Storage device of mold steel

A technology for storage devices and steel materials, applied in storage devices, devices for coating liquid on the surface, transportation and packaging, etc., can solve the problems of high labor intensity, hidden dangers of steel products, etc., and achieve the effect of convenient fixed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

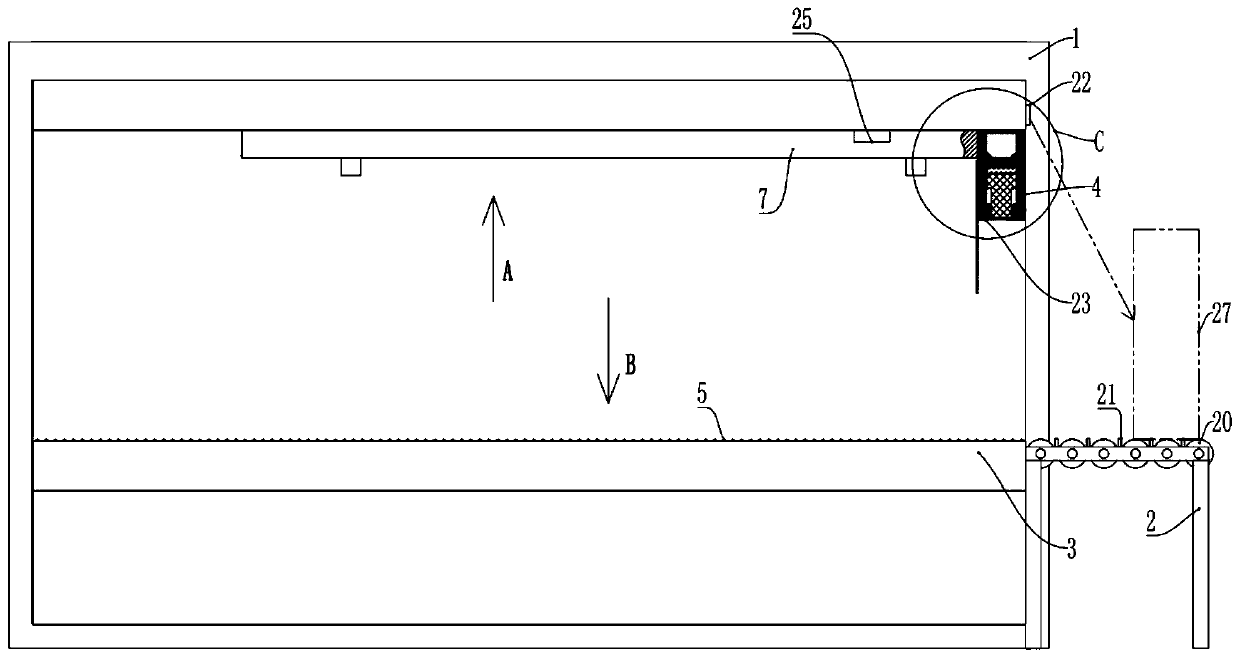

[0037] Embodiment 1 is basically as attached Figure 1 to Figure 5 shown:

