A Upward Mining Method of Steeply Inclined Thin Ore Body

A mining method and technology for thin ore bodies, which are applied to the upward mining field of steeply inclined thin ore bodies, can solve the problems of limited mining efficiency, low modernization, rock drilling, ore falling and low ore extraction efficiency, and achieve simplified mining. The effect of quasi-engineering and improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

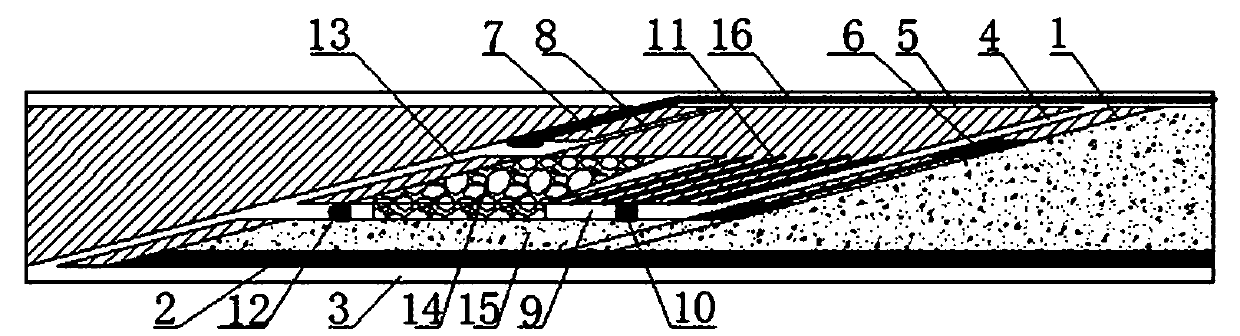

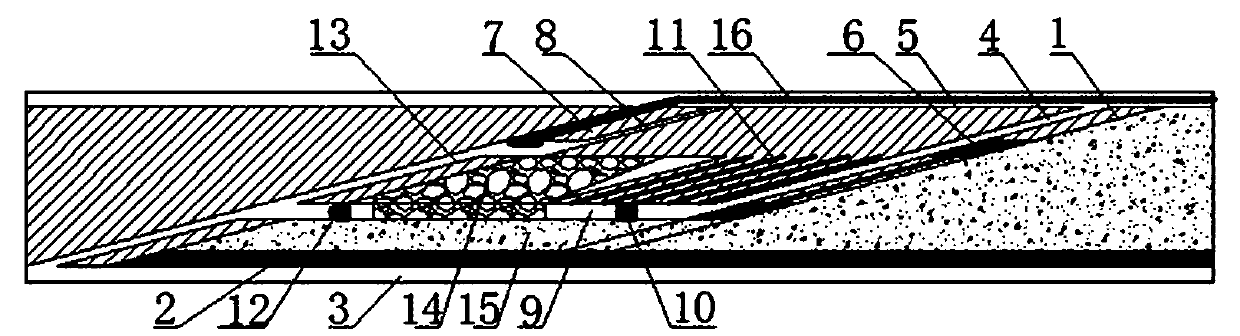

[0024] The mining method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] A lead-zinc polymetallic mine in Northwest China is a symbiotic low-grade gold ore body with an ore body dip angle of 85-90° and an average thickness of 2.0-3.5m. Supplemented by manual mining, the production capacity of the stope is only 8-12 tons per day. After adopting the mining method of the present invention, the production capacity of the stope is increased to 25-35 tons / day. Such as figure 1 Shown, the concrete steps of the upward mining method of a kind of steeply inclined thin ore body of the present invention when mining this mine are:

[0026] A. Divide the above-mentioned gold mines into ore blocks along the ore body trend, and the ore blocks are arranged in a parallelogram with an inclination angle of 15°; the length of the ore block is 60m, the width is the full thickness of the ore body, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com