Bypass-air-return top coal caving mining system of extra-large-dip medium-thickness coal seam

A technology of caving top-coal in thick coal seams, applied in the mining system of top-coal caving in medium-thick coal seams with large inclination of bypass return air, can solve problems such as large safety hazards, poor construction management, difficult mechanized mining, etc., and achieve high mining efficiency , the effect of solving security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description and drawings fully demonstrate the specific embodiments of the present invention so that those skilled in the art can practice them. Other implementations may include structural, logical, electrical, process, and other changes. The examples only represent possible changes. Unless explicitly required, individual components and functions are optional, and the order of operations can be changed. Parts and features of some embodiments may be included in or substituted for parts and features of other embodiments.

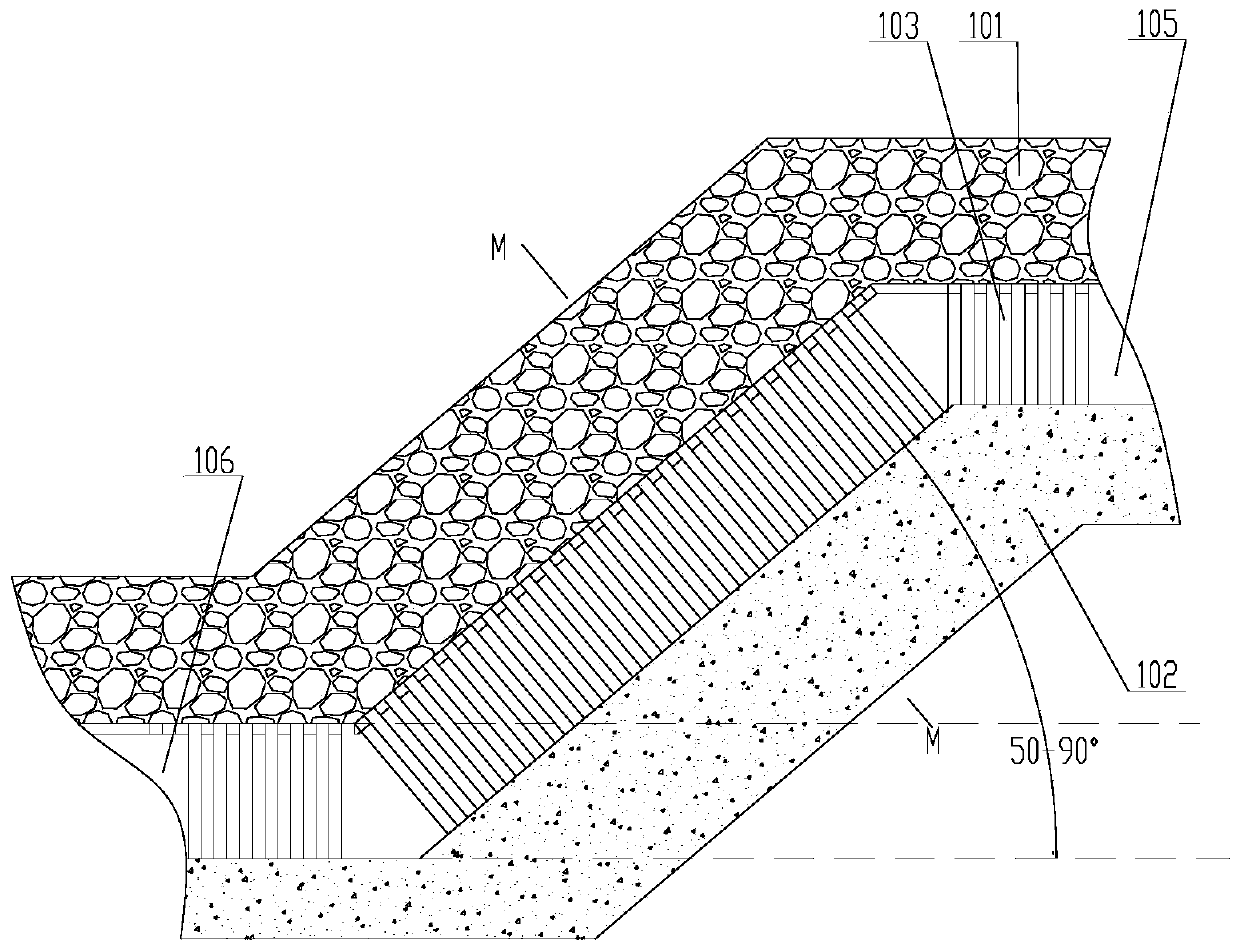

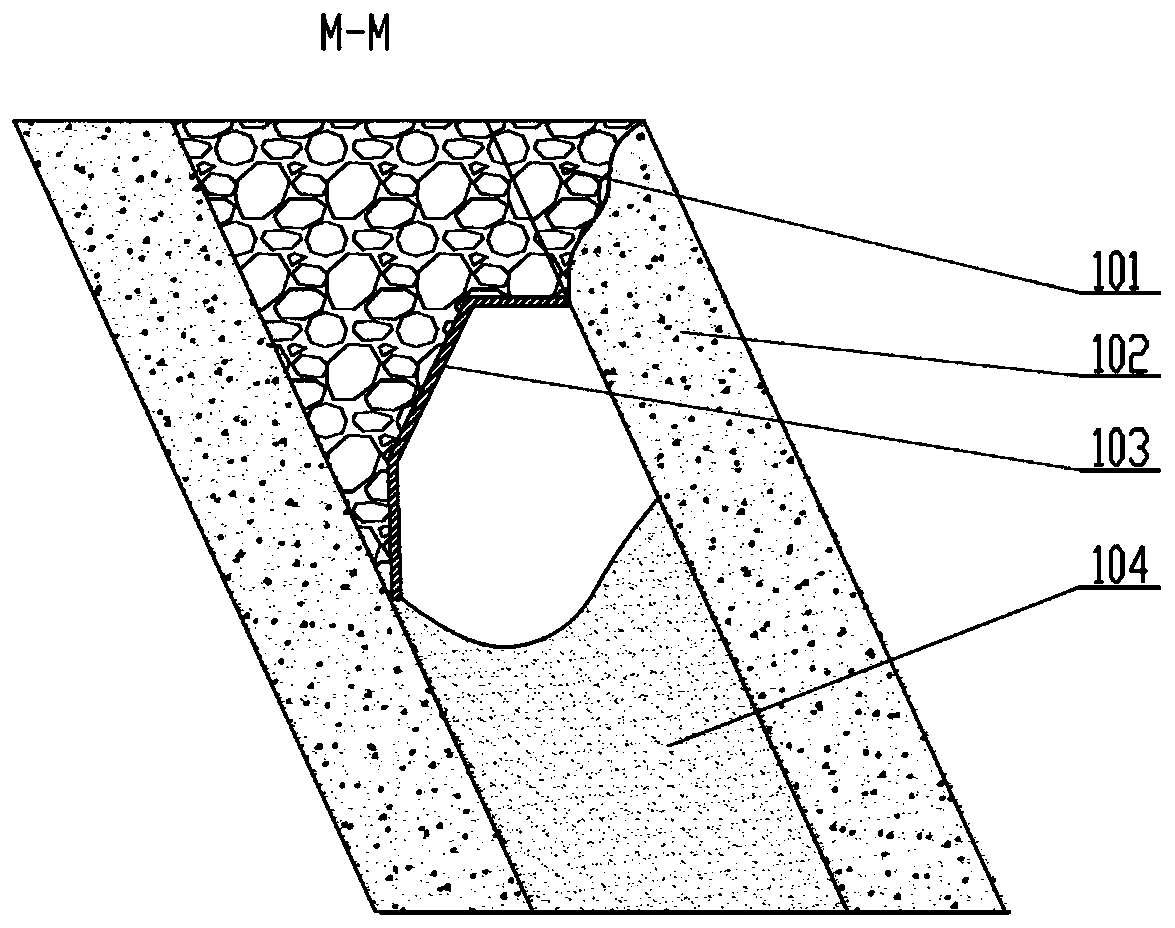

