An alkali metal heat pipe driven by an electromagnetic pump and its heat transfer method

An auxiliary drive, electromagnetic pump technology, applied in the field of heat transfer in nuclear reactor engineering, can solve problems such as high cost and process limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is further introduced:

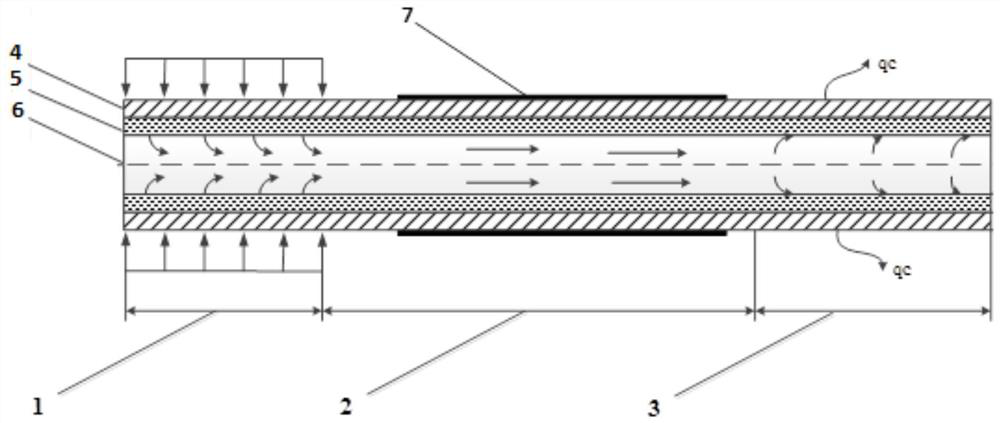

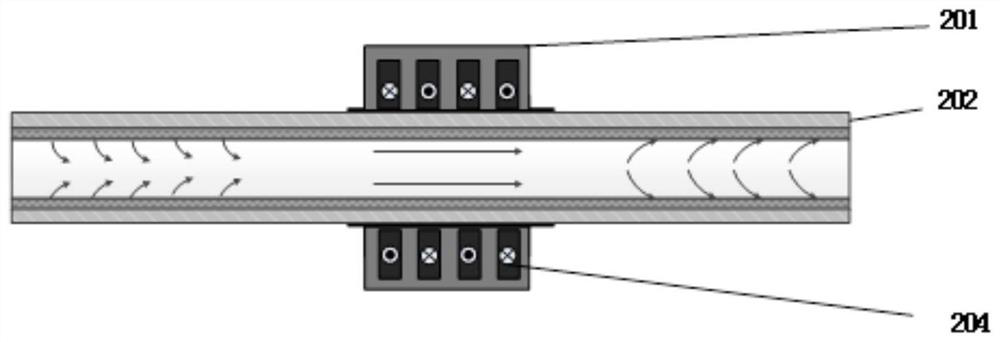

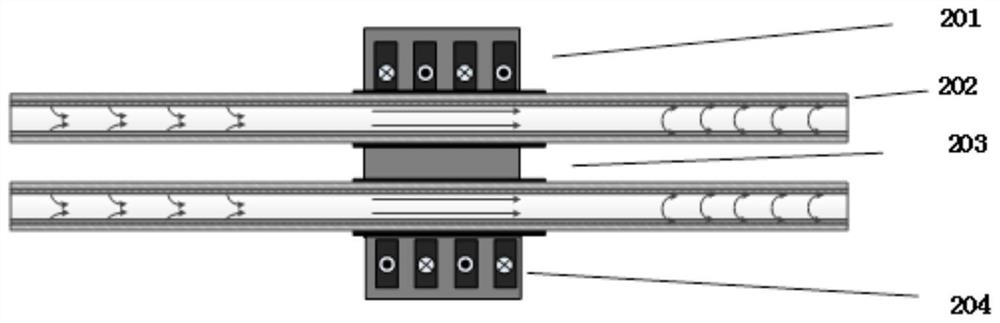

[0027] An alkali metal heat pipe driven auxiliary by an electromagnetic pump, comprising: a power supply, an electromagnetic pump, and a heat pipe 202, the electromagnetic pump is looped on the outer surface of the heat pipe 202, and the power supply is connected to the electromagnetic pump; the heat pipe 202 also includes: a heat pipe casing 4. Heat pipe liquid-absorbing core 5, heat pipe central air cavity 6 and insulation layer 7; inside the heat pipe shell 4 is the heat pipe central air cavity 6; heat pipe central air cavity 6 is provided with a heat pipe liquid-absorbing core 5; heat pipe shell 4 The outer middle part of the electromagnetic pump is provided with an insulating layer 7; the electromagnetic pump also includes: an electromagnetic pump groove, a primary iron core 201, an inner layer iron core 203 and a winding 204; the outer wall of the electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com