A fault image recognition method for the breakage of the railway wagon hook lifter

A railway freight car and image recognition technology, which is applied in image enhancement, image analysis, image data processing, etc., can solve the problem of low detection efficiency and achieve the effect of improving efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

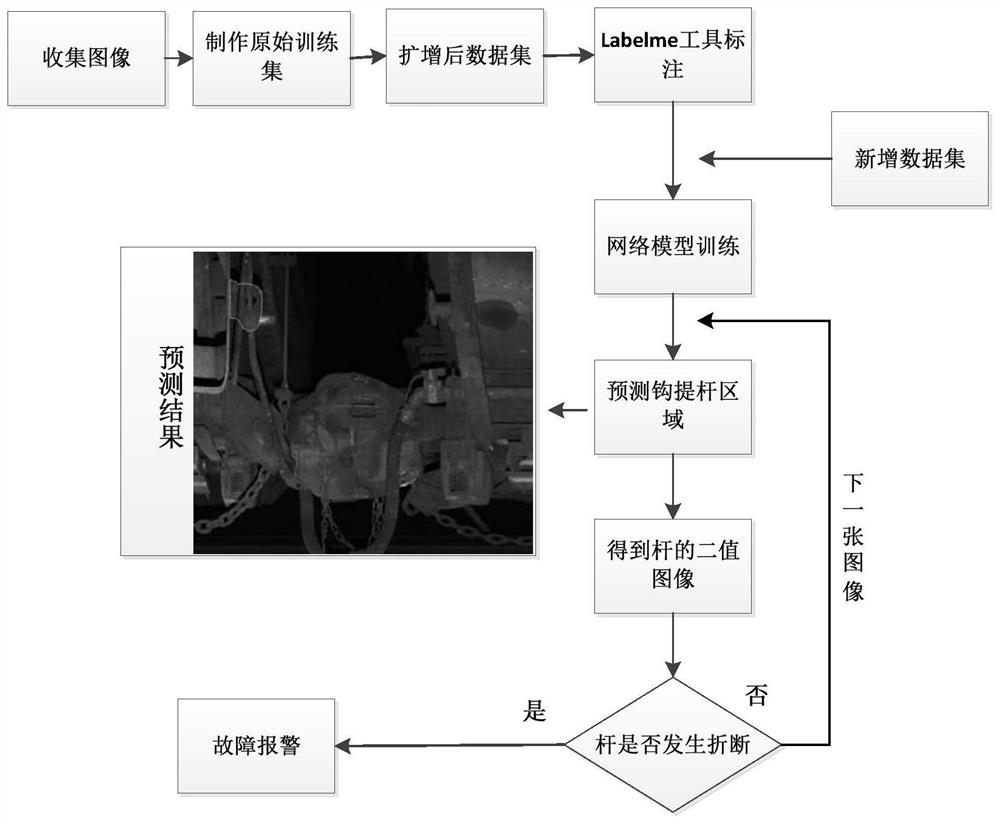

[0037] Specific implementation mode one: refer to Figure 1 to Figure 4 Specifically illustrate the present embodiment, a kind of railway wagon hook lifting rod broken fault image recognition method described in the present embodiment, comprises the following steps:

[0038] Step 1: Obtain the image of the area where the hook handle is located as a sample data set;

[0039] Step 2: Perform data amplification on the sample data set;

[0040] Step 3: Label the images in the dataset;

[0041] Step 4: Generate a data set from the original image and the labeled image, and train the model;

