A synchronous release tooling for on-board disconnect switch

A synchronous release and switch technology, applied in circuit breaker testing and other directions, can solve problems such as bumping stars and not meeting synchronicity requirements, and achieves the effects of convenient use, expected effects, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

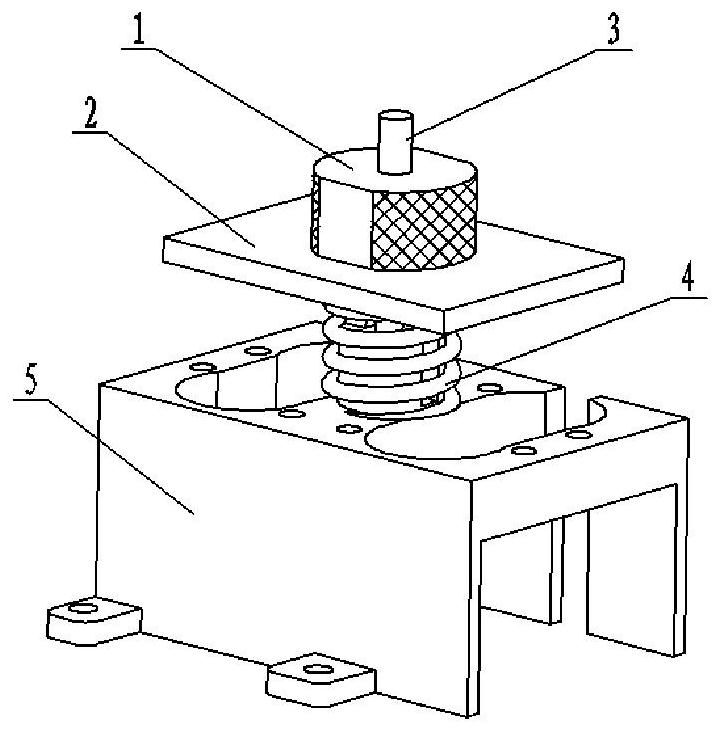