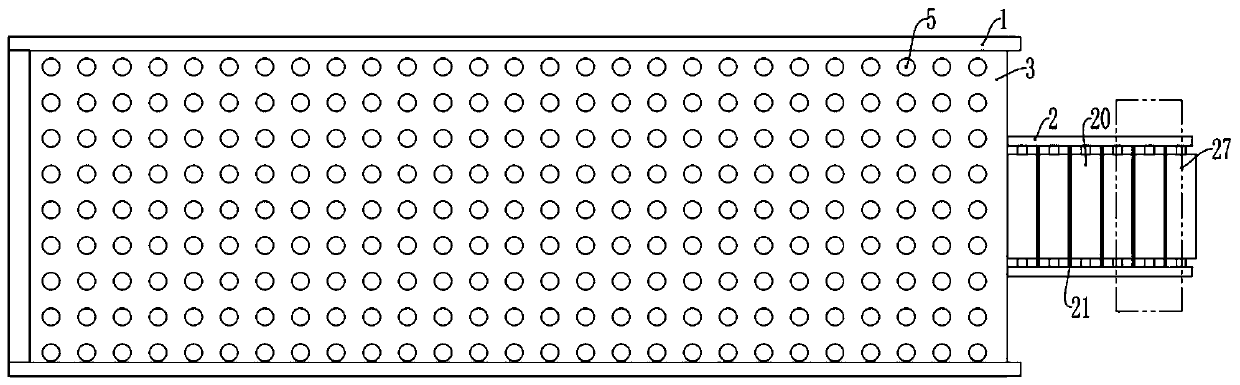

[0038] A storage device for mold steel, including a storage rack 1 and a support rack 2 fixed on the ground by screws, the support rack 2 is located on the right side of the storage rack 1, and a placement platform 3 and a push unit 4 are installed on the storage rack 1, and the storage rack 1 is provided with a placing platform 3 and a pushing unit 4. The platform 3 is fixed and installed on the storage rack 1 by bolts, and the material of the placing platform 3 is 27 steel; there are several balls 5 connected to the placing platform 3 in rotation, that is, the placing platform 3 is a platform with the balls 5, which is convenient for subsequent heavy lifting. Movement of the steel 27 on the placement platform 3 .

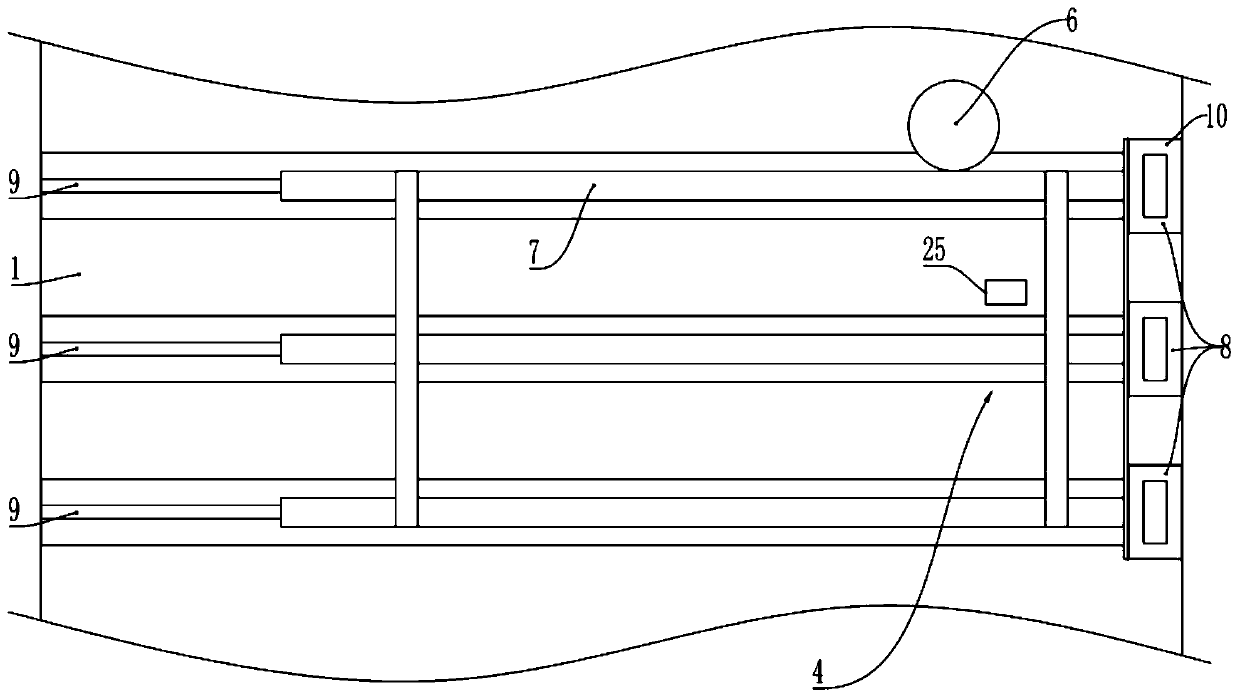

[0039] combine figure 2 and Figure 4 , the push unit 4 includes a motor, a gear 6, a moving frame 7 and a grabbing assembly 8, the motor is fixedly installed on the storage frame, the...

Embodiment 2

[0055] The second embodiment is basically as attached Image 6 As shown, the second implementation is improved on the basis of the first embodiment, and the details are as follows:

[0056] Three layers of placing platforms 3 are installed on the storage rack 1 , and a pushing unit 4 is installed above each placing platform 3 (the pushing unit 4 is installed at the bottom of the previous placing plane), and the bottom of the supporting frame 2 is fixedly connected with a lifting platform 26 .

[0057] The lifting platform 26 drives the support frame 2 to move, so that the rollers 20 can be level with the balls 5 on the corresponding placing platform 3 , so that the steel materials 27 can be stored on the placing platforms 3 of different heights, so that more steel materials 27 can be stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com