A tangential-field plasma thruster capable of fine-tuning discharge performance

A technology of plasma and discharge performance, which is applied in the field of plasma thruster design, can solve the problem that the adjustment resolution does not meet the drag-free control, etc., and achieve the effect of widening the working range, enhancing the effect of the magnetic mirror, and weakening the limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

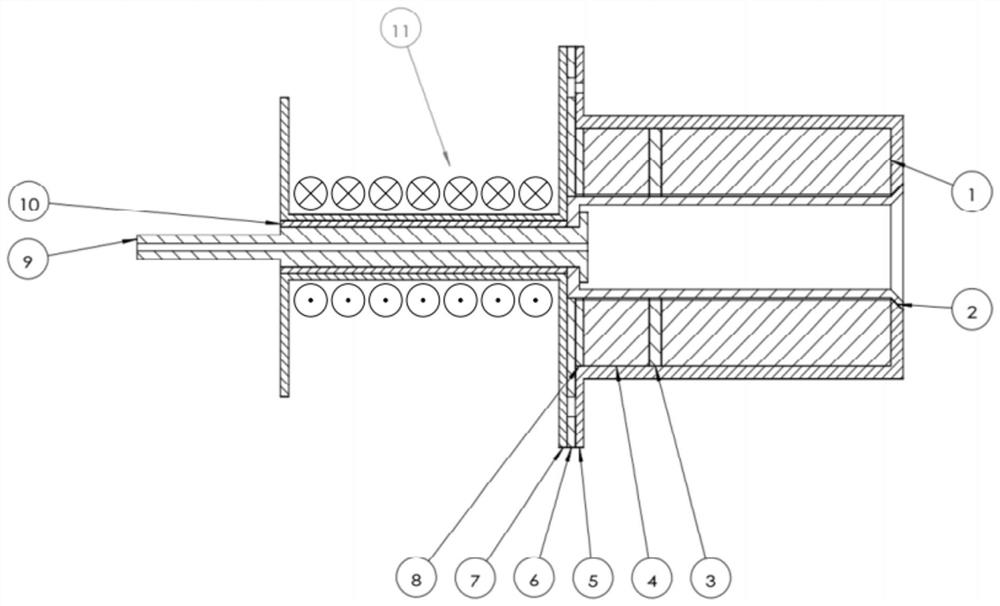

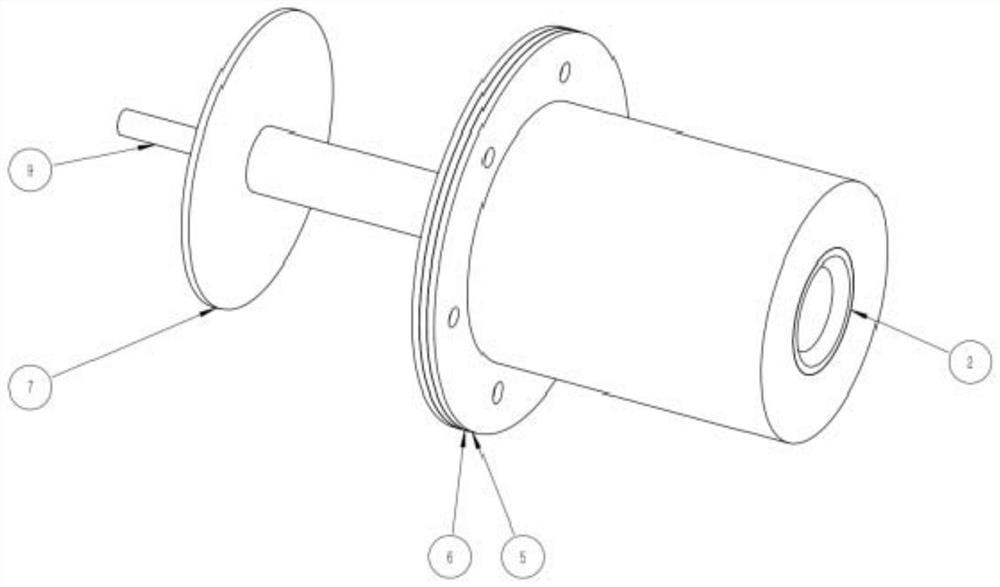

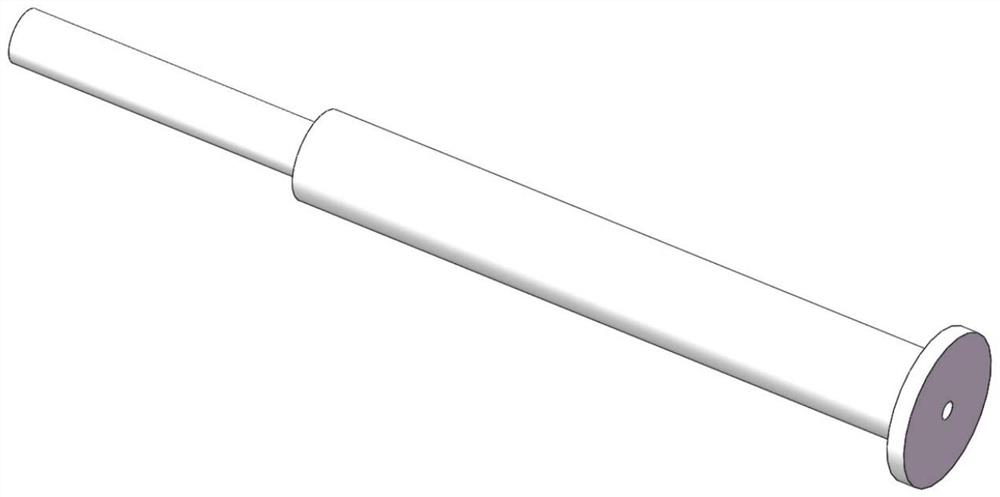

[0027] Such as Figure 1-Figure 4 As shown, a tangential field plasma thruster that can realize fine-tuning discharge performance includes a magnetically conductive anode 9 with one end set at the bottom of the ceramic channel 2 and one end as a free end, a winding sleeve 7, a ceramic ring 10 and an excitation coil 11. The magnetically conductive anode 9 is a hollow anode, and the winding sleeve 7 includes a cylindrical sleeve 701, a limiting plate 702 and a connecting plate 703, and the limiting plate 702 and the connecting plate 703 are fixedly arranged on At both ends of the cylindrical sleeve 701, a winding area is formed between the limiting plate 702 and the connecting plate 703, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com