Screw element for connecting pipes and a pipe connecting device

A technology for threaded components and connecting pipes, applied in the field of threaded components, can solve problems such as loosening or loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

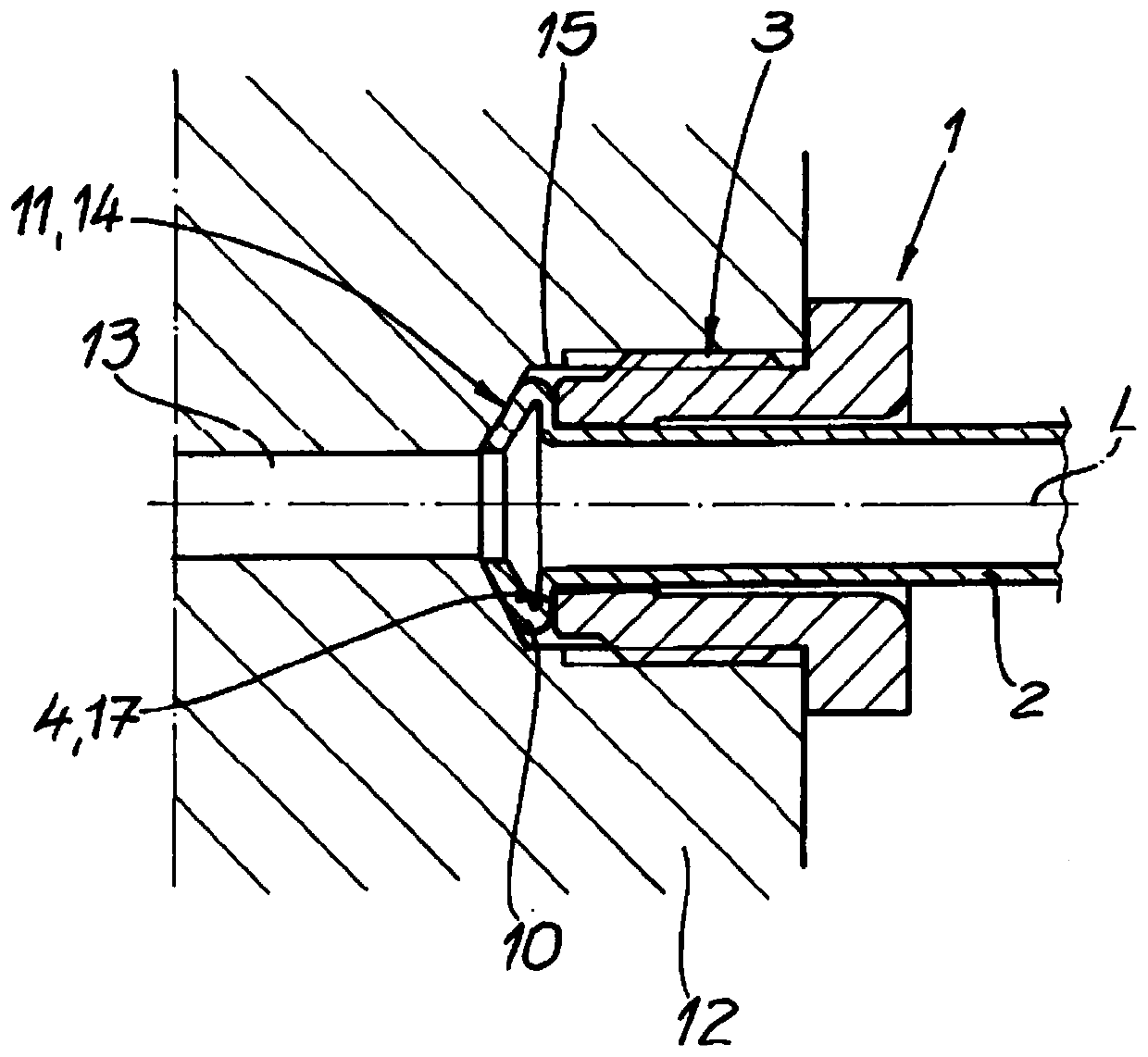

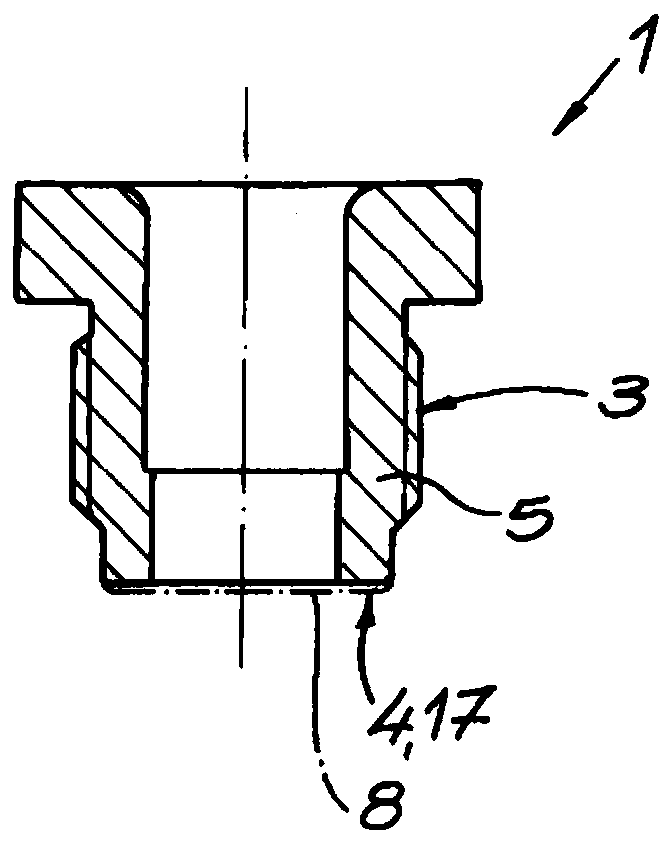

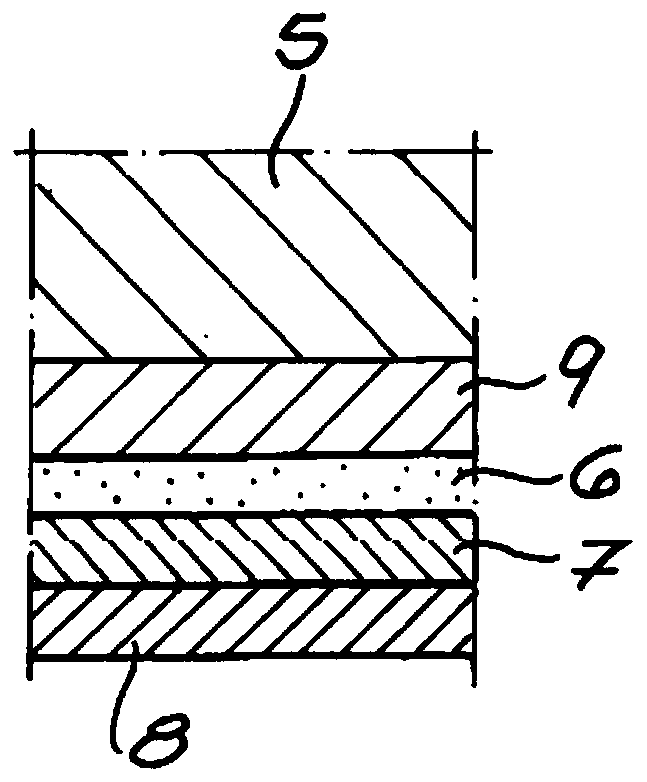

[0028] figure 1 Shown is a threaded element according to the disclosure, which is designed as a threaded joint 1 in a pipe connection device. In this exemplary embodiment, the pipe 2 passes through the threaded joint 1 in the axial direction and has a front element on one end which is designed as a flange 10 . Preferably, within the scope of the present disclosure, in this exemplary embodiment, this front element is a metal flange 10 , which is preferably integrally molded with the tube end of tube 2 . In this exemplary embodiment, the threaded joint 1 is screwed into a connecting element designed as a connecting block 12 . Advantageously, and in this exemplary embodiment, the connection block 12 here has an integrated second tube 13 . The threaded joint 1 presses the flange 10 such that the front sealing surface 11 of the flange 10 is pressed against the connection surface 14 of the connection block 12 . The threaded connection 1 is also screwed into the blind hole 15 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com