Vertical feeding wood particle fired baking oven

An oven and feeding technology, applied in the field of ovens, can solve the problems of inconvenient installation and use, bulky, ineffective control of furnace temperature, etc., achieves convenient installation and use, reduces floor space and volume, and ensures high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

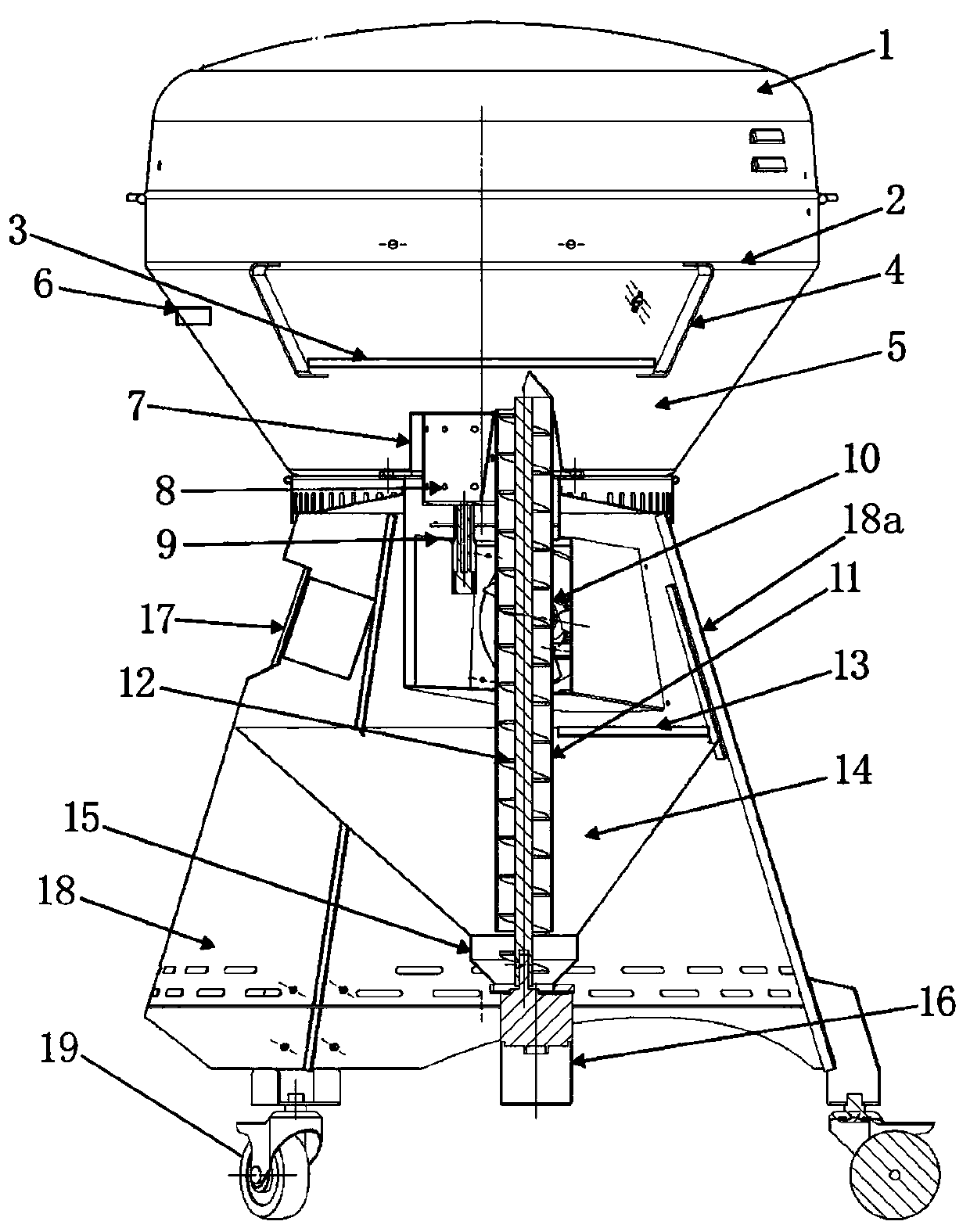

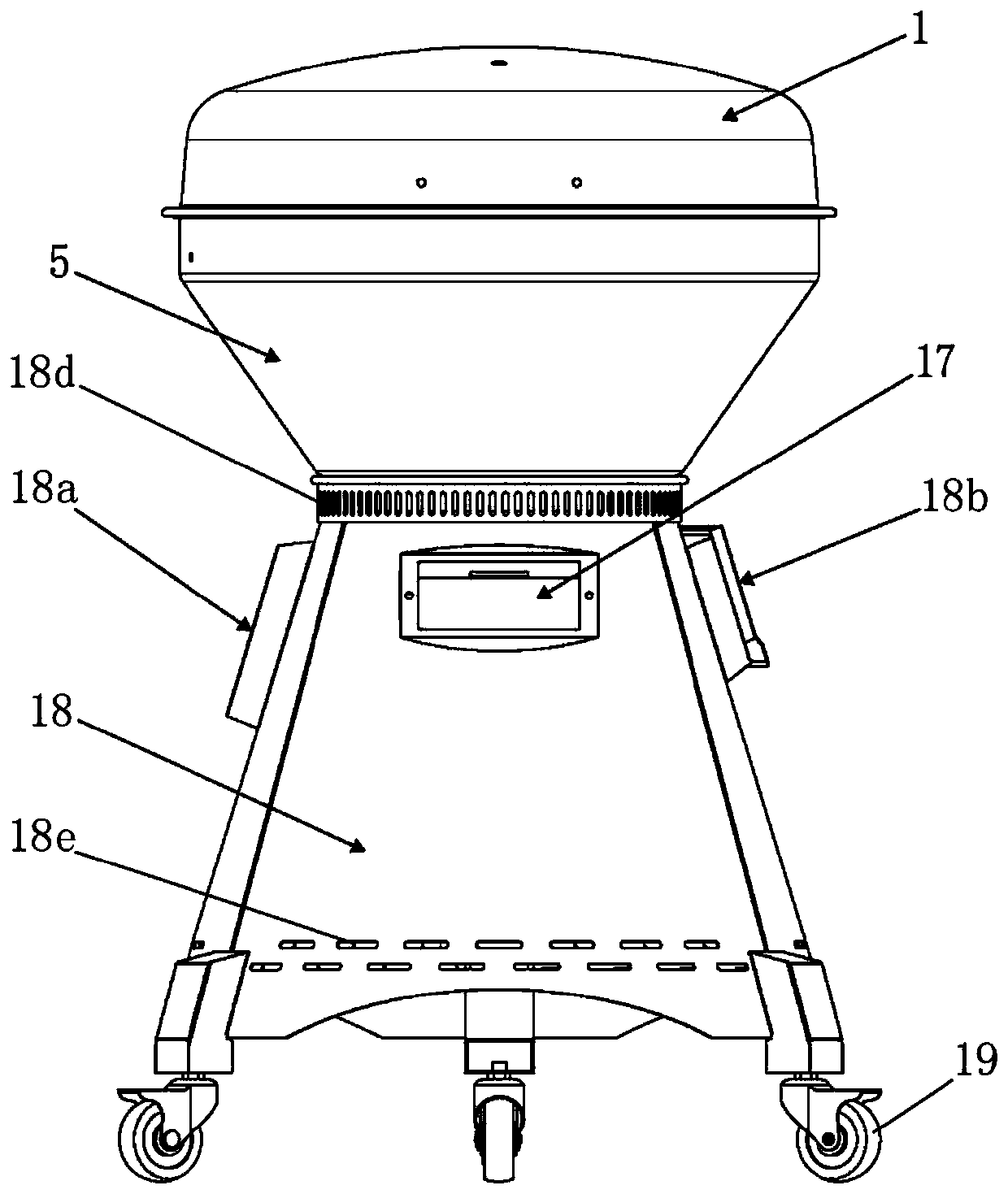

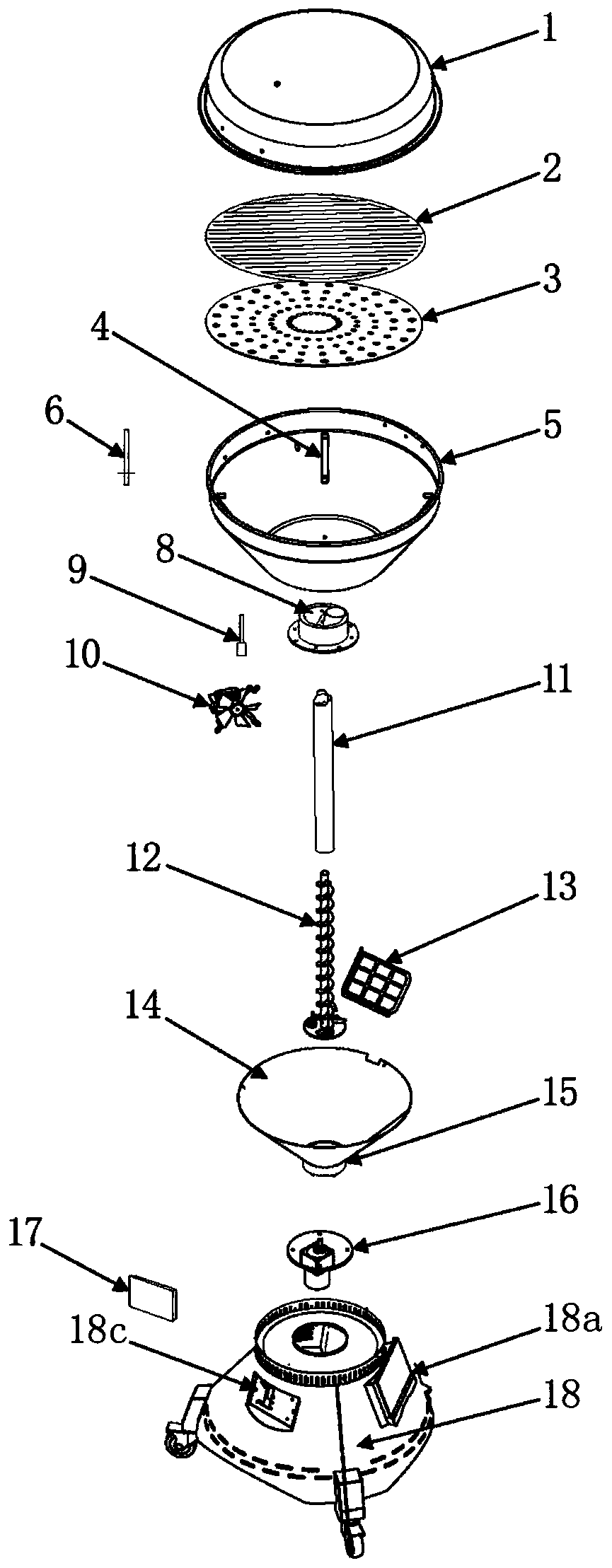

[0035] Refer to attached figure 1 to attach Figure 7 , a wood-fired pellet oven fed vertically, comprising a furnace body assembly, a control circuit board 17 and a housing 18, the furnace body assembly comprising a furnace cover 1 and a baking tray 2 , a soaking pan 3, a furnace body 5 and a main combustion chamber assembly 7, the furnace body 