An environment-friendly artificial quartz stone manufacturing hollow column forming mold

A technology of artificial quartz stone and forming mold, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high manufacturing cost, high wear degree, low durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

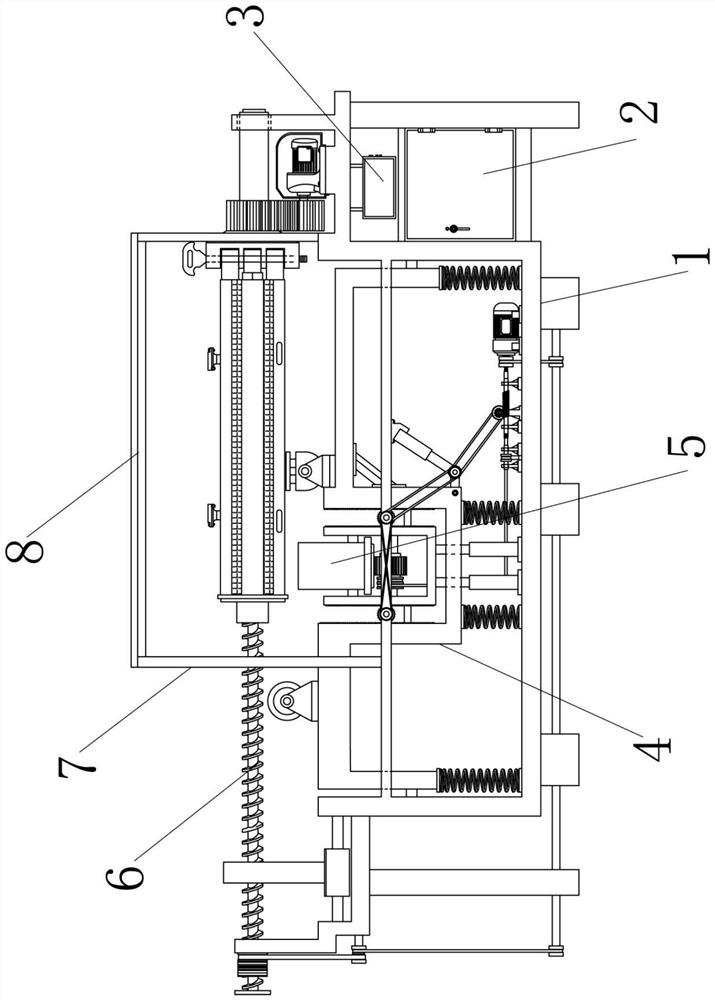

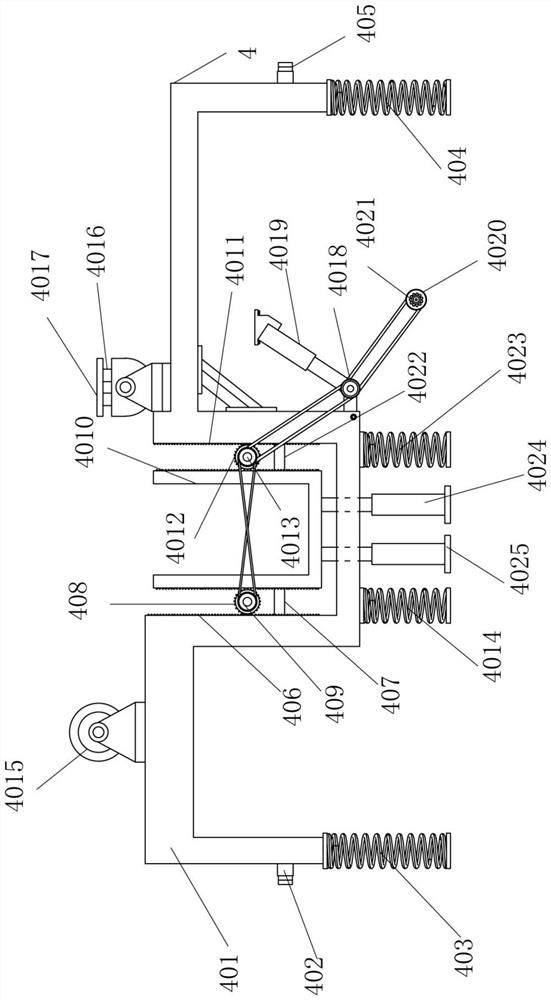

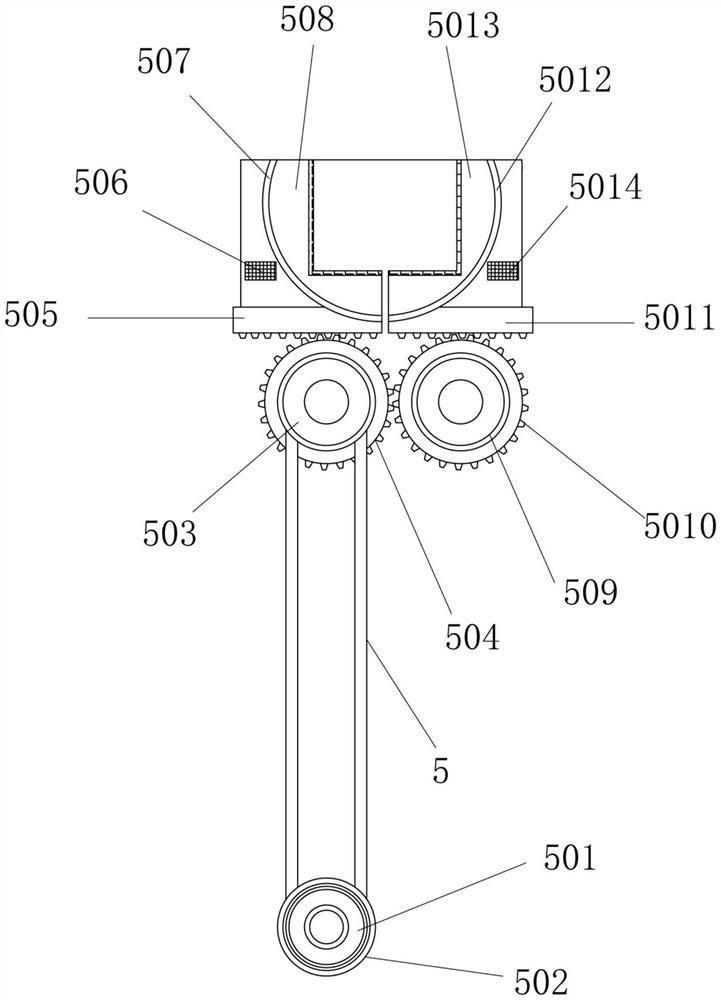

[0029] An environment-friendly artificial quartz stone manufacturing hollow column forming mold, including an outer frame 1, a storage cabinet 2, a control panel 3, a replacement cycle support mechanism 4, a centrifugal follow-up clamping mechanism 5, a replacement mechanism 6, a heat preservation cover 7 and a top cover 8. A storage cabinet 2 is provided at the inner right bottom of the outer frame 1; a control panel 3 is provided at the inner right middle part of the outer frame 1; a replacement circulation support mechanism 4 is provided at the inner right middle part of the outer frame 1; , the bottom and the left side are connected with the replacement mechanism 6, and the right bottom of the replacement mechanism 6 is connected with the replacement cycle support mechanism 4; the right side of the outer surface of the outer frame 1 is bolted to the heat preservation cover 7; A centrifugal follow-up clamping mechanism 5 is arranged on the middle top; a top cover 8 is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com