Heating pipe temperature control system and method for respiratory support device and respiratory support device

A technology for heating tube temperature and supporting equipment, which is applied in the direction of respirators, medical devices, and other medical devices, which can solve problems such as temperature limitations, insufficient control of tube temperature, and failure to consider the impact of ambient temperature, etc., to improve user comfort performance, to avoid the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

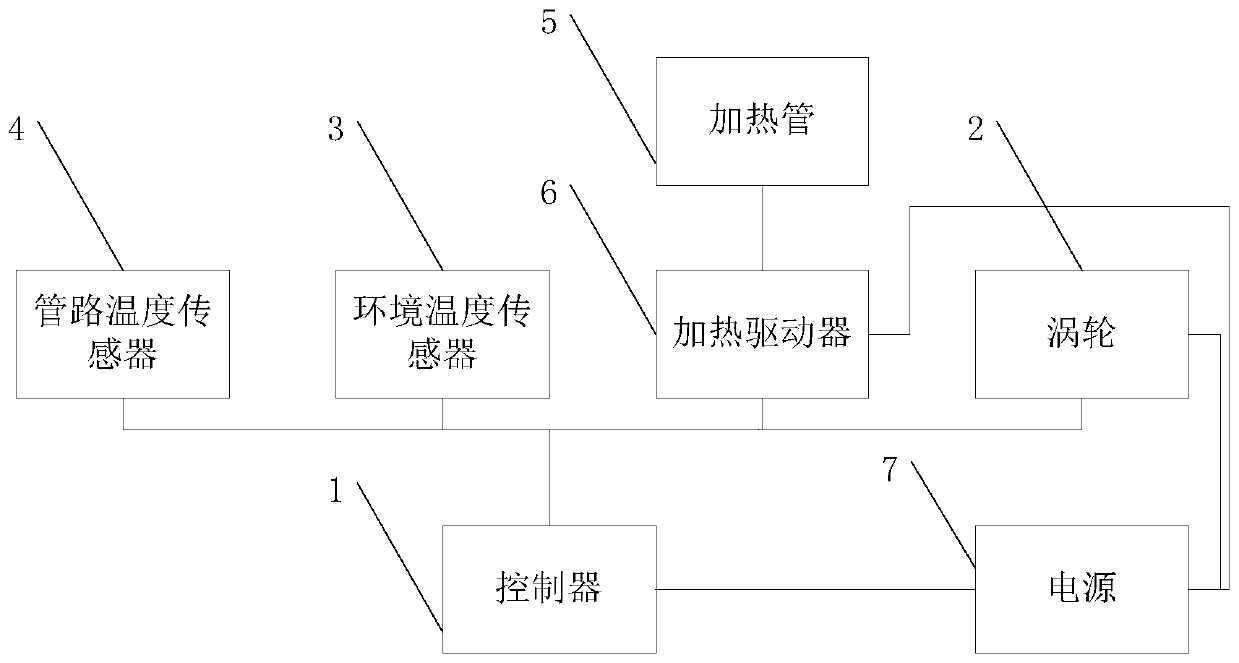

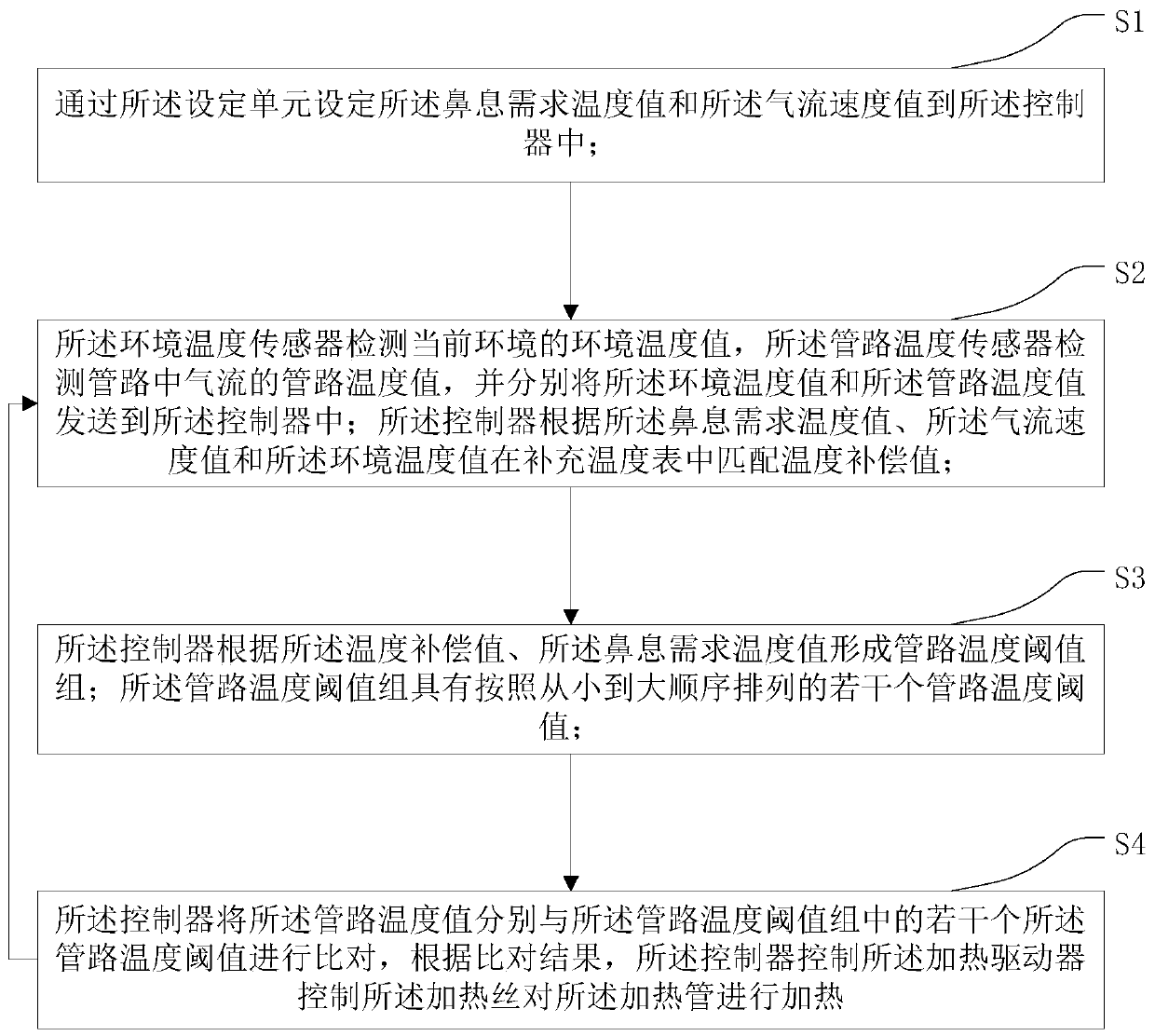

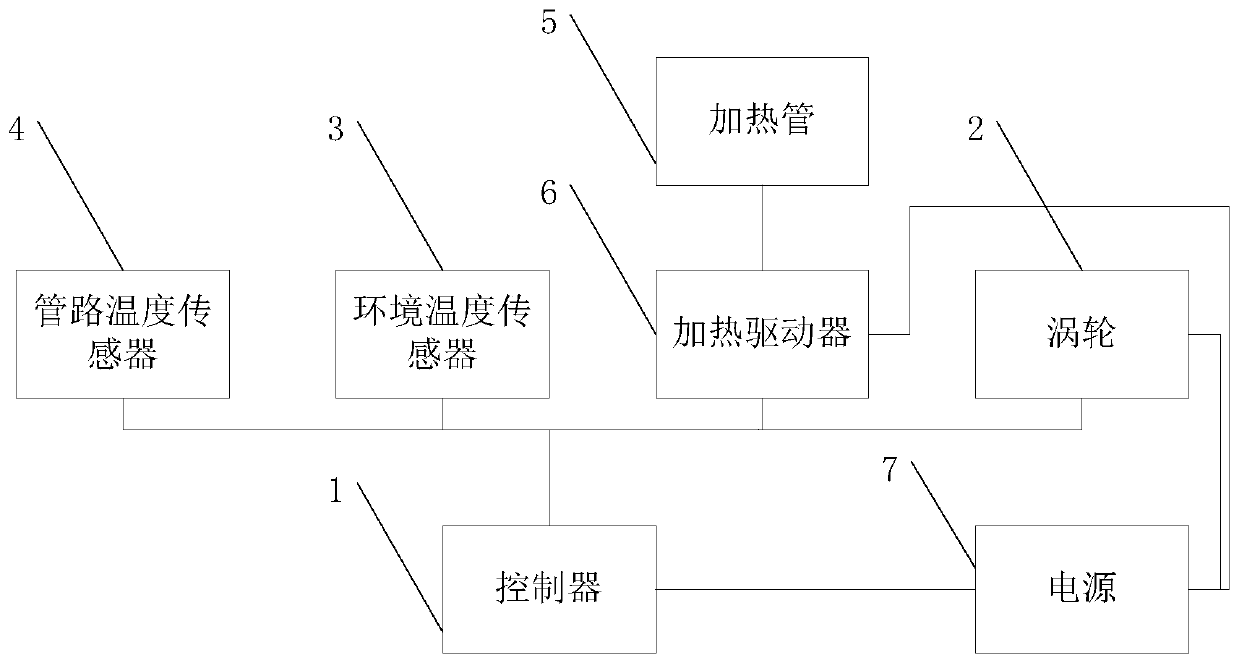

[0037]The present invention provides a heating tube temperature control system for respiratory support equipment, comprising: a controller 1, a turbine 2, an ambient temperature sensor 3, a pipeline temperature sensor 4, a heating tube 5, a heating driver 6 and a power supply 7; the turbine 2, The ambient temperature sensor 3, the pipeline temperature sensor 4 and the heating driver 6 are respectively connected to the controller 1; the power supply 7 is respectively the controller 1, the turbine 2, and the heating driver 6 power supply; the heating tube 5 has a heating