A kind of distribution box with buffer function used in construction site

A technology for construction sites and distribution boxes, applied in substation/distribution device shells, electrical components, substation/switch layout details, etc., can solve problems such as not having a buffer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

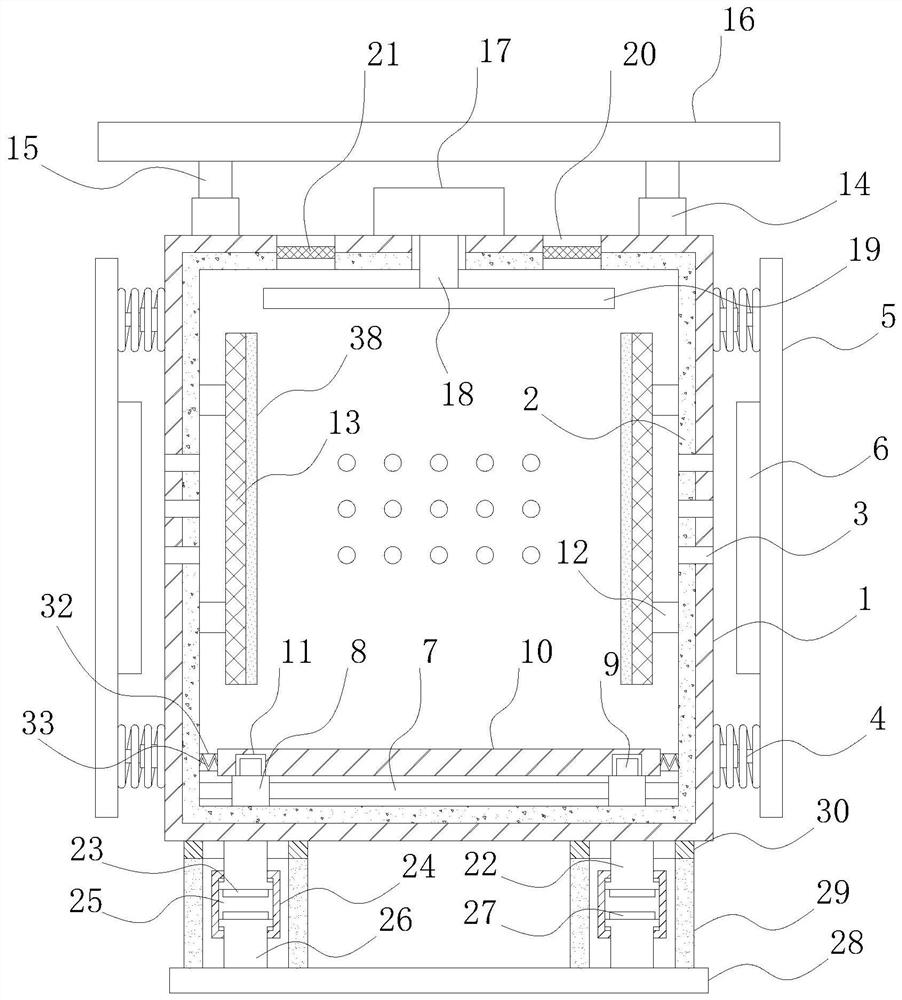

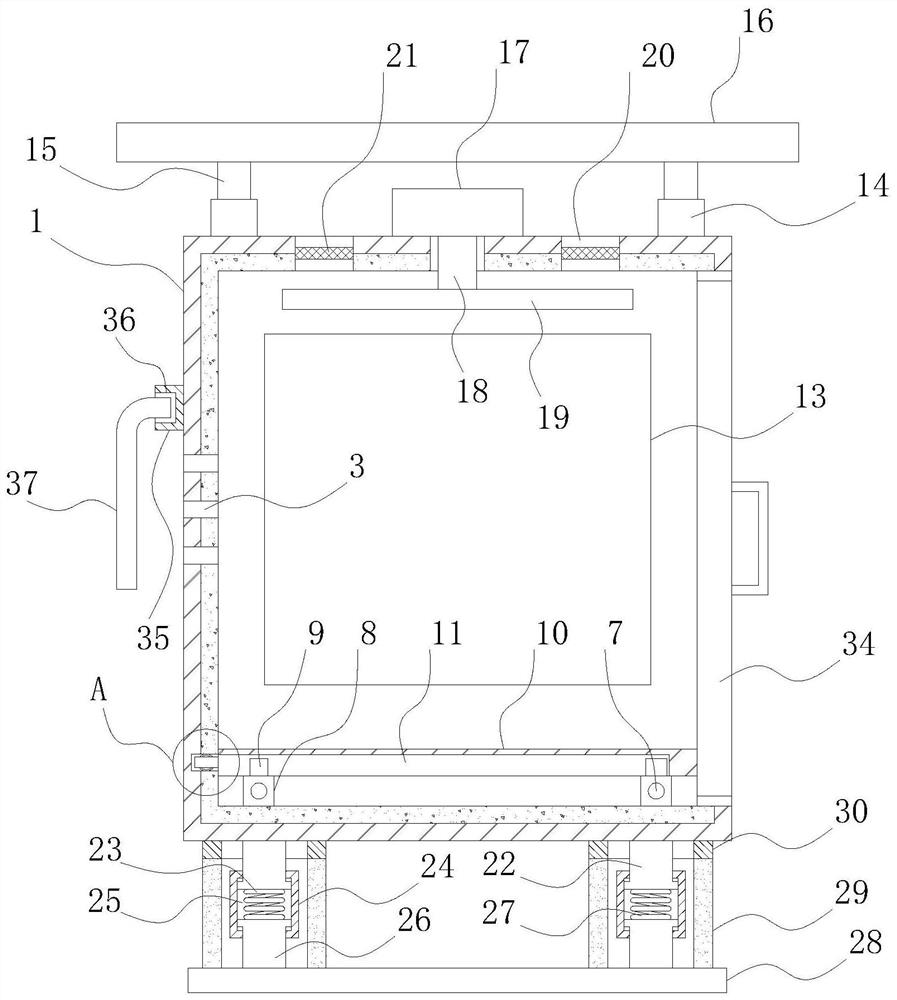

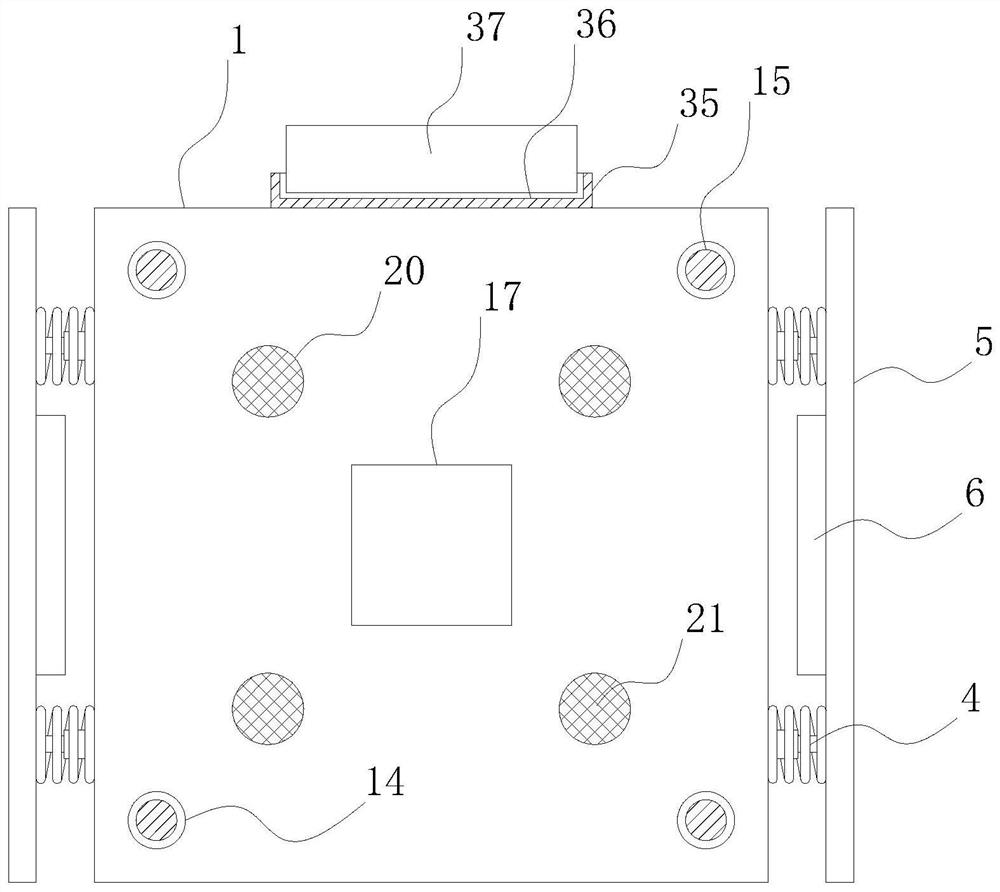

[0023] refer to Figure 1-4 , a distribution box with a buffer function for use on a construction site, including a box body 1, a moisture-proof pad 2 is bonded to the inner surface of the box body 1, through holes 3 are evenly opened around the box body 1, and the box body 1 Both sides of the outer surface are symmetrically welded with buffer springs 4, one end of the buffer spring 4 is welded with an anti-collision plate 5, and the middle part of the anti-collision plate 5 and the buffer spring 4 is welded with a spring pad 6, and the inside of the box body 1 The lower part is symmetrically welded with a fixed rod 7, and the outer surface of the fixed rod 7 is symmetrically welded with a connecting block 8. The top of the connecting block 8 is integrally formed with a clamping block 9, and the clamping block 9 is clamped with a mounting plate 10. The bottom end of the mounting plate 10 There is a first card slot 11 matched with the block 9, and a slider 31 is welded symmetri...

Embodiment 2

[0027] refer to Figure 1-2As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the damping mechanism includes first support columns 22 welded to the four corners of the bottom end of the box body 1, and the bottom ends of the first support columns 22 are welded with first The magnet 23 is slidably connected with a sleeve 24 under the first support column 22, and the middle part of the sleeve 24 is provided with a first chute 25 matched with the first support column 22, and the bottom of the first chute 25 is slidably connected. There is a second support column 26, the top of the second support column 26 is welded with a second magnet 27, the bottom of the second support column 26 is welded with a base plate 28, and the top of the base plate 28 is equipped with an auxiliary shock absorbing mechanism, and the auxiliary shock absorbing mechanism includes Two pairs of hollow elastic columns 29 are welded symmetrically on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com