A fast neutron reactor full-stack subchannel geometric modeling method and system

A geometric modeling and sub-channel technology, applied in the field of reactor geometric modeling, can solve the problems of complex fast reactor core structure, difficulty in expressing relevant position coordinates, and difficult geometric information of thermal fluid, etc., to achieve complex structure and simple solution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0075] This embodiment provides a geometric modeling method for the sub-channels of the whole fast neutron reactor, so as to realize a geometric modeling method for the whole core of the hexagonal fast reactor.

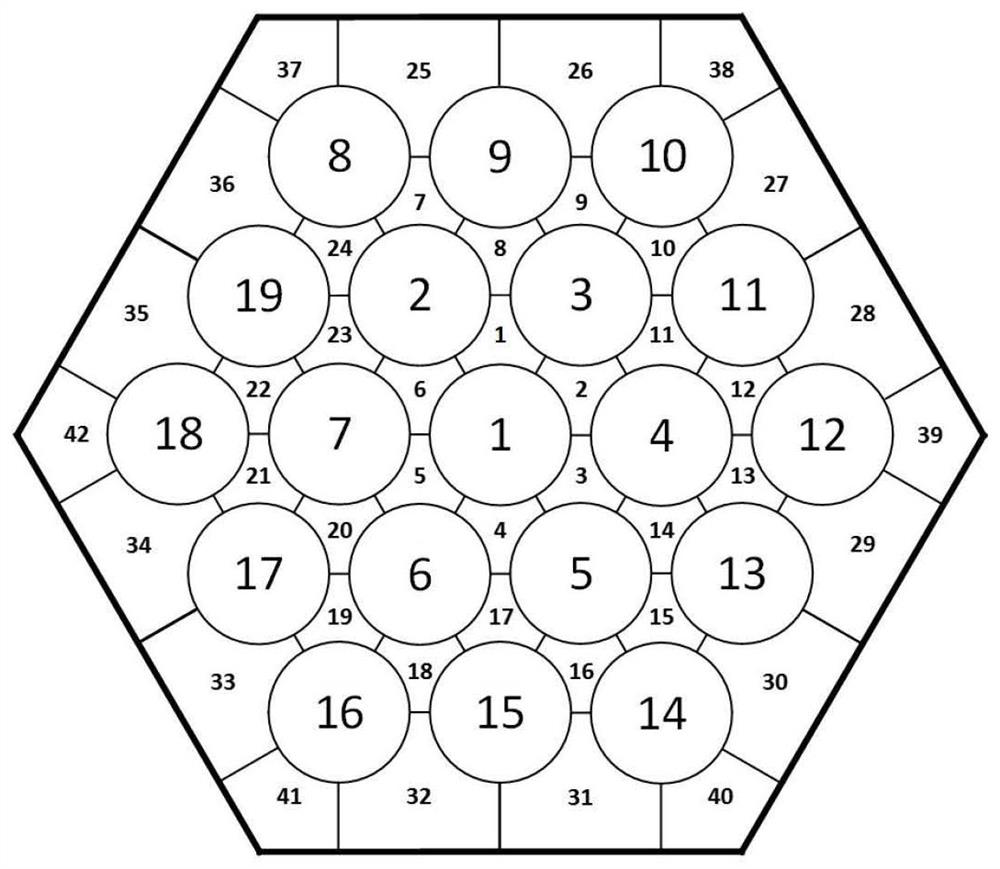

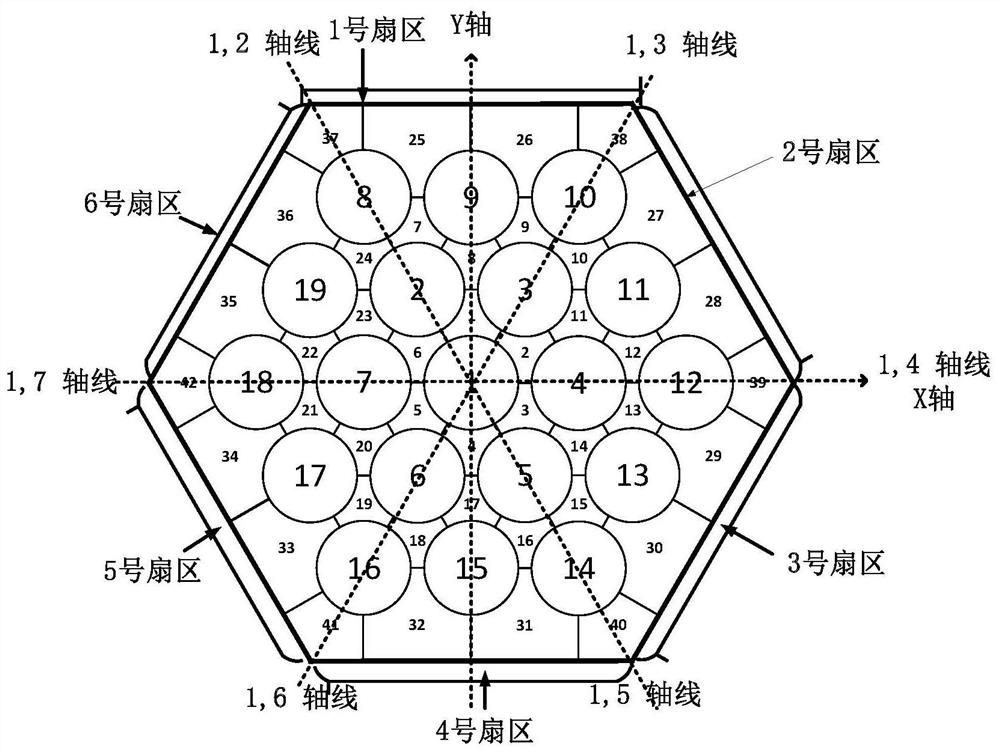

[0076] Each component of the fast reactor core is composed of dozens or hundreds of fuel rods arranged in a hexagonal shape. For more precise calculations, the area surrounded by three rods is generally regarded as a sub-channel, and most of the sub-channels are in the center of an equilateral triangle. channel, but the surrounding boundary near the wall of the box is an irregular shape, which is called side channel and corner channel. Calculate the center coordinates of each component, rod bundle, and sub-channel, use the geometric positional relationship