wire, and the heating wire is connected to the heating driver 6; the pipeline temperature sensor 4 is installed at the end of the heating tube 5; the controller 1 includes a device The setting unit is used to set the temperature value of the snorting demand and the airflow velocity value of the turbine 2 outlet. Specifically, the controller 1 is a processor (MCU (Microcontroller Unit, micro control unit) or CPU ...

Embodiment 2

[0059] Set the snorting demand temperature value to 33°C, the airflow velocity value to 40L / Min, and the supplementary temperature table is the following table:

[0060]

[0061]

[0062] When the machine is turned on for treatment, it first detects the current ambient temperature value, and the controller 1 obtains the temperature compensation value Z°C of the nasal oxygen tube part according to the above table, and the ambient temperature value is also collected and monitored in real time. Afterwards, the temperature at the end of the pipeline is detected in real time, and the control accuracy k is set to 2, and the total number of data a of the pipeline temperature threshold group is set to 5, and judgment is made based on this: 1. When the When the end temperature of the pipeline temperature value is less than (33+Z-1) ° C, the heating tube 5 is heated rapidly with a heating power value of 92% as the operating power; 2. When the pipeline temperature value is less than...

Embodiment 3

[0064] A respiratory support device, comprising the temperature control system of the heating tube of the respiratory support device.

[0065] The respiratory support equipment is mainly composed of the main body of the humidification oxygen therapy instrument, a humidification water box, a heating plate and an external pipeline. The water box and the heating plate constitute the main structure of the humidification part, and the external pipeline is mainly a heating pipeline and a nasal oxygen tube. composition.

[0066]After the air and oxygen are mixed, they enter the water box after passing through the turbine 2, and the heating plate continues to heat, taking away part of the water vapor, and then supplying the patient after being heated and kept warm by the heating pipeline. This invention mainly introduces the method of controlling the heating temperature of the heating pipeline through empirical data and monitoring the temperature at the end of the pipeline and the amb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com