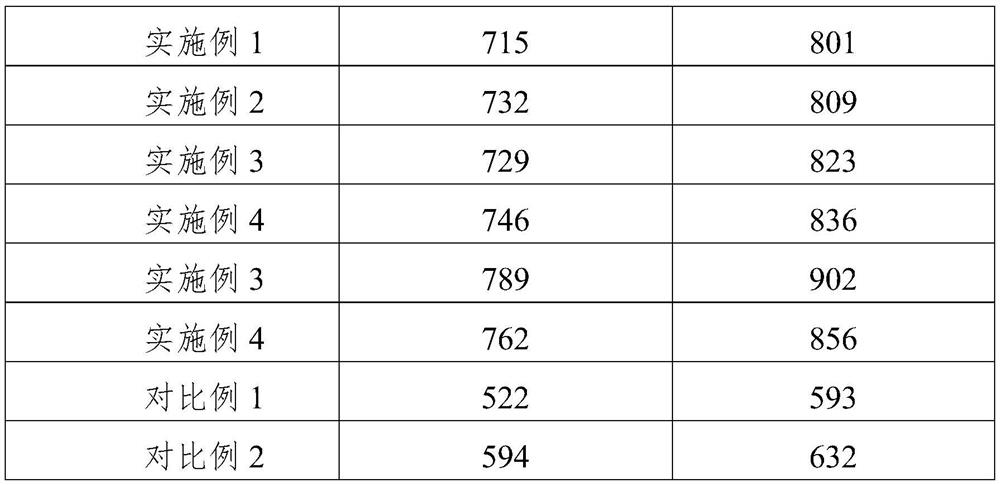

Examples

Embodiment 1

[0024] A concrete anticorrosion agent, which is made of the following components by weight percentage: TK-PCA type polycarboxylic acid series high-performance water reducer 3%, hydroxyl-terminated hyperbranched polyamide ester 3%, fatty acid acyldiethanolamine 0.5%, nanometer two Silicon oxide 2%, hydroxypropyl methylcellulose 1.2%, isooctyltriethoxysilane 0.15%, triethanolamine 0.1%, and the balance is fly ash.

[0025] The average particle size of nano-silica is 50nm; the average particle size of fly ash is 80μm.

[0026] The preparation method of the anticorrosion agent for concrete comprises the following steps: firstly mix polycarboxylate water reducer, hydroxypropyl methylcellulose, fatty acyldiethanolamine, triethanolamine and fly ash evenly to obtain premixed powder; The premixed powder, hydroxyl-terminated hyperbranched polyamide ester, nano silicon dioxide, and isooctyltriethoxysilane are placed in a high-speed mixer and mixed evenly to obtain the concrete corrosion ...

Embodiment 2

[0028] A concrete anti-corrosion agent, made of the following ingredients in weight percentage: 6% of SP-40 type polycarboxylate high-performance water reducer, 2% of hydroxyl-terminated hyperbranched polyamide ester, 0.2% of fatty acid acyldiethanolamine, nanometer two Silicon oxide 3%, hydroxypropyl methylcellulose 0.5%, isooctyltriethoxysilane 0.2%, triethanolamine 0.15%, and the balance is fly ash.

[0029] The average particle diameter of the nano silicon dioxide is 30nm; the average particle diameter of the fly ash is 10μm.

[0030] The preparation method of concrete corrosion inhibitor is the same as embodiment 1.

Embodiment 3

[0032] A concrete anticorrosion agent, which is made of the following ingredients in weight percentage: 5% of SP-40 type polycarboxylic acid series high-performance water reducing agent, 4.8% of hydroxyl-terminated hyperbranched polyamide ester, 0.6% of fatty acid acyldiethanolamine, nanometer two Silicon oxide 2%, hydroxypropyl methylcellulose 1.6%, isooctyltriethoxysilane 0.1%, triethanolamine 0.2%, and the balance is fly ash.

[0033] The average particle size of nano-silica is 60nm; the average particle size of fly ash is 50μm.

[0034] The preparation method of concrete corrosion inhibitor is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com