Liquid packaging container with liquid guide opening structure

A packaging container and liquid technology, applied in the field of liquid packaging containers, can solve problems such as troublesome operation, complex structure of the anti-pollution inner cover, etc., and achieve the effect of avoiding waste, simple and reasonable structure, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

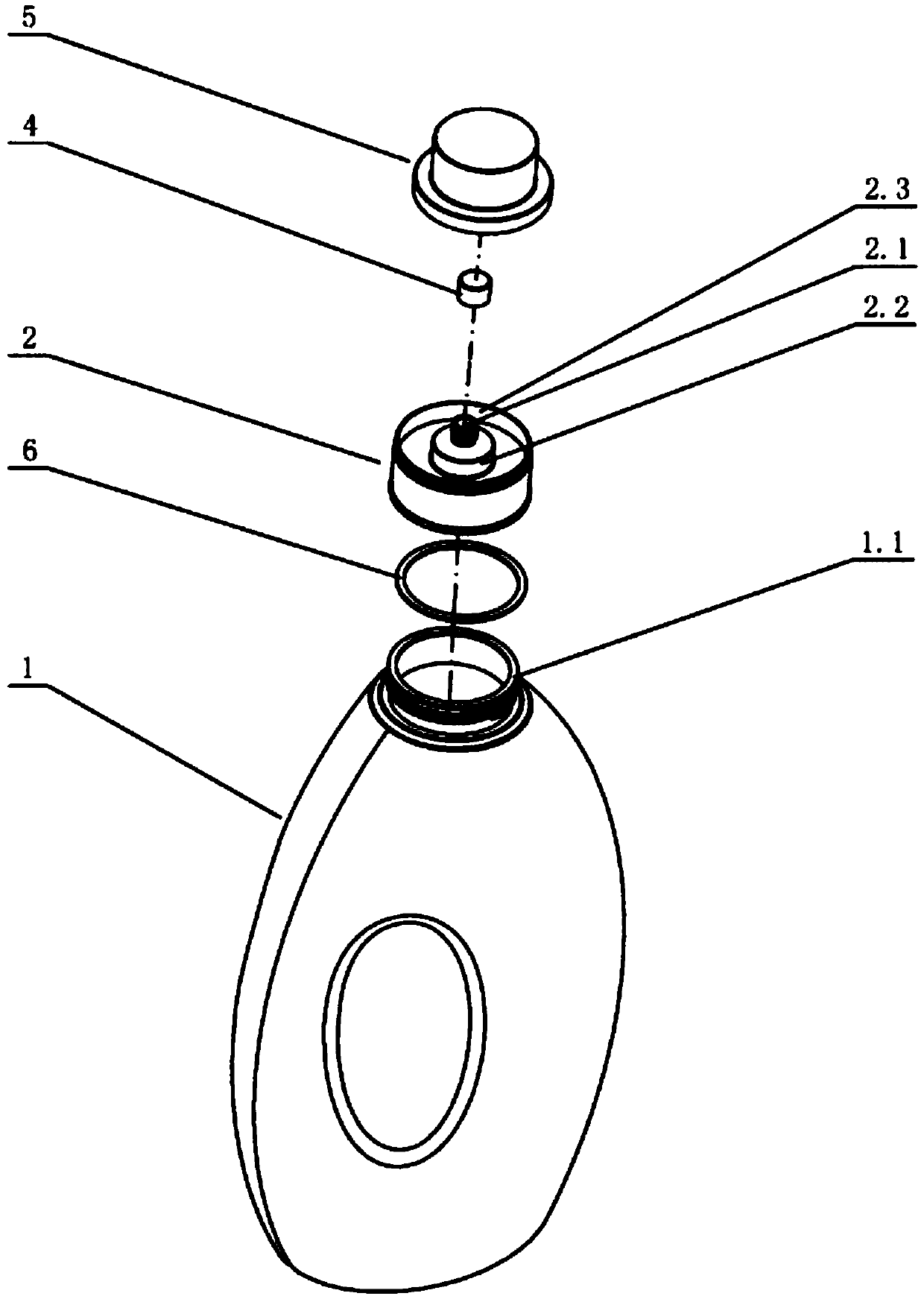

[0028] see Figure 1-Figure 3 , the liquid packaging container with a liquid guide port structure, including an outer cover 5 arranged on the bottle body 1, and an inner cover 2, the inner cover 2 is connected to the bottle mouth 1.1 of the bottle body 1, and the outer cover 5 covers Connected to the inner cover 2 or the bottle body 1; the inner cover 2 is provided with a liquid outlet 2.1 communicating with the bottle mouth 1.1, and the flow area of the liquid outlet 2.1 is much smaller than that of the bottle mouth 1.1.

