Deformable wing

A wing and wing section technology, applied in the direction of wing adjustment, etc., can solve the problems of adverse effects of wing aerodynamic efficiency, corrugated plate deformation skin surface discontinuity, large drag coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

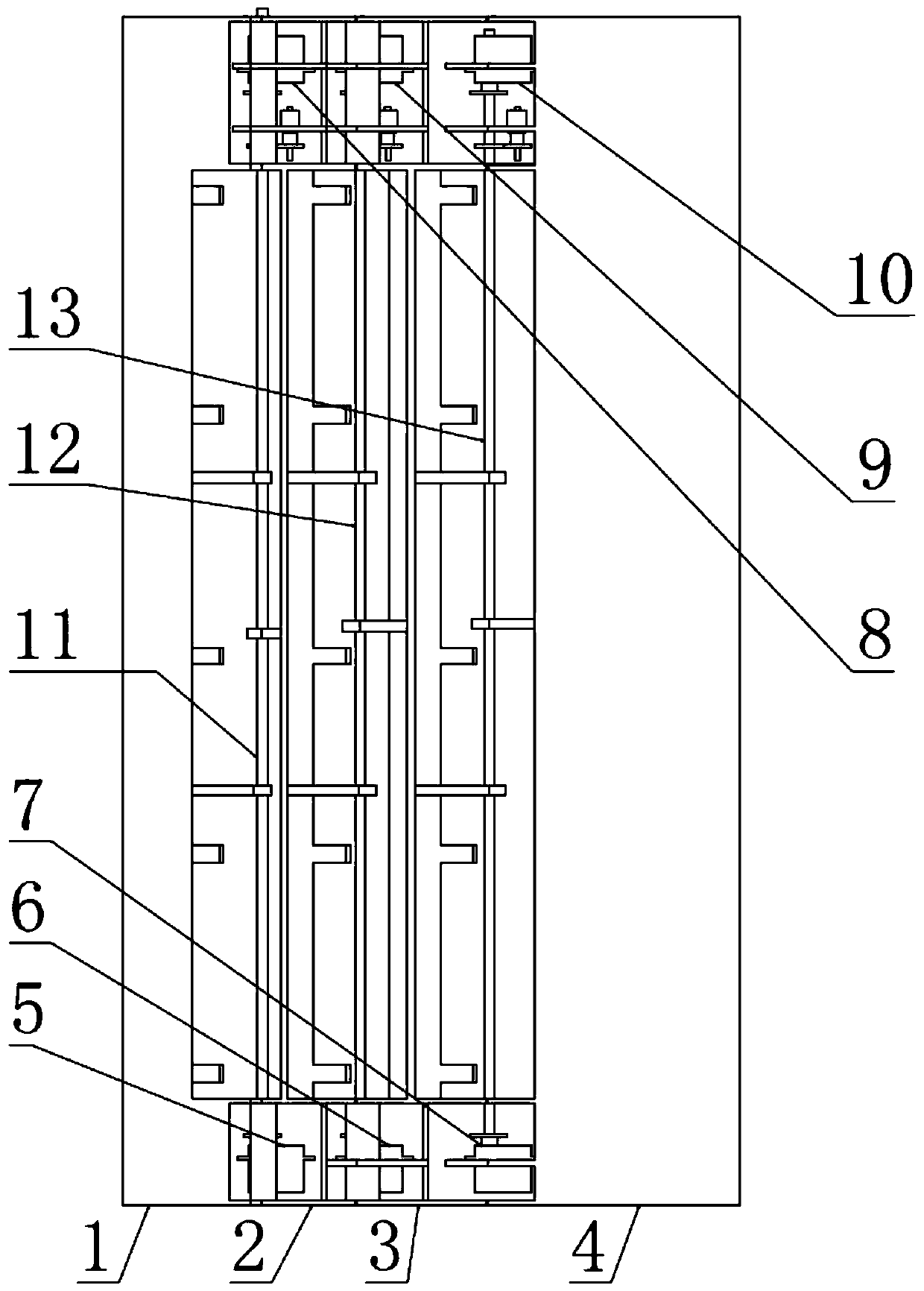

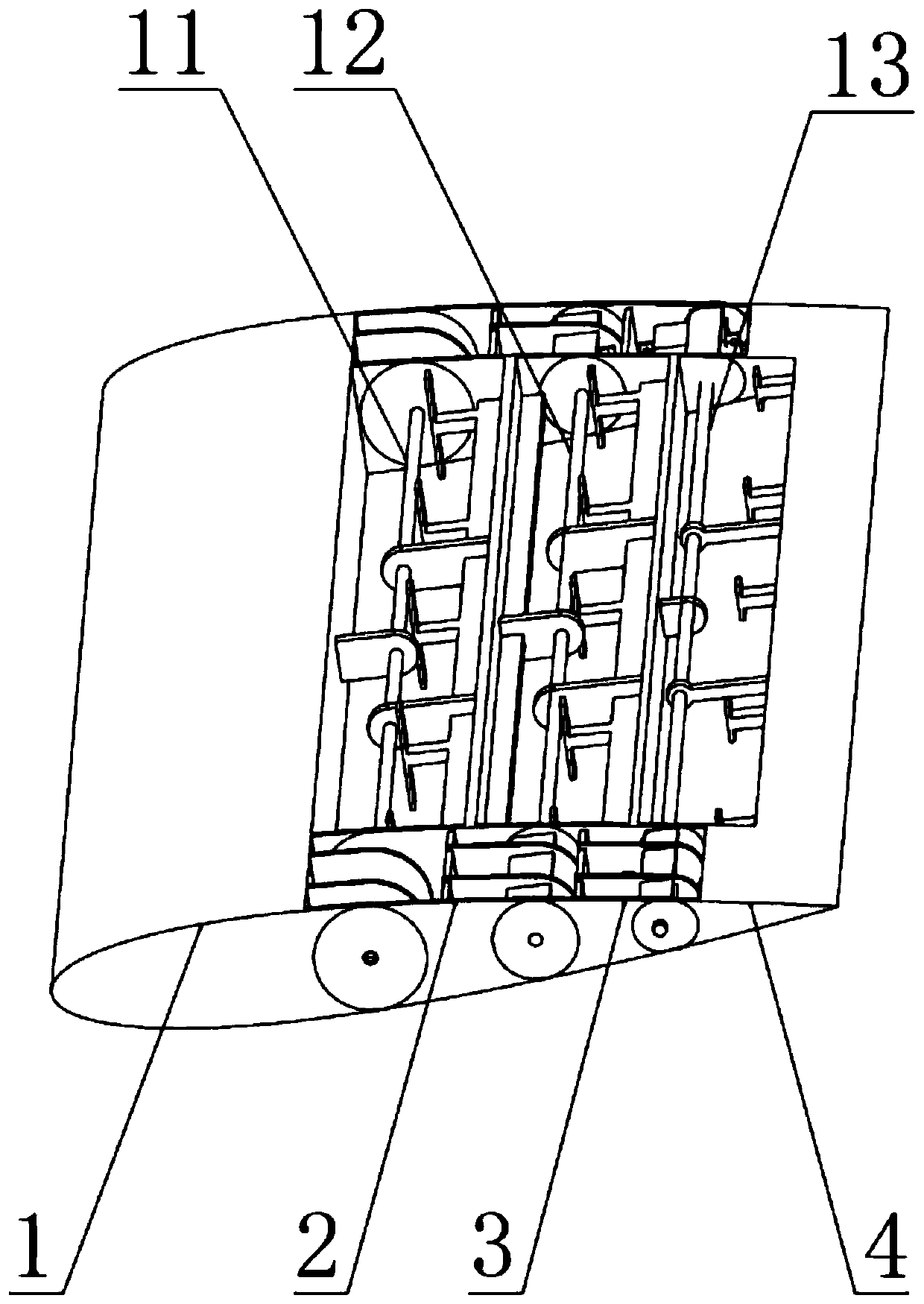

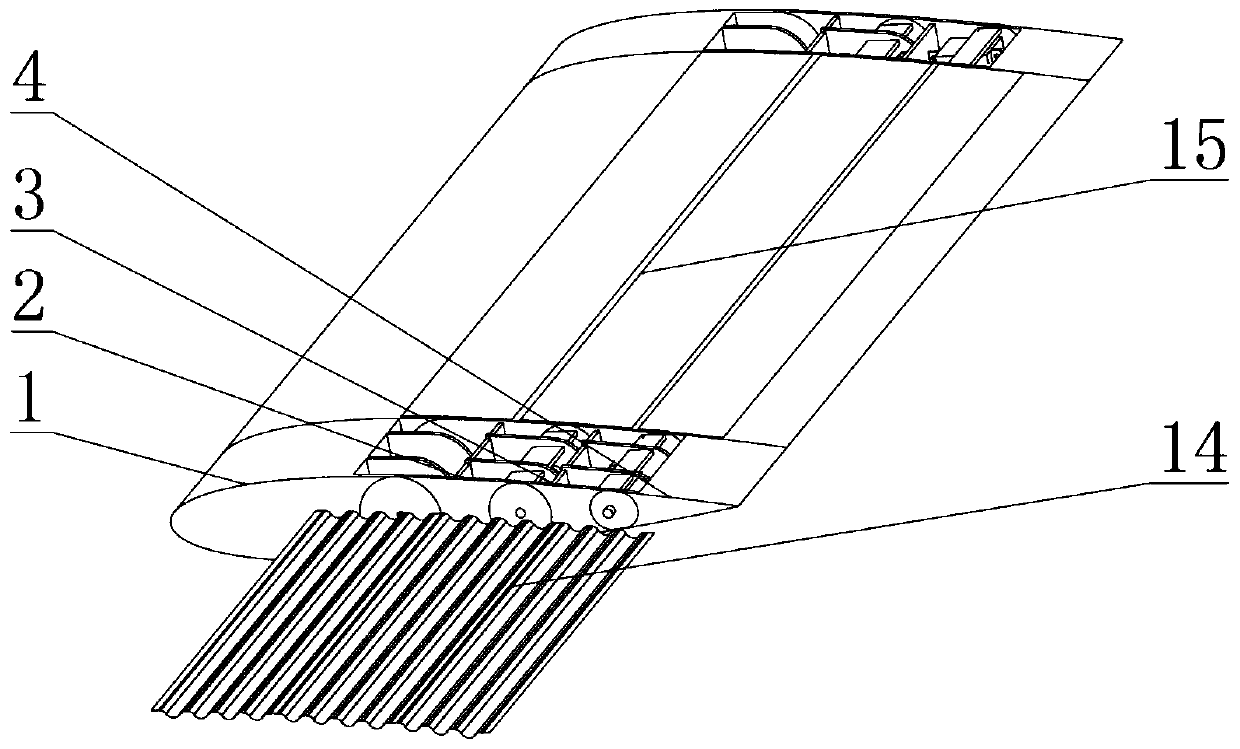

[0035] In order to solve the above-mentioned technical problems of the prior art, the inventor provides a deformed wing device, which includes four first to fourth wing sections 1, 2, 3, 4 made of laminates, the first to the fourth Six servos 5, 6, 7, 8, 9, 10, the outer diameter is The first to third shafts 11, 12, 13 made of aluminum, corrugated structure skin 14, rubber film skin 15, such as Figure 1-3 shown.

[0036] Such as Figure 4 As shown, the first wing section 1 is a fixed wing section, including a D-box 1.1 that supports the leading edge structure of the airfoil and improves the torsional rigidity, and eight lugs 1.2. Each lug 1.2 is marked with round hole. Such as Figure 5 As shown, the second wing section 2 is a movable section, including; T-beam structure 2.1, which is used to improve the bending stiffness of the wing; ten lugs 2.2, each of which has a The circular holes; 5 vertical bar-shaped supports 2.3 for connecting the corrugated skin to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com