of the core to find out the corresponding functional relational expression, and substitute in the functional relational expression to obtain the center position coordinates. When solving, the outermost sub-channel T...

no. 2 example

[0186] This embodiment provides a fast neutron reactor full-stack subchannel geometric modeling system, which includes:

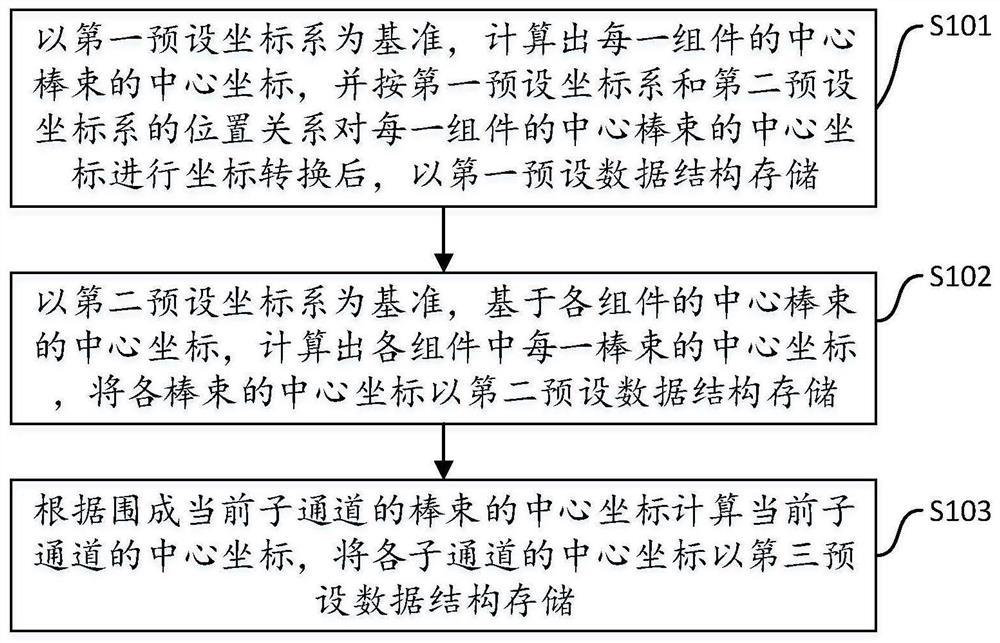

[0187] The component coordinate calculation module is used to calculate the central coordinates of the central rod bundle of each component based on the first preset coordinate system, and store the central coordinates of the central rod bundle of each component in the first preset data structure;

[0188] The rod bundle coordinate calculation module is used to calculate the center coordinates of each rod bundle in each component based on the center coordinates of the central rod bundles of each component based on the second preset coordinate system, and calculate the center coordinates of each rod bundle by storing the second preset data structure;

[0189] The sub-channel coordinate calculation module is used to calculate the center coordinates of the current sub-channel according to the center coordinates of the rod bundles surrounding the current sub-ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap