Scroll compressor

A technology of scroll compressors and moving scrolls, applied in the field of scroll compressors, can solve problems such as lengthening of compressor axial dimensions, lengthening of eccentric pins, and generation of bending moments, so as to improve reliability, reduce height, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions of the embodiments are merely exemplary and in no way limit the present invention and its application or use.

[0036] The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

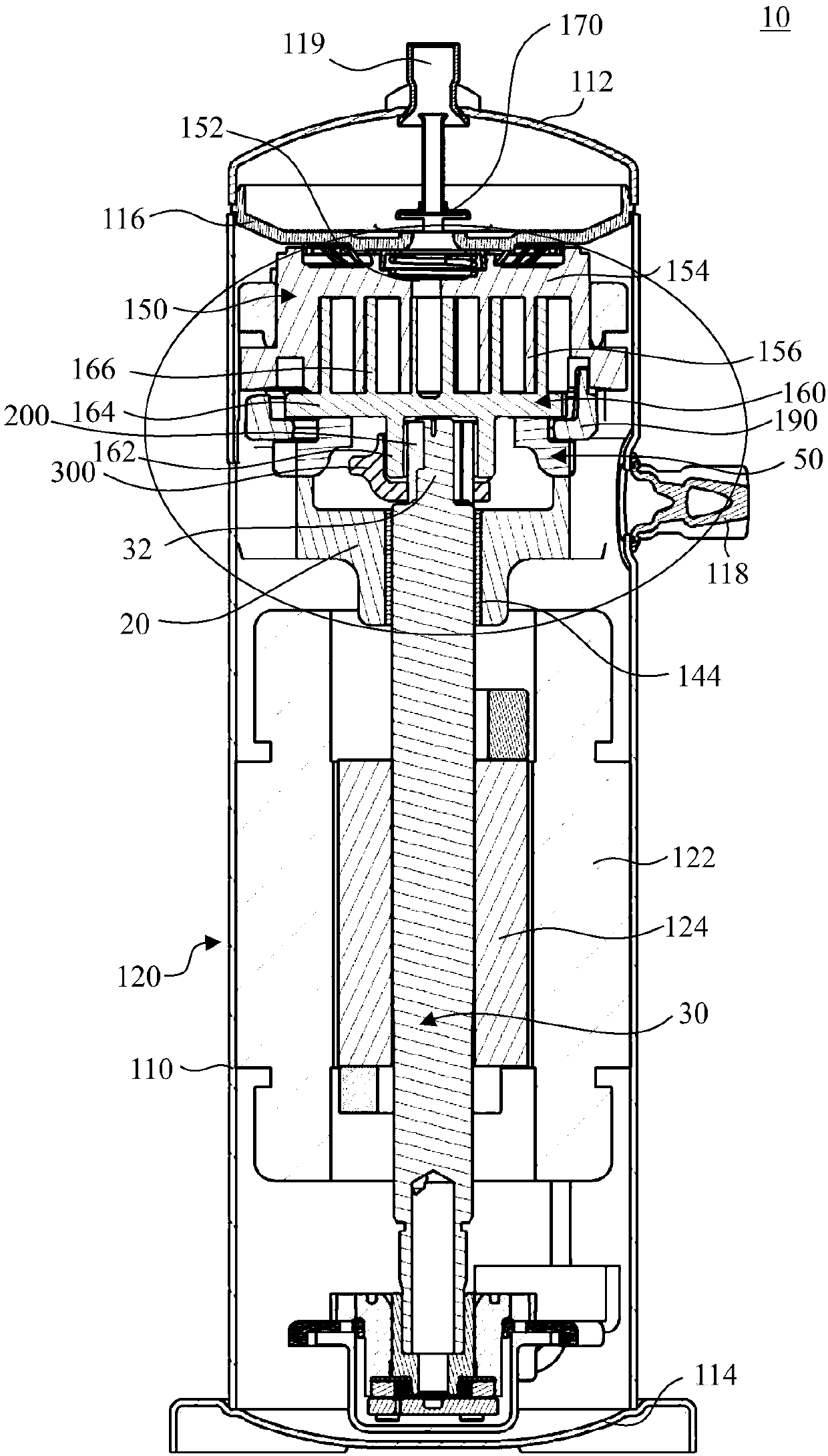

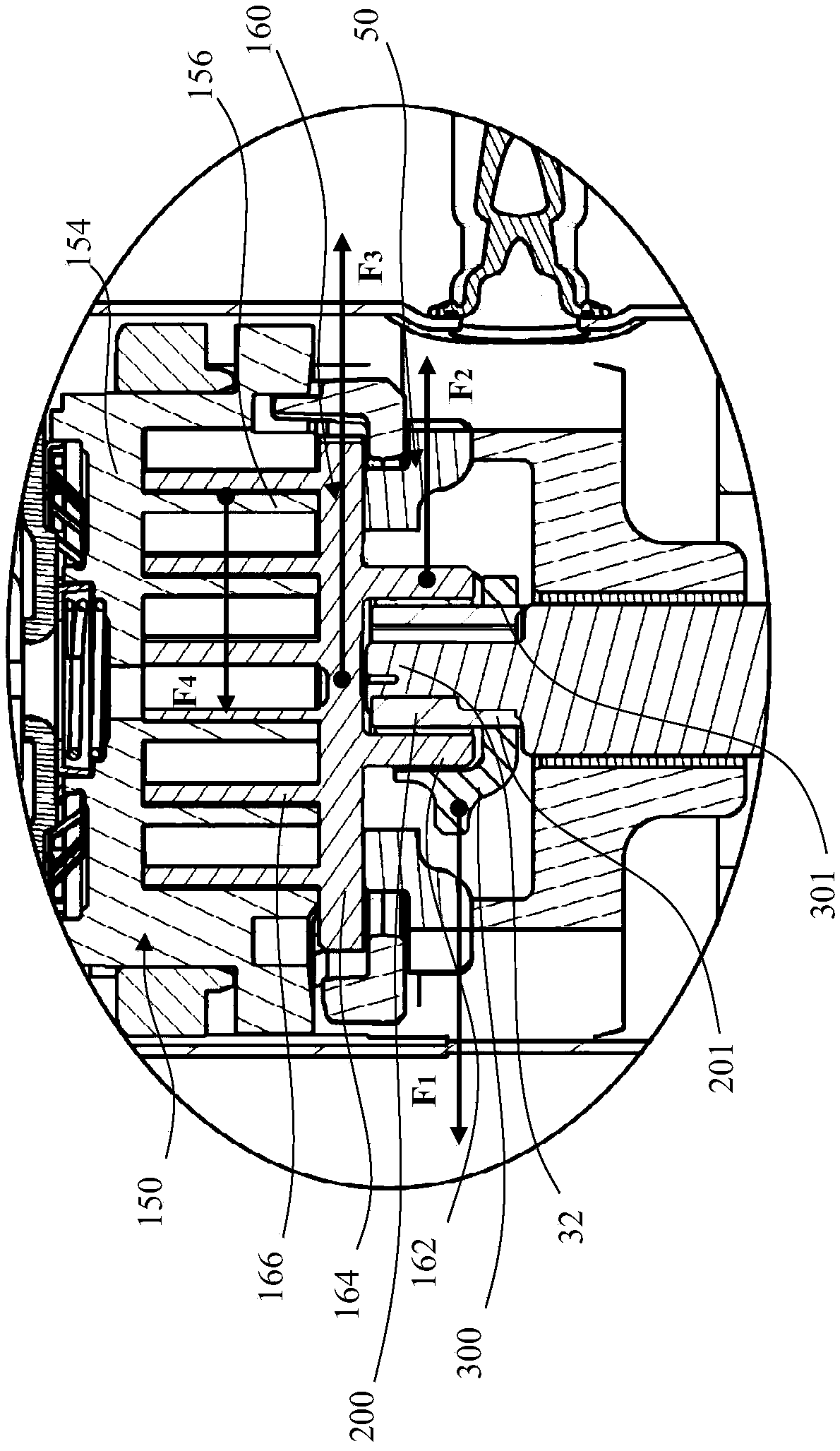

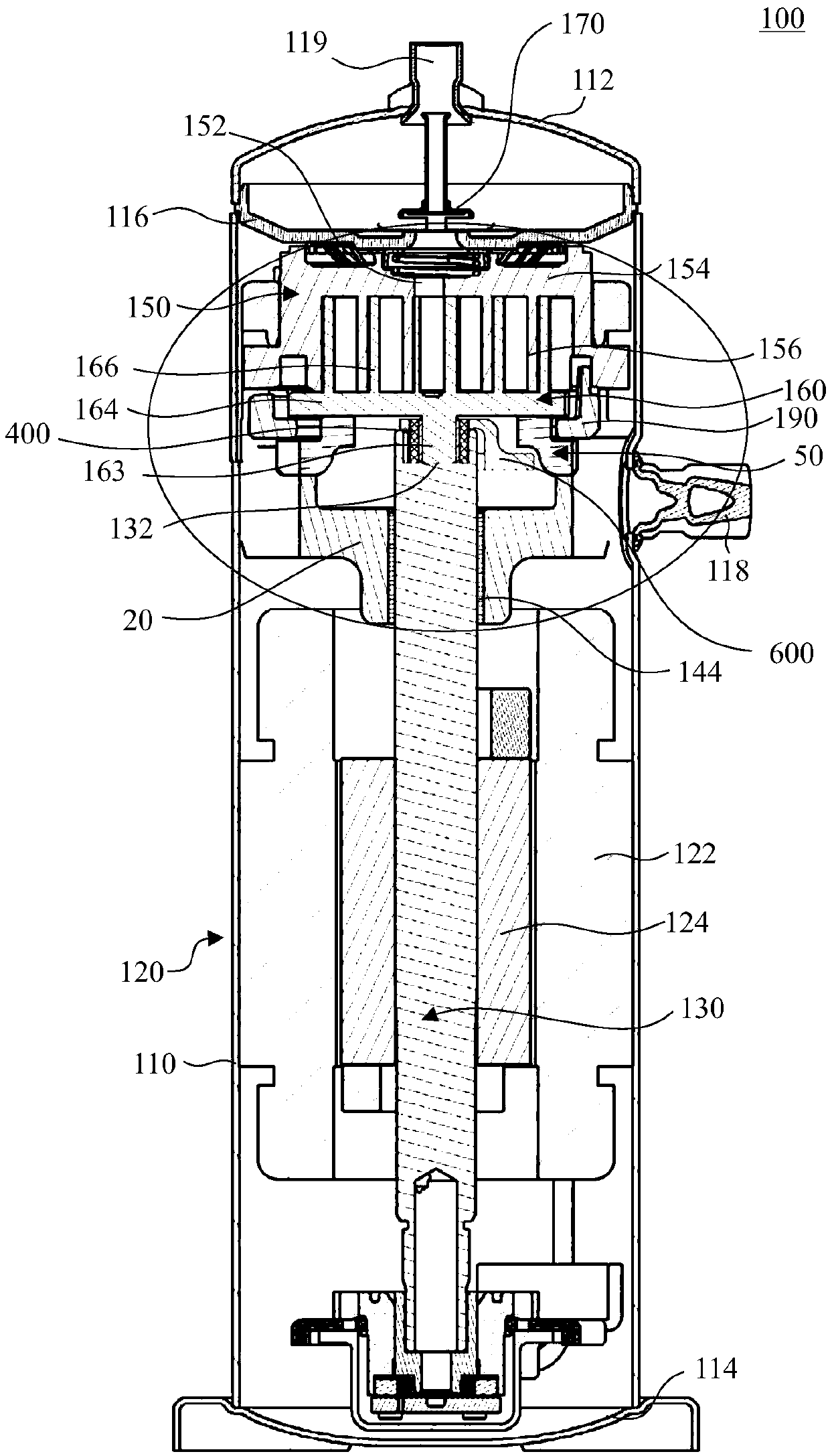

[0037] First, refer to figure 1 with figure 2 A scroll compressor and a counterweight thereof according to the related art are described.

[0038] see figure 1 The scroll compressor 10 generally includes a casing 110, a top cover 112 arranged at one end of the casing 110, a bottom cover 114 arranged at the other end of the casing 110, and a bottom cover 114 arranged between the top cover 112 and the casing 110 so that the compressor The internal space is divided into a high-pressure side and a low-pressure side by a partition 116 . A high pressure side is formed between the partition 116 and the top cover 112 , and a low pressure side is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com