5 is in a funnel-shaped structure, a temperature sensor 6 is provided on the furnace body 5, and a support uniform is provided on the inner wall of the furnace body 5 The pan support 4 of the hot plate 3 and the baking pan 2, the soaking pan 3 and the baking pan 2 are sequentially placed on the pan support 4 from bottom to top; It is a hollow structure, and the side of the housing 18 is provided with a feeding port 18a, a fan maintenance hole 18b and a control circuit board installation hole 18c, and an upper cooling hole 18d is provided on the side of the top of the housing 18. The side of the bottom of the housing 18 is provided wi...

Embodiment 2

[0041] Refer to attached Figure 8 to attach Figure 10 , a vertical feed wood-fired pellet oven, wherein:

[0042] The main combustion chamber assembly 7 in this oven comprises combustion box two 29 and igniter two 30, and igniter two 30 cooperates with combustion box two 29, and described combustion box two 29 comprises sleeve pipe two 29a, flange plate Two 29b and two outer rings 29c, the second sleeve 29a and the second outer ring 29c are fixed on the second flange 29b, the second sleeve 29a is arranged in the middle of the second outer ring 29c, the second sleeve 29a The sleeve port 29a1 on the top is matched with the feed pipe 2 31 of the vertical feeding assembly, the inner wall of the outer ring 29c, the outer side of the sleeve 29a and the top surface of the flange 29b An annular combustion chamber is formed, wherein the inner wall of the second outer ring 29c and the outer surface of the second sleeve 29a form the inner wall of the annular combustion chamber, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com