A kind of preparation method and product of multi-component comfortable elastic antibacterial functional warp knitted fabric

A multi-component, comfortable technology, applied in warp knitting, dyeing, rayon manufacturing, etc., can solve the problems of fabric yield decline, spandex cannot be dyed, and poor washing resistance, etc., to achieve the effect of improving comfort and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

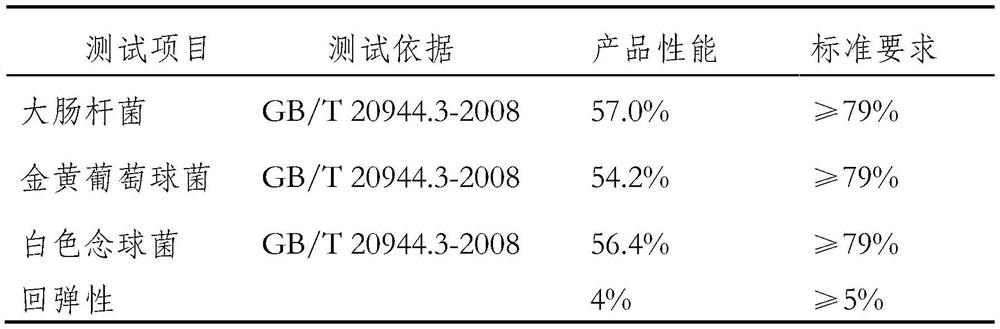

Embodiment 1

[0026] This embodiment provides a method for preparing a multi-component comfortable elastic antibacterial functional warp-knitted fabric:

[0027] 80 parts by weight of antibacterial polyester 75 / 72FDY and 20 parts by weight of ordinary polyester 75 / 144FDY are used as raw materials for the base yarn, the middle yarn is made of 50 / 48DTY PBT / PET bicomponent polyester fiber, and the top yarn is made of ordinary polyester 75 / 144DTY. Fabrics are made through weaving, shaping, finishing and dyeing, forming and sewing processes.

[0028] The setting speed is 30m / min, the setting temperature is 210°C, and the setting speed is 28m / min;

[0029] The finishing includes dyeing, drying, and water washing; wherein, the temperature of the dyeing is 130°C; wherein, the temperature of the drying is 160°C, and the washing is water washing with a softener, The softener is treated with tannin. The composition and parts by mass of the dyes used in the dyeing process are: 0.04 parts by mass of d...

Embodiment 2

[0035] 20 parts by weight of antibacterial polyester 75 / 72FDY and 80 parts by weight of ordinary polyester 75 / 144FDY are used as raw materials for the base yarn, the middle yarn is made of 50 / 48DTY PBT / PET bicomponent polyester fiber, and the top yarn is made of ordinary polyester 75 / 144DTY. The designed material is made through weaving, shaping, dyeing and finishing, and sewing processes.

[0036] The setting speed is 30m / min, the setting temperature is 210°C, and the setting speed is 28m / min;

[0037]The finishing includes dyeing, drying, and water washing; wherein, the temperature of the dyeing is 130°C; wherein, the temperature of the drying is 160°C, and the washing is water washing with a softener, The softener is treated with tannin. The composition and parts by mass of the dyes used in the dyeing process are: 0.04 parts by mass of disperse yellow, 0.0152 parts by mass of disperse red, 0.022 parts by mass of disperse blue, and 0.5 parts by mass of 98% glacial acetic ac...

Embodiment 3

[0043] 0 parts by weight of antibacterial polyester 75 / 72FDY and 100 parts by weight of ordinary polyester 75 / 144FDY are used as raw materials for bottom yarn, middle yarn is made of 50 / 48DTY polyester fiber, and top yarn is made of ordinary polyester 75 / 144DTY. , Sewing process made of the designed material.

[0044] The setting speed is 25-30m / min, the setting temperature is 210°C, and the setting speed is 28m / min;

[0045] The finishing includes dyeing, drying, and washing; wherein, the temperature of the dyeing is 100-130°C; wherein, the temperature of the drying is 160°C, and the washing is adding a softener Wash, softener is tannic acid treatment. The composition and parts by mass of the dyes used in the dyeing process are: 0.04 parts by mass of disperse yellow, 0.0152 parts by mass of disperse red, 0.022 parts by mass of disperse blue, and 0.5 parts by mass of 98% glacial acetic acid. The temperature control of the dyeing process is as follows: the initial temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com