A kind of anti-clogging method for wet powder feeding

A wet powder and powder technology, which is applied in the field of wet powder blanking and anti-clogging, can solve problems such as clogging of the blanking device, achieve the effects of improving efficiency, reducing the link of cleaning and blocking the material port, and reducing the consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

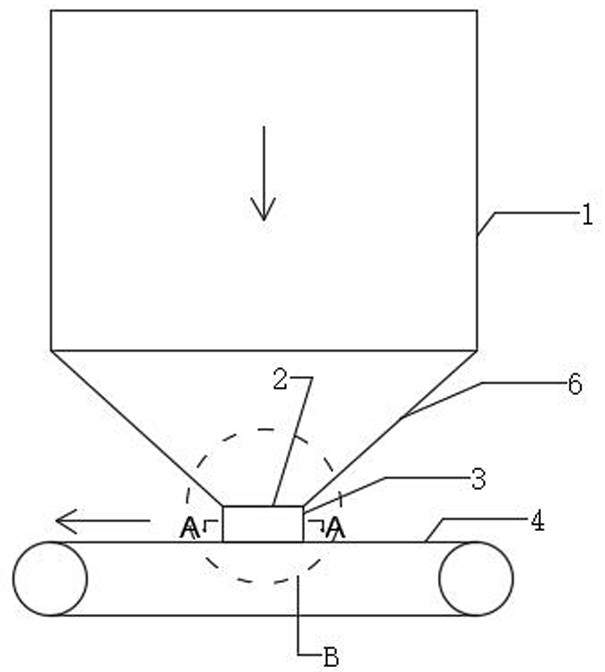

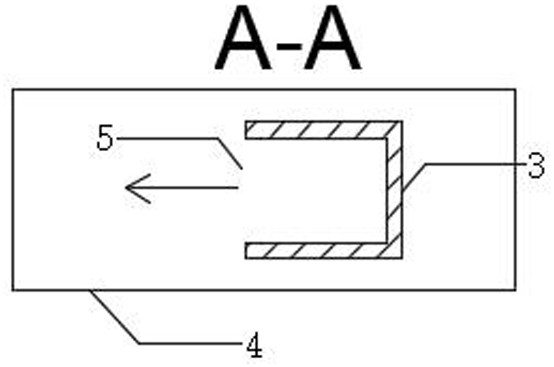

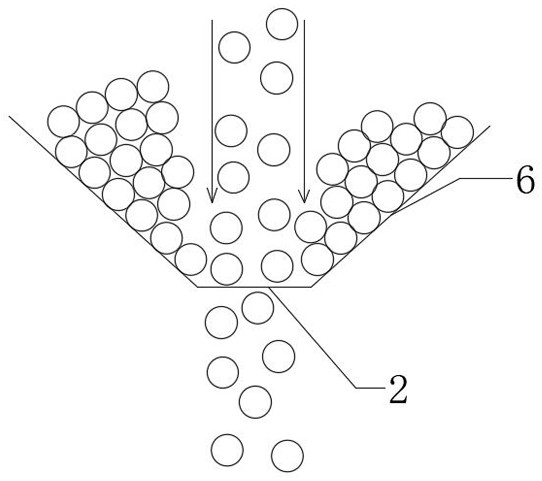

[0014] The technical solution of the present invention will be further described in detail in conjunction with the following drawings.

[0015] Such as Figure 1-Figure 4 As shown, an anti-clogging device for wet powder blanking, comprising: a powder funnel 1, the lower end of the powder funnel 1 is a conical funnel, and a transmission belt 4 is set at the lower end of the conical funnel outlet 2 at a distance of D. The stated D is 5 to 30 cm. According to the principle of powder mechanics, there is adhesion between powder particles. When the powder particles are small, they are easy to agglomerate due to the existence of adhesion. The adhesion between particles includes van der Waals force, electrostatic attraction, moisture capillary force, magnetic force, mechanical interlocking force, etc. Utilizing the adhesion between the wet powders, a part of the wet powders in the powder funnel 1 bonded to the inner wall 6 of the feeding device, under the action of the adhesion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com