Construction method for treating ultra-deep plain concrete diaphragm wall guide hole joints

A joint treatment and construction method technology, which is applied to sheet pile walls, foundation structure engineering, foundation structure tests, etc., can solve problems such as high cost, broken pipes in lock pipes or joint boxes, and long construction period of plain land connection walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

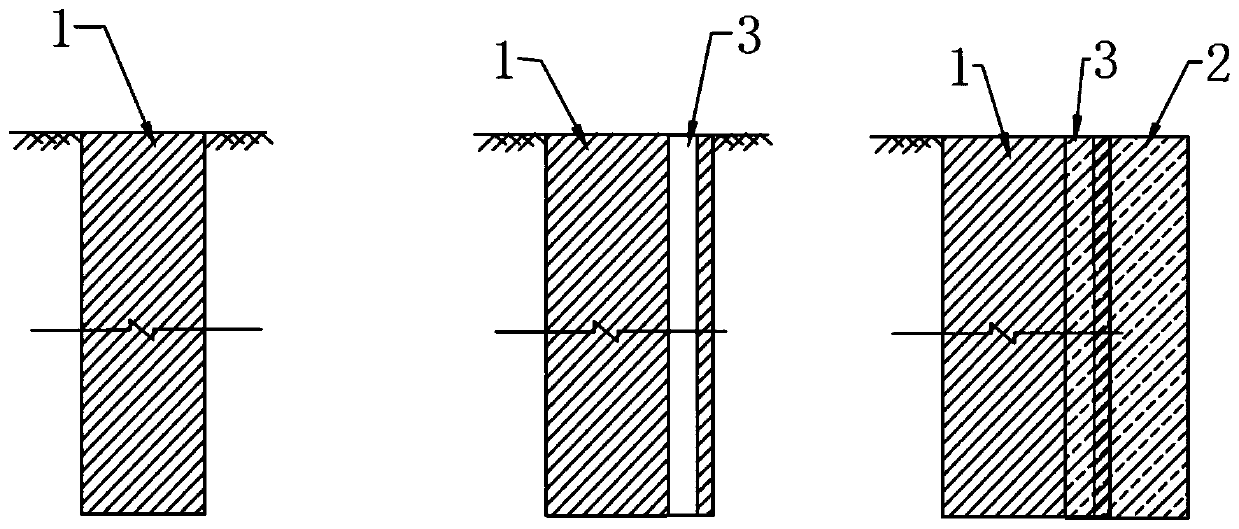

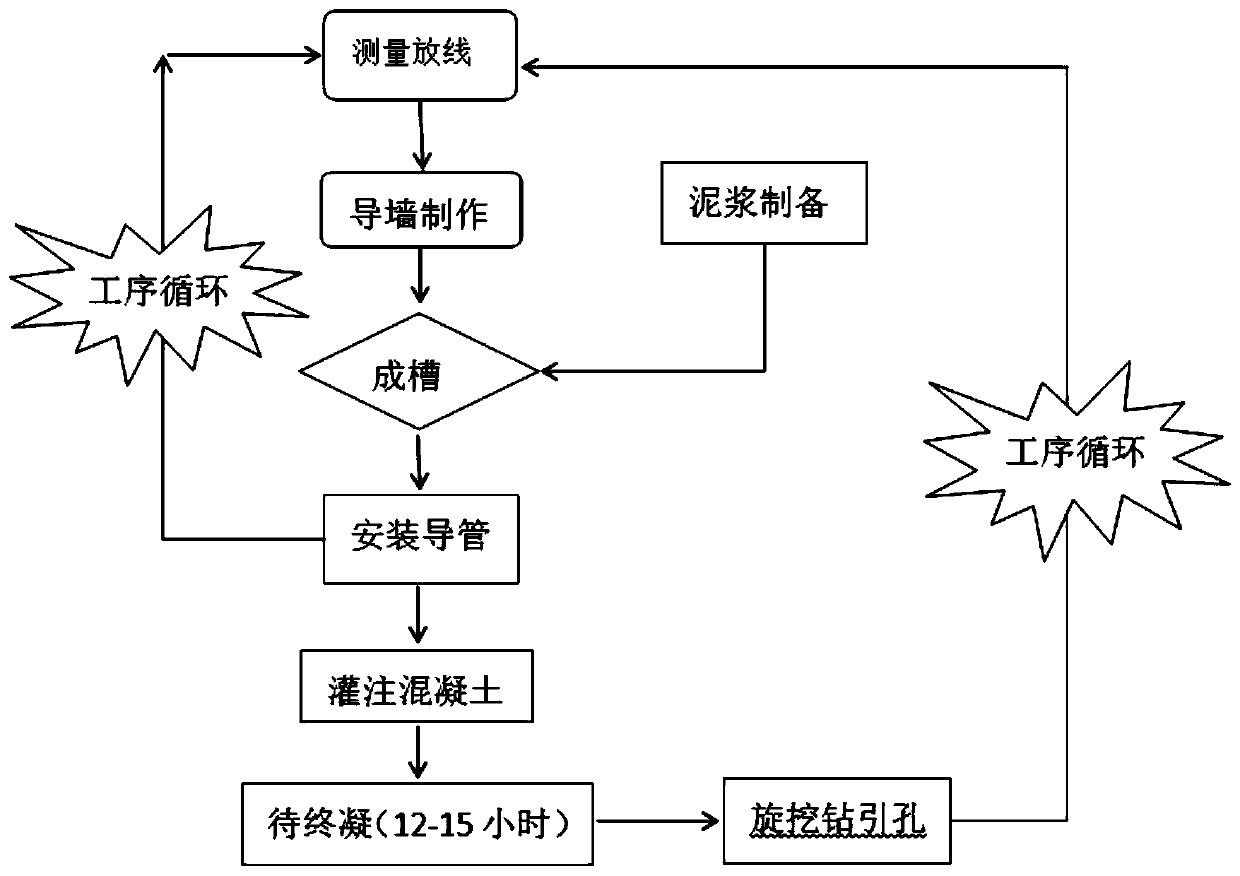

[0044] This embodiment discloses a construction method for treating the joints of the lead holes of the ultra-deep plain ground connection wall, the method is as follows:

[0045] S1. Measure and set out the line, carry out plane measurement and elevation measurement, and determine the reference wire and elevation control point;

