High-speed railway expansive rock soil deep cutting structure and construction method thereof

A technology of high-speed railways and expansive rocks, applied in infrastructure engineering, roads, buildings, etc., to achieve the effects of controllable stability, favorable promotion and application, and small arching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

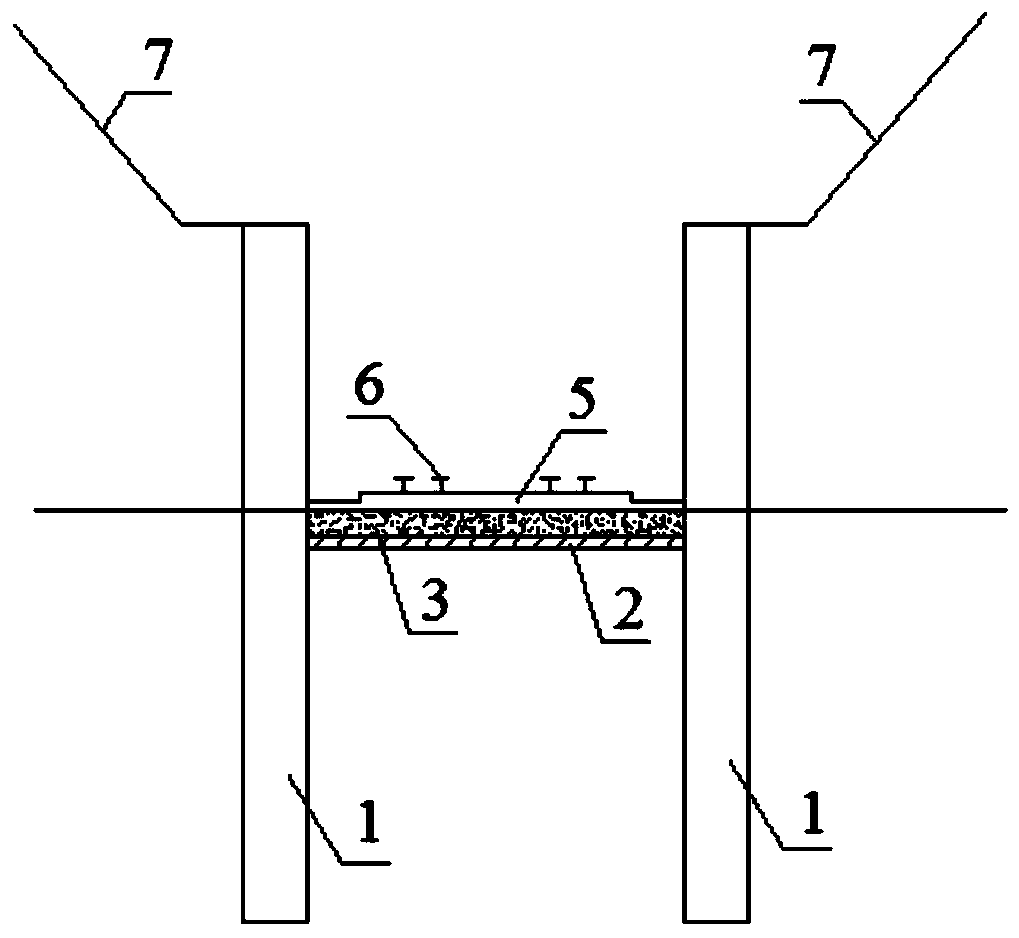

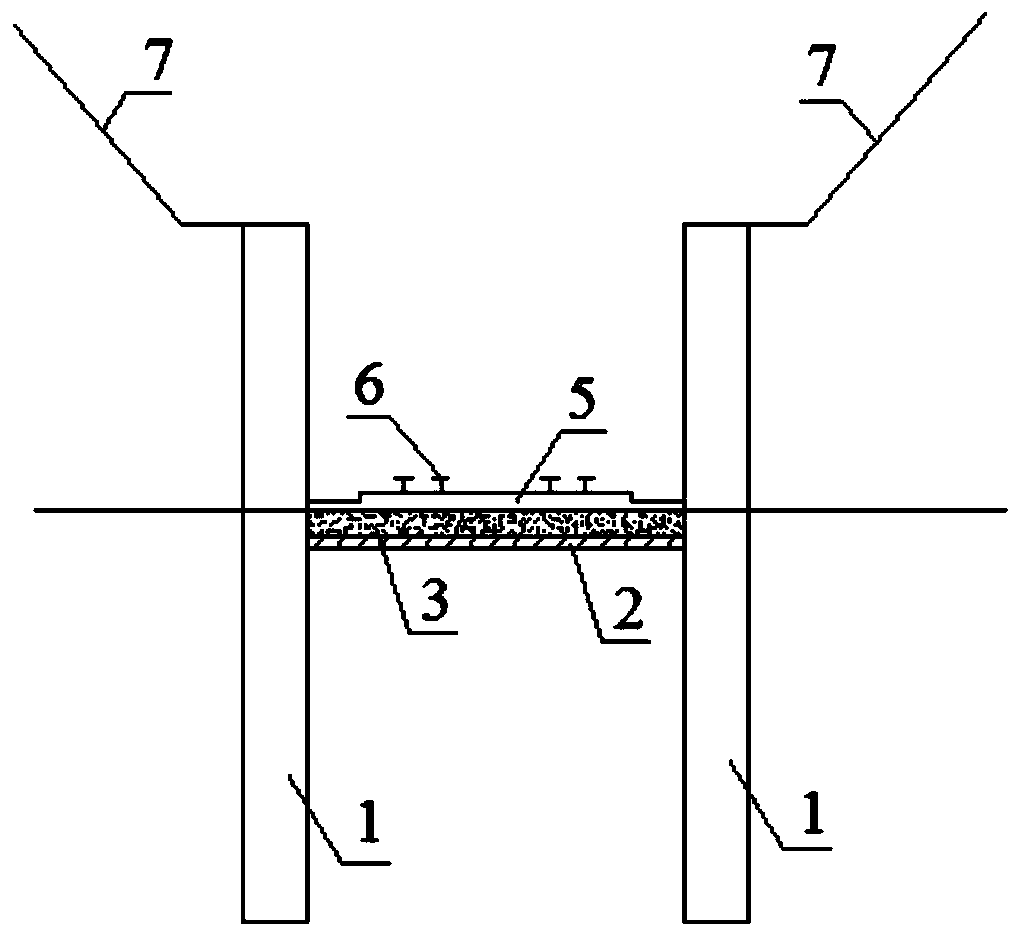

[0045] Such as Figure 1-2 Shown, a kind of high-speed railway expansive rock-soil deep cutting structure of the present invention comprises:

[0046]A plurality of reinforcement support piles 1 are divided into two rows and arranged symmetrically at the foot of the deep road cutting slope. The reinforcement support piles 1 in each row are arranged at intervals, and the distance between two adjacent reinforcement support piles 1 in each row of the reinforcement support piles 1 is 5m-7m:

[0047] The support beam 3 is arranged on the foundation between the two symmetrically arranged reinforced support piles 1, and the bottom of the support beam 3 is provided with water holes at intervals, and the water holes are arranged in an upper concave shape. The section of the water hole is semicircular, rectangular, triangular or trapezoidal, and the width of the water hole is 0.1m-0.2m;

