A tool damage detection method based on visual feature extraction

A visual feature, damage detection technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as tool damage, achieve good accuracy and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further introduced below in conjunction with the accompanying drawings.

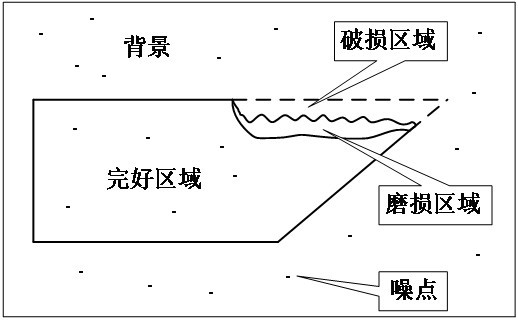

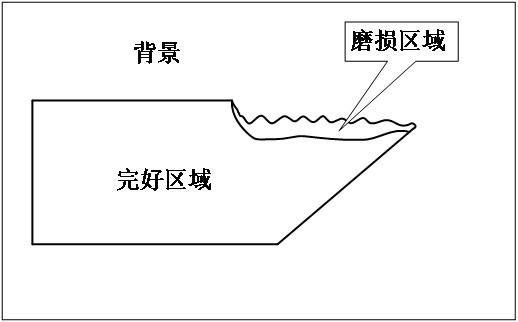

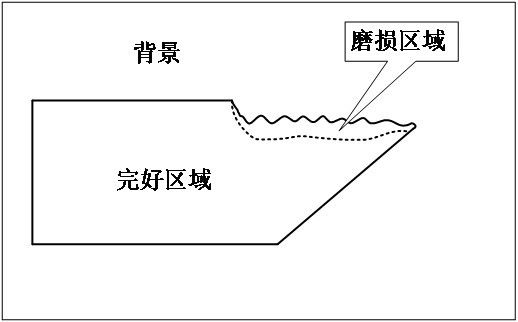

[0037] A tool damage detection method based on visual feature extraction is to divide the tool damage area into a wear area and a damaged area. The geometric features of the sum are used as the criterion for judging the degree of tool damage and the type of damage;

[0038] The tool wear area is the wear area formed by the sharp friction between the tool tip and the front and rear tool surfaces and the workpiece during the machining process; the area is obtained by image difference extraction based on the target fusion and target transfer of the tool damage image;

[0039] The tool damage area is the fine chipping and wear and tear areas that appear on the edge and tip of the tool during the tool processing; this area is extracted by collecting the intact cutting edge pixels in the image and reconstructing the upper and lower boundaries of the tool cutting edge based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com