[0029] In this embodiment, a sealing ring 6 is also provided between the inner cap 2 and the bottle mouth 1.1.

[0030] A sealing cover 4 is also arranged between the outer cover 5 and the inner cover 2, and the sealing cover 4 is connected to the liquid outlet 2.1.

[0031] The inner cover 2 is provided with a hollow boss 2.2, and the liquid outlet 2.1 is arranged on the hollow boss 2.2.

[0032] The maximum inner diameter of the hollow boss 2.2 is bet...

no. 2 example

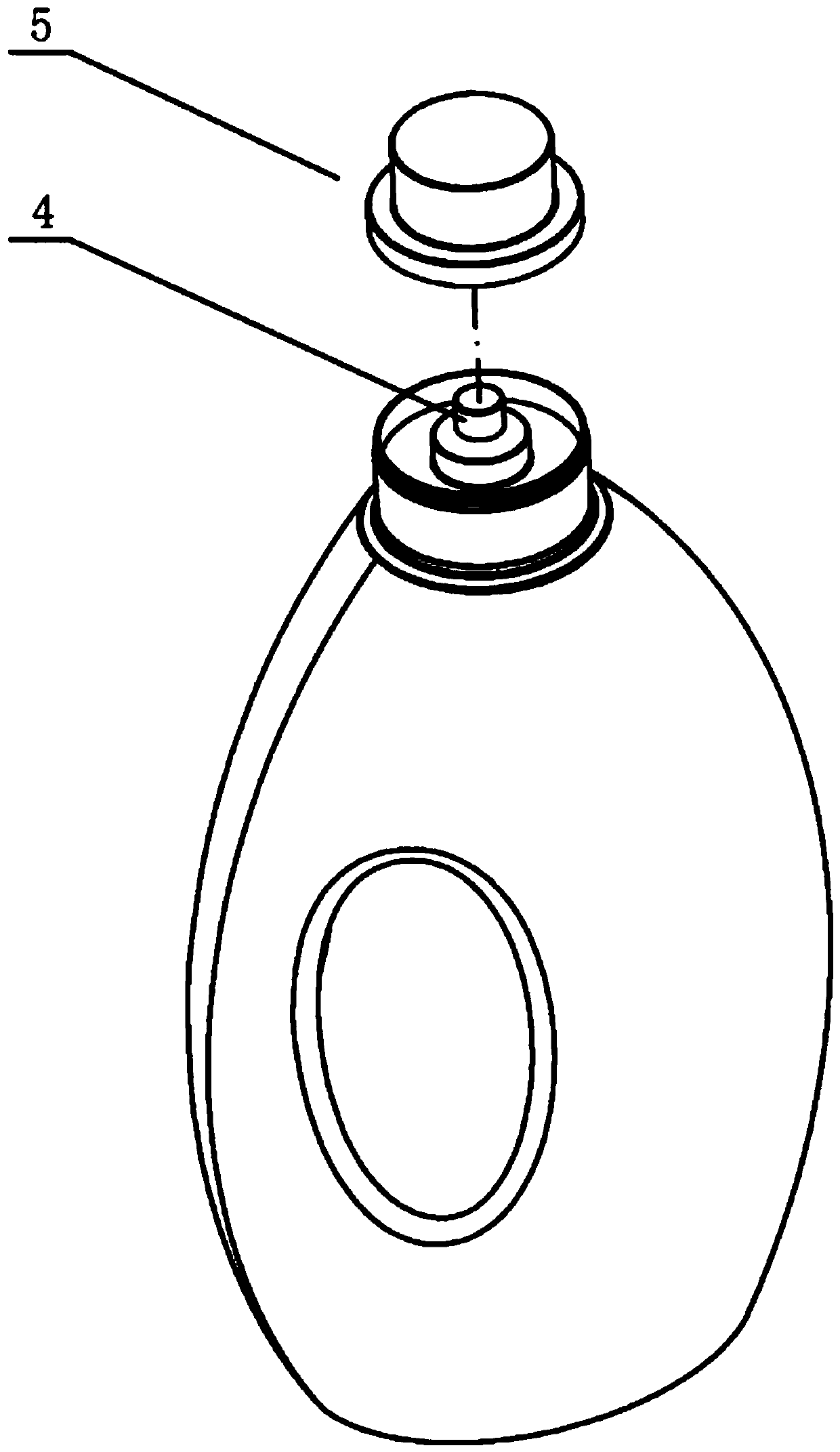

[0037] see Figure 4-Figure 5 , in this embodiment, the liquid packaging container with a liquid guide structure further includes a bezel 3, which is crimped between the sealing cover 4 and the liquid outlet 2.1. During specific manufacture, the blank holder 3 and the sealing cover 4 can be crimped together.

[0038] Refer to the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com