Rock-soil mixed vertical shaft engineering supporting system and vertical shaft construction method

A construction method and shaft technology, which can be used in shaft equipment, earth-moving drilling, wellbore lining, etc., can solve problems such as hidden safety hazards and insufficient supporting rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

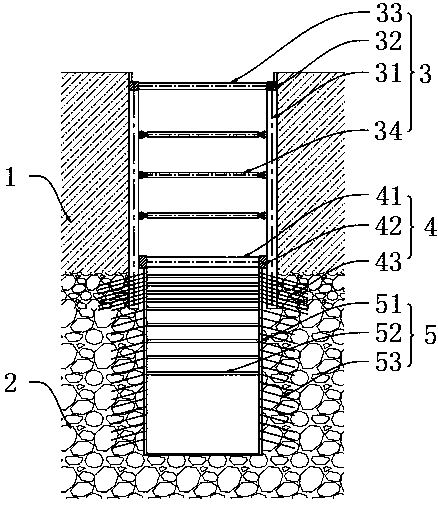

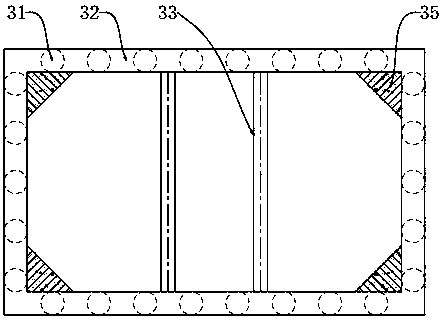

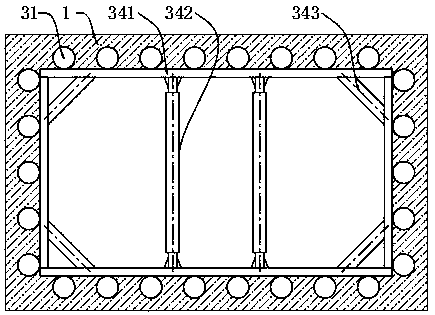

[0038] see figure 1 , a rock-soil mixed shaft engineering support system provided by the present invention includes a soil layer support structure 4 positioned at the upper soil layer, a rock-soil connection support structure 4 positioned at the rock-soil interface and a rock layer support positioned at the lower rock layer Structure 5. The soil layer support structure 4 includes an enclosure pile 31 , a crown beam 32 , a first support 33 and a second support 34 . The surrounding protection piles 31 have multiple and are arranged along the edge of the shaft, and the bottom ends of a plurality of the surrounding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com