[0046] S2, guide wall production, use the total station to release the axis of the bottom wall and the position of the guide wall, manually clear the bottom after the guide wall is excavated, pour concrete after the guide wall molding is completed, and remove the formwork after the strength reaches 70%;

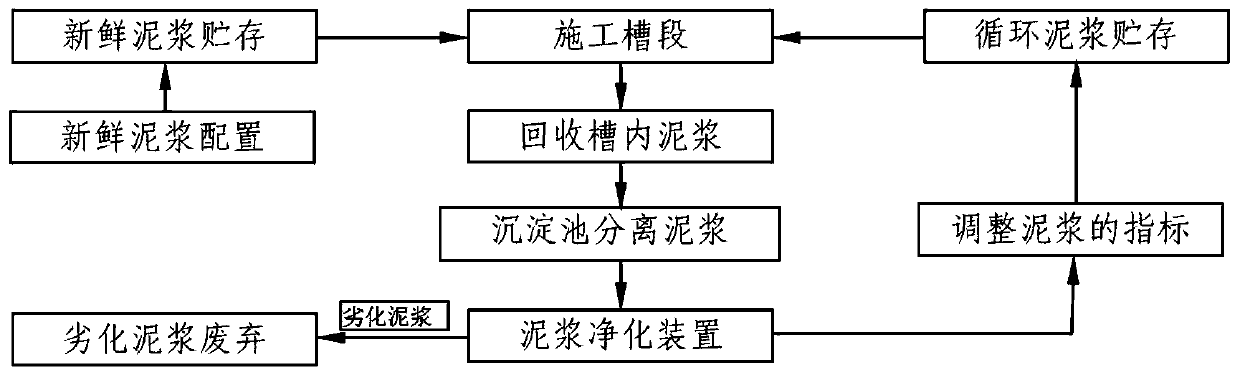

[0047] S3. Groove construction, pouring concrete into the groove, and performing groove section detection and cleaning the bottom and wall;

[0048] S4. Install the conduit, insert the conduit to an elevation of 300-800mm from the bottom of the tank, and the concrete storage in the conduit collecting hopper ensures the initial filling volume;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com