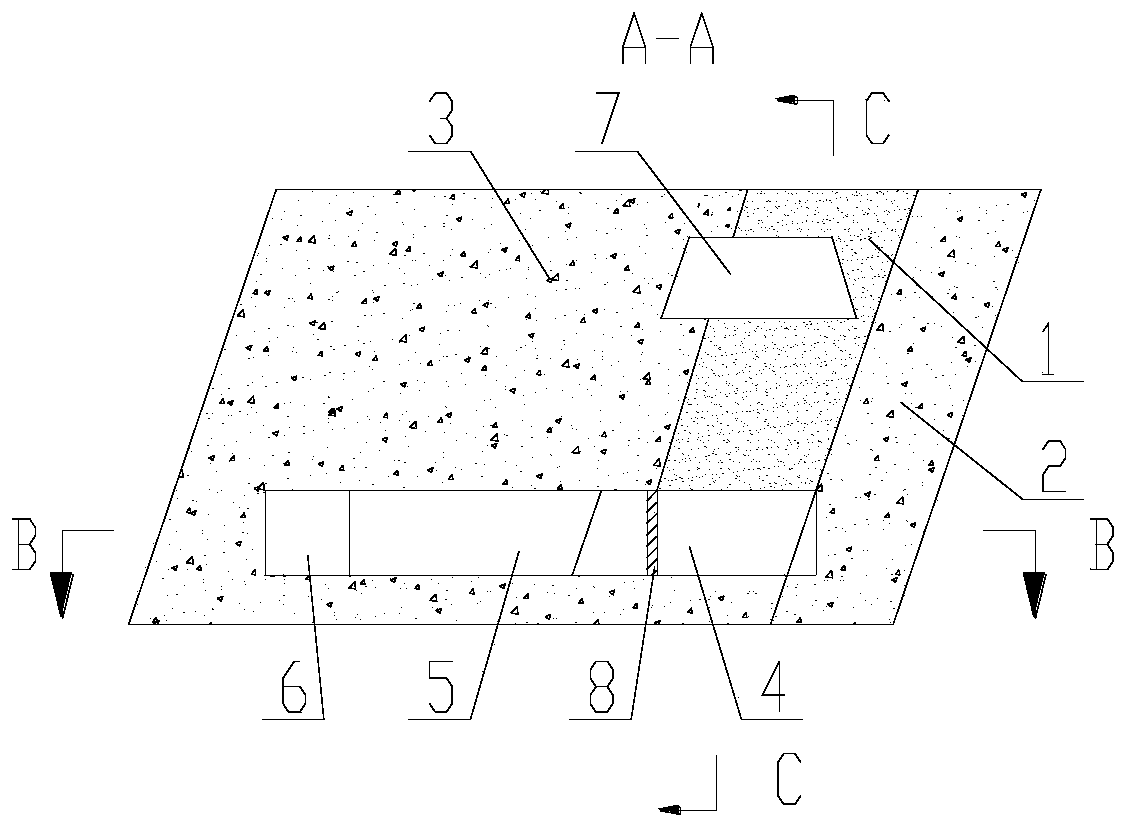

[0026] Such as Figure 3 to 9 As shown, in some demonstrative embodiments, the present invention also provides a bypass return air and extra large dip angle medium-thick coal caving mining system, including: mining coal seam 1, coal seam floor 2, coal seam roof 3, and lower air intake The transportation roadway 4, the process connection roadway 5, the bypass return air roadway 6, the upper gas roadway 7, the artificial roadway wall 8 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com