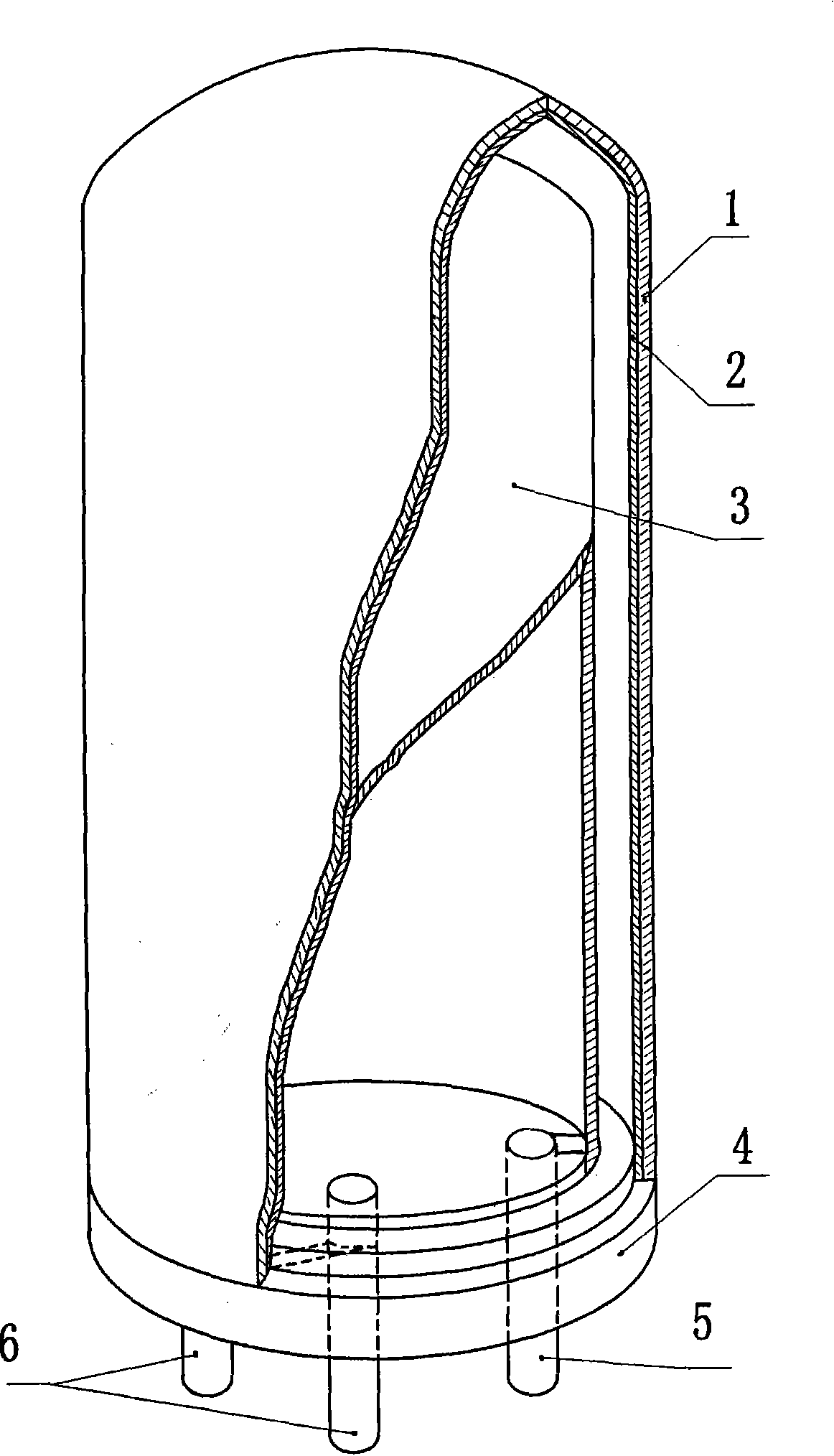

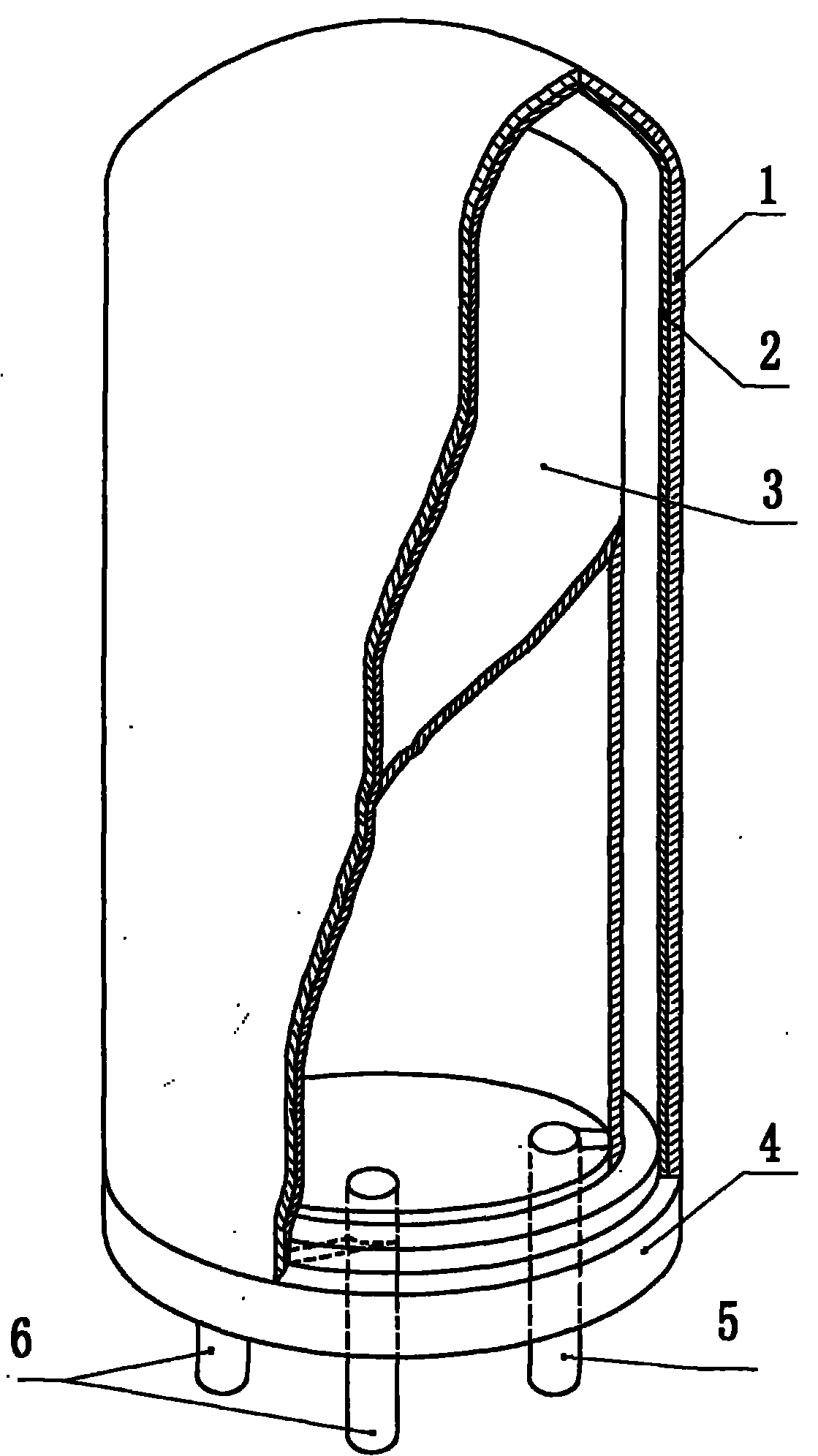

Solar phototube and manufacturing method thereof

A manufacturing method and photoelectric tube technology, which are applied in the field of solar photoelectric tubes to achieve the effects of widening the range, reducing pollution and improving the photoelectric conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 10g of metallic sodium and place it on the tungsten wire heater of the vacuum coating machine, and put the vacuum glass tube mouth down on the coating frame. Then carry out a low vacuum in the bell jar of the coating machine, and the vacuum degree is ≥3×10 -3 mmHg. The vacuum chamber is then evacuated to high vacuum. At the same time, turn on the power supply of the heater, and the heater will heat the diffusion pump oil. The high vacuum time is 60 minutes. Vacuum degree is ≥5×10 - 6 mmHg. Start the tungsten wire heater to heat and vaporize metallic sodium or metallic cesium, and generate gaseous metal to attach to the inner wall of the glass tube to form a coating. The vaporization time is 4 minutes. Then block the tungsten wire heater baffle, and pressurize the tungsten wire heater to remove residual sodium or cesium on the heater. Then carry out high-vacuum treatment to make the coating film attached to the glass tube more firm, and the high-vacuum treatm...

Embodiment 2

[0017] Get 15g of cesium metal and place it on the tungsten wire heater of the vacuum coating machine, and place the vacuum glass tube mouth down on the coating frame. Then carry out a low vacuum in the bell jar of the coating machine, and the vacuum degree is ≥3×10 -3 mmHg. The vacuum chamber is then evacuated to high vacuum. At the same time, turn on the power supply of the heater, and the heater will heat the diffusion pump oil. The high vacuum time is 60 minutes. Vacuum degree is ≥5×10 - 6 mmHg. Start the tungsten wire heater to heat and vaporize metallic sodium or metallic cesium, and generate gaseous metal to attach to the inner wall of the glass tube to form a coating. The vaporization time is 3 minutes. Then block the tungsten wire heater baffle, and pressurize the tungsten wire heater to remove residual sodium or cesium on the heater. Then carry out high-vacuum treatment to make the coating film attached to the glass tube more firm, and the high-vacuum treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com