Catalyst with hydrogen storage performance, preparation method and application thereof

A catalyst and performance technology, which is applied in the field of catalysts with hydrogen storage performance and its preparation, can solve problems such as easy side reactions and complex reactions, and achieve the effect of low requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

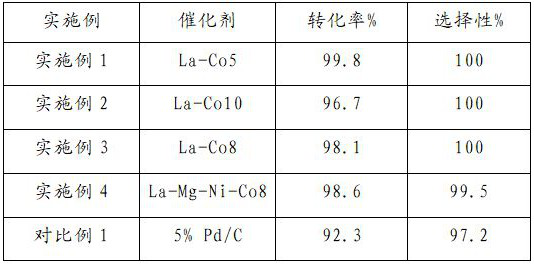

Embodiment 1

[0018] Embodiment 1: the preparation method of the catalyst with hydrogen storage performance, including the following steps: first, the metal hydrogen storage material LaNi 5 Mechanically grind into 200-600 mesh alloy powder, and then mix the metal boride Co-B and metal hydrogen storage material powder at a ratio of 5:1. After mixing, the sample is placed in a mechanical ball mill, and the ball milling time is set to 3-48h. The ball milling speed is 200 -600r / min, the ratio of ball to material is 6:1; after the ball milling, the metal with catalytic activity is attached to the surface of the hydrogen storage alloy in an amorphous form, which is marked as catalyst La-Co5.

[0019] Among them, the preparation method of Co-B is: NaBH 4 Prepared as 0.01-10 mol / L solution, soluble metal salt Co(NO 3 ) 2 Dissolve in deionized water to prepare a solution of 0.05-5mol / L, at room temperature, under magnetic stirring, NaBH 4 It is slowly dropped into the soluble metal salt solution...

Embodiment 2

[0020] Example 2, the only difference between Example 2 and Example 1 is that the metal boride Co-B and the metal hydrogen storage material powder are labeled as catalyst La-Co10 at a ratio of 10:1.

Embodiment 3

[0021] Example 3: The difference between Example 3 and Example 1 is only that the metal boride Co-B and the metal hydrogen storage material powder are 8:1, marked as catalyst La-Co8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com