Bottle cap conveying and sterilizing device

A technology of sterilization device and bottle cap, which is applied in the direction of synchronization device, packaging, bottling machine, etc., can solve the problems of short sterilization period, poor sterilization effect, and inability to uniformly sterilize bottle caps, and achieve uniform sterilization and good sterilization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

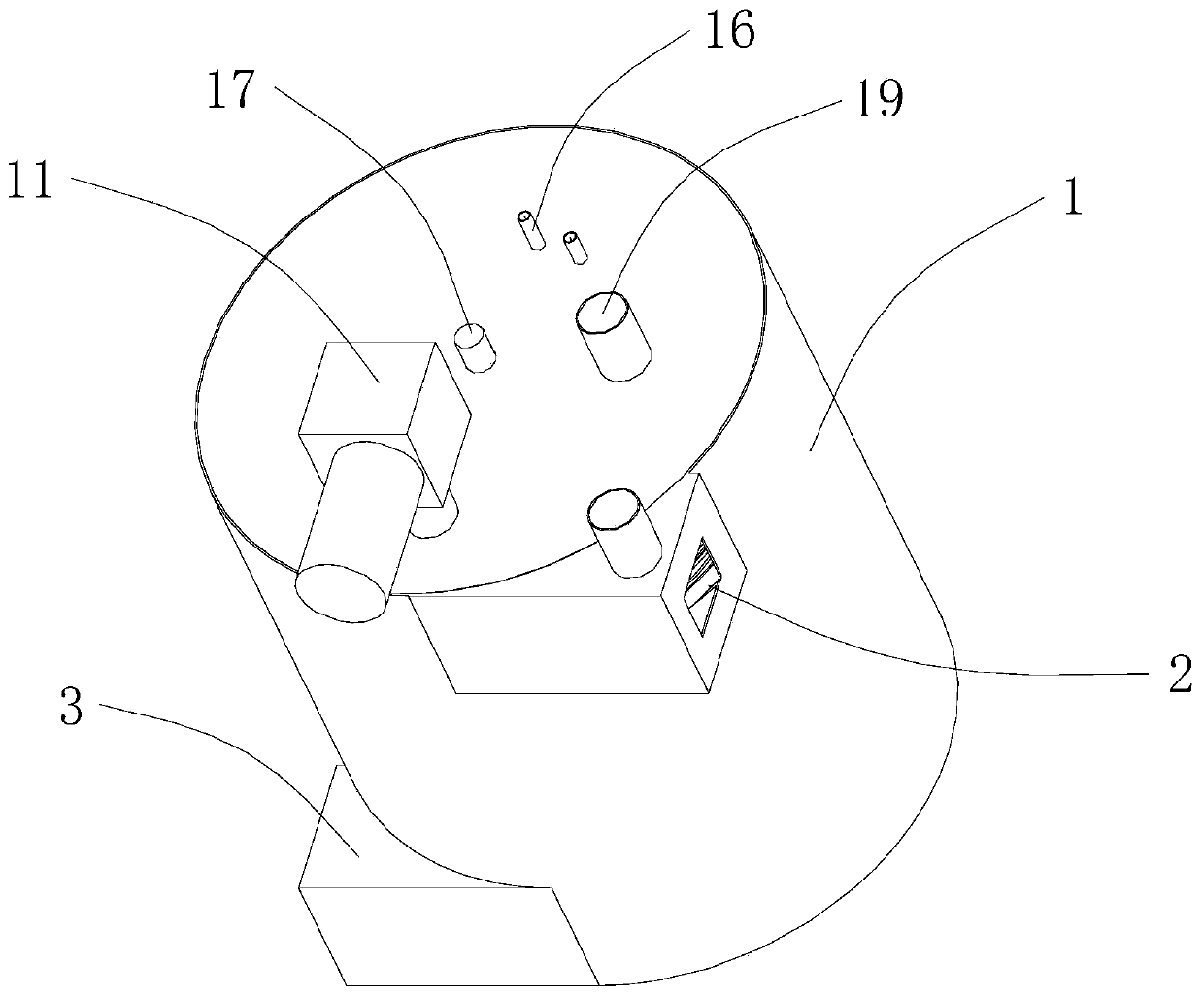

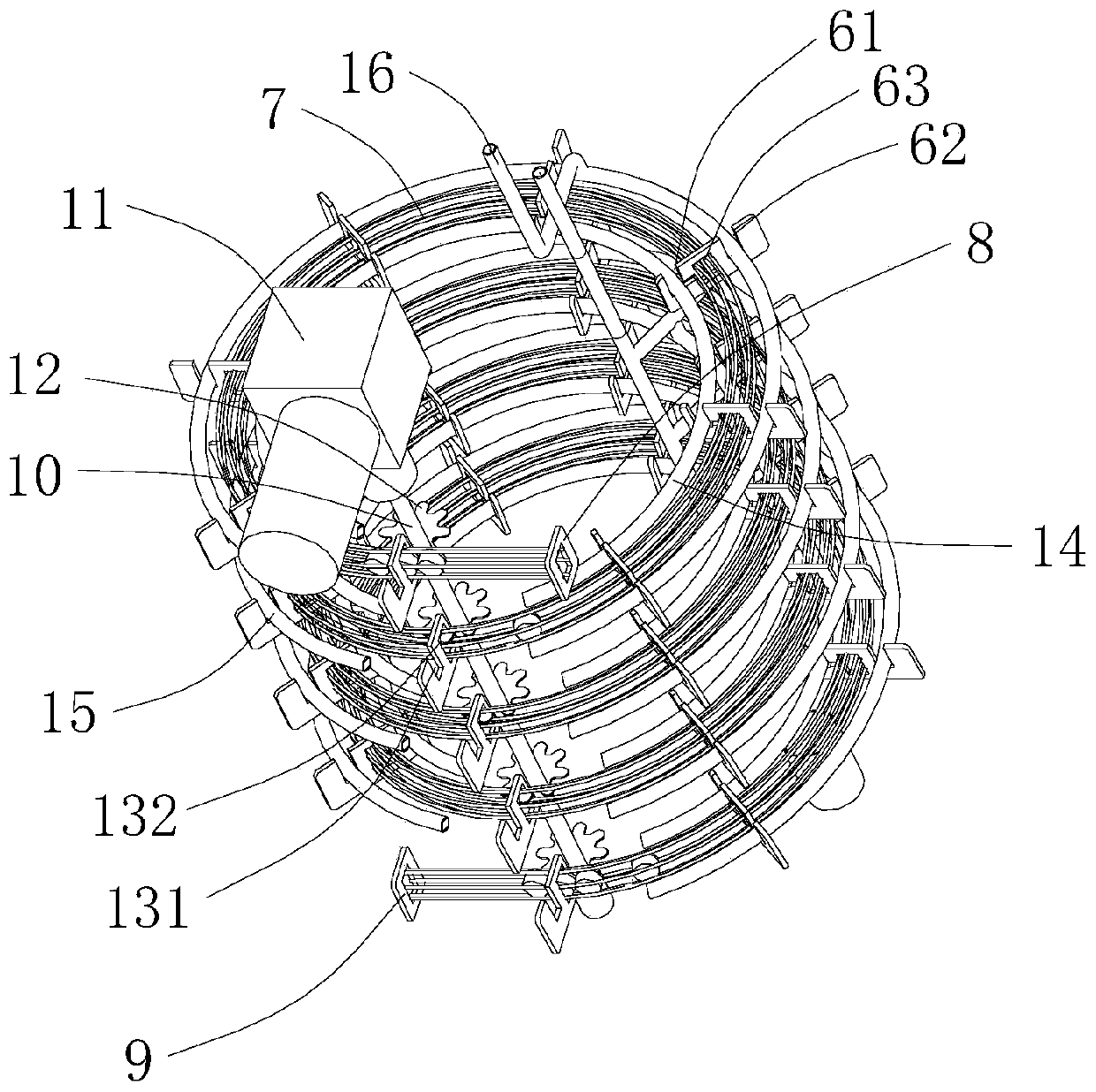

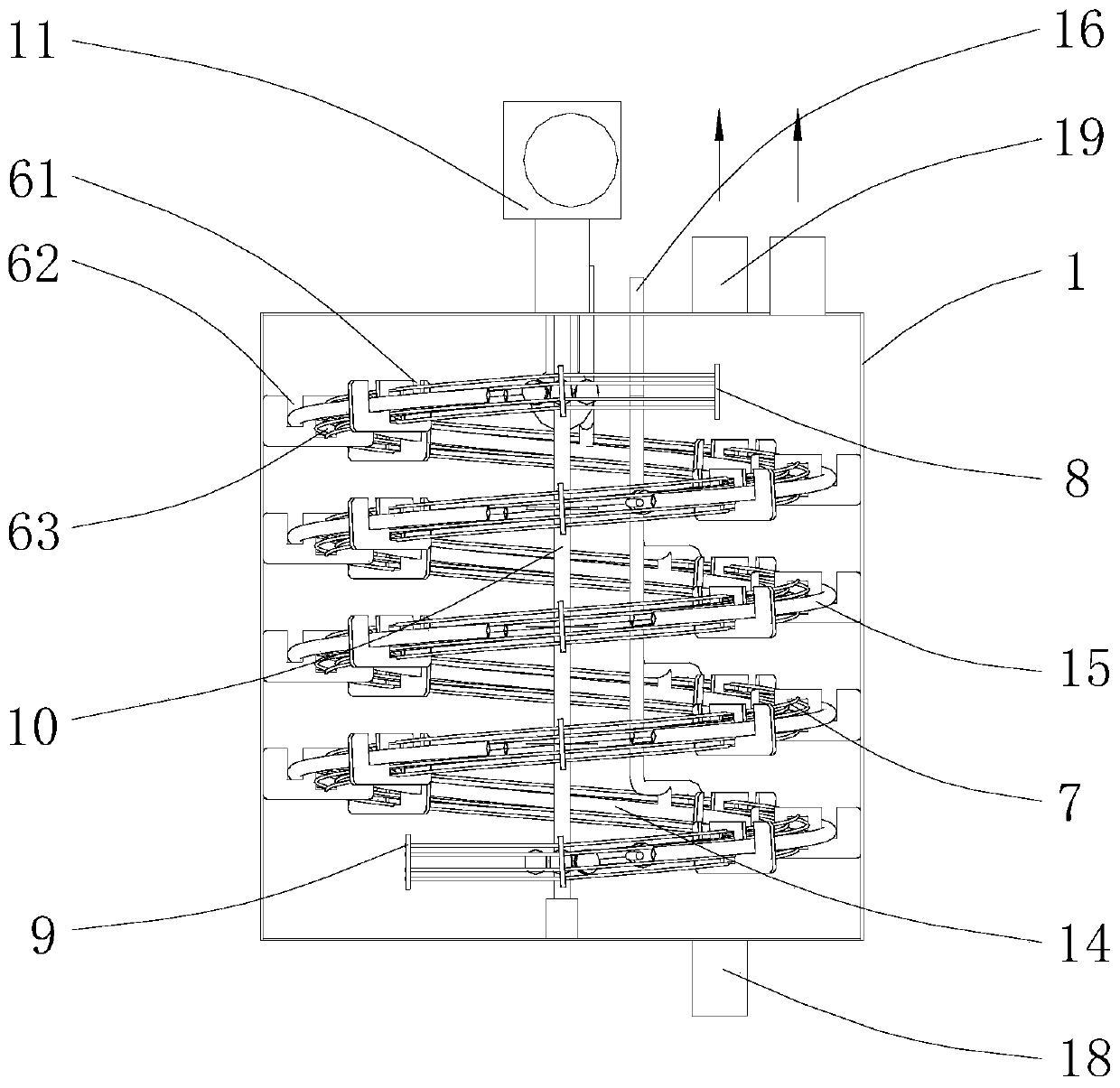

[0029] see Figure 1-9 As shown, the above-mentioned bottle cap conveying and sterilizing device includes a housing 1 with a hollow inner cavity, a cap conveying channel arranged in the housing 1 along the spiral direction, and a channel for driving the bottle cap in the housing 1. The driving mechanism that moves along the feeding direction in the cap conveying channel, the inner helical pipeline that is arranged in the shell 1 and is wound on the inner side of the cap conveying channel, and the spiral in the shell 1 that is wound on the outside of the cap conveying channel The outer spiral pipeline, the feed interface 2 opened on the shell 1 and communicated with the feed end of the cover conveying channel, the discharge interface 3 opened on the shell 1 and communicated with the discharge end of the cover conveying channel; The outer side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com