Movable blasting protection cover plate

A protective cover, mobile technology, applied in the field of movable blasting protective cover, can solve the problems of long occupation time, increased construction investment, cumbersome procedures, etc., to reduce waste, ensure secondary utilization, and facilitate the acquisition of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below, so as to facilitate the understanding of the skilled person.

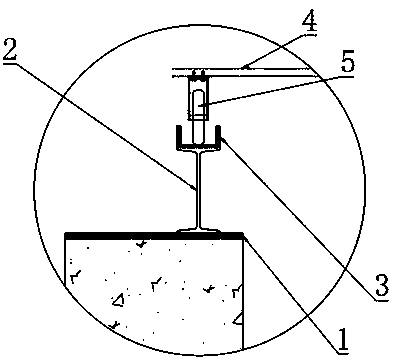

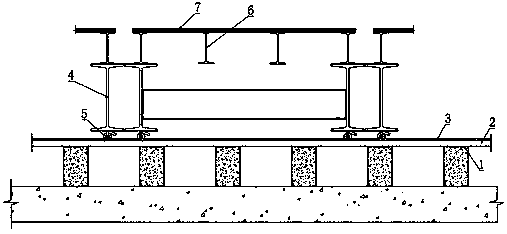

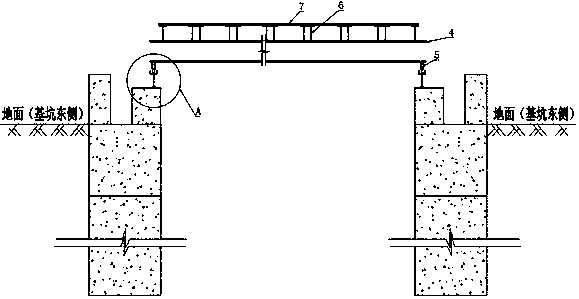

[0021] Such as Figure 1-4 As shown, a movable blasting protection cover includes a cover assembly, a support frame and a slideway assembly, the slideway assembly is installed on both sides of the foundation pit, and the cover assembly includes a cover frame 6 and a cover The plate body 7 and the cover plate frame 6 are welded by a number of I-beams. The cover plate body 7 is covered and welded on the cover plate frame 6. When welding, the I12a I-beam is used to weld a frame with a length of 9m and a width of 3m. A layer of 3 mm thick cover plate body 7 is covered on the plate frame 6 to form a cover plate assembly. The cover plate assembly is welded on the top of the support frame to form a set of single cover plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com