A detachable recoverable anchor rod and its construction method

A construction method and bolt technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of single fixed end face of bolt, low recovery rate, and difficulty in ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

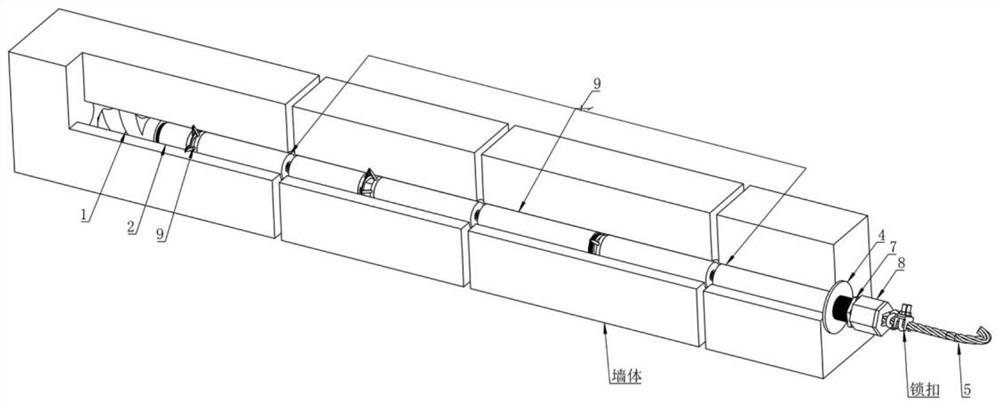

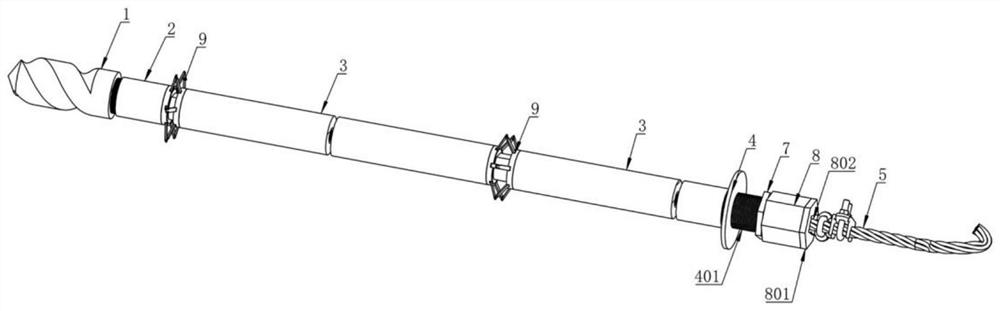

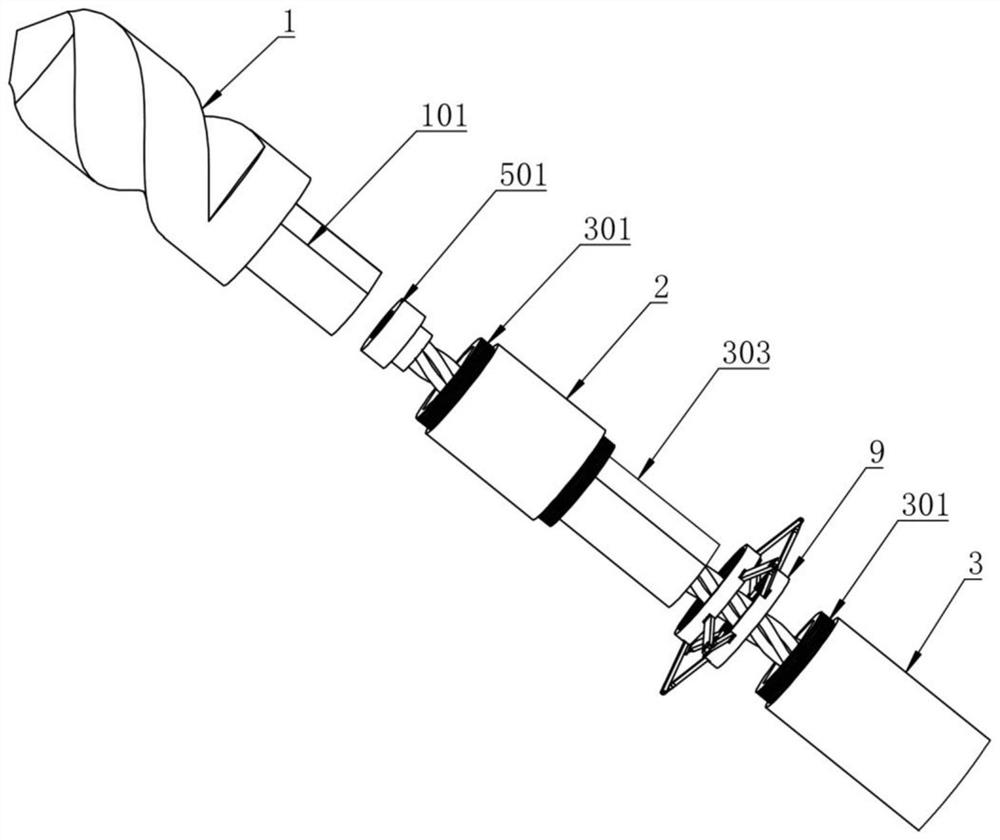

[0040] Specific implementation mode one: combine Figure 1-8 As shown, a detachable recoverable anchor and its construction method are characterized in that: it includes long anchor construction and short anchor construction, and it is characterized in that it includes an anchor head 1, a drill bit section 2, a drill pipe section 3, and a fixed plate 4. Steel wire rope 5, screw rod 6, nut 7, tension sleeve 8 and zipper expansion fixing device 9; the front end of the anchor head 1 is a twist drill; the rear end of the anchor head 1 is provided with a key block 101; the anchor head 1 is provided with a key block 101; The head 1 is arranged at the front end of the drill bit section 2; the drill bit section 2 and the drill bit section 2, the drill bit section 2 and the drill pipe section 3, and the drill pipe section 3 and the drill pipe section 3 are respectively connected by a zipper expansion fixing device 9; The left end of the steel wire rope 5 is fixedly provided with a stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com