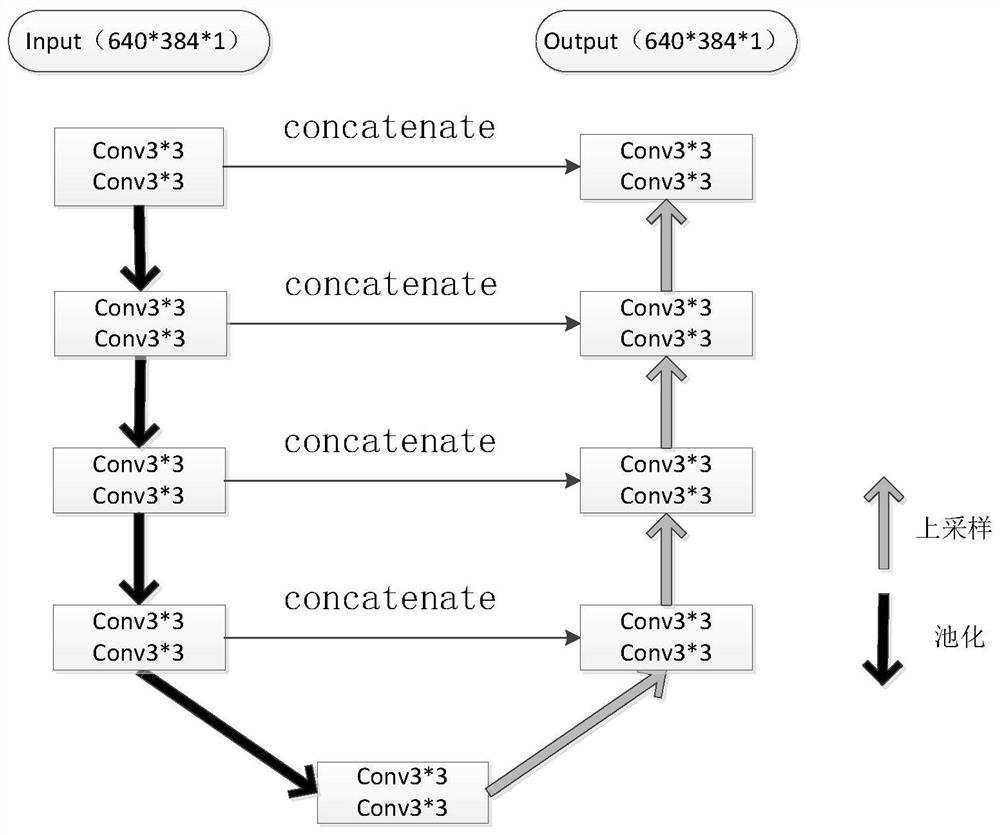

[0042] Step 5: Use the UNet network model to predict the area of the hook lift bar, and obtain the binary image of the hook lift bar;

[0043] Step 6: Determine whether the hook lifting rod is broken, if so, give a fault alarm, otherwise, go to step 5.

[0044] 1. Collect the raw data of the hook lift rod

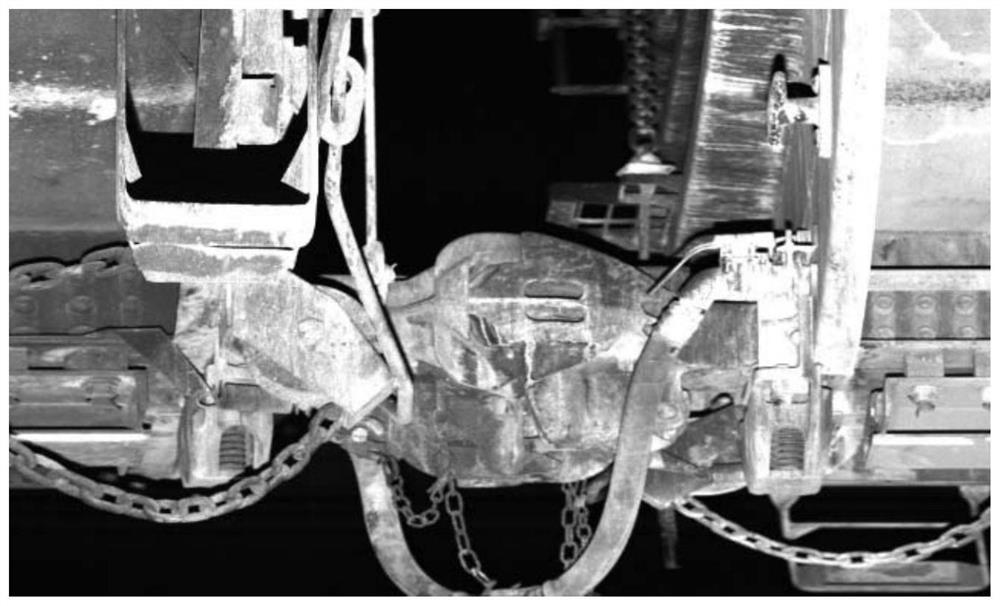

[0045] The grayscale images collected by the high-definition line array camera are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com