[0048] The buffer layer 2 is arranged on the foundation at the bottom of the support beam 3, and ...

Embodiment 2

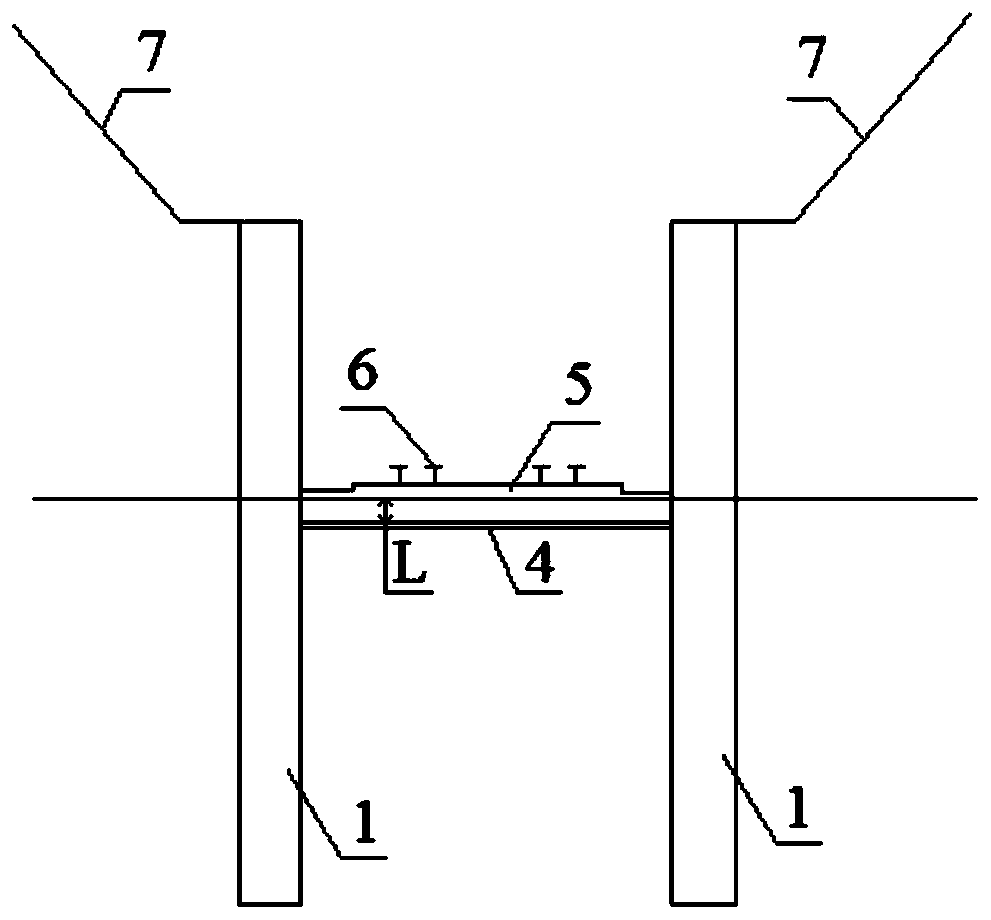

[0054] Such as Figure 1-2 As shown, a kind of construction method of high-speed railway expansive rock-soil deep cutting structure as described in embodiment 1 of the present invention, comprises the following steps:

[0055] A. Excavate the expansive rock-soil slope layer by layer from top to bottom, and reinforce and protect the excavated slope 7 layer by layer until the top elevation of the reinforced support pile 1 is set;

[0056] B. The pile well of the reinforced support pile 1 is constructed at intervals, at the position where the support beam 3 and the bearing plate 5 are arranged, the steel bars of the support beam 3 of different lengths are pre-embedded outwards through the pile well and the 5 steel bars of the bearing plate, the length is 1m-3m;

[0057] C, setting the reinforced support pile 1 reinforcement cage, the reinforcement support pile 1 reinforcement cage is respectively fixedly connected with the 3 reinforcement bars of the support beam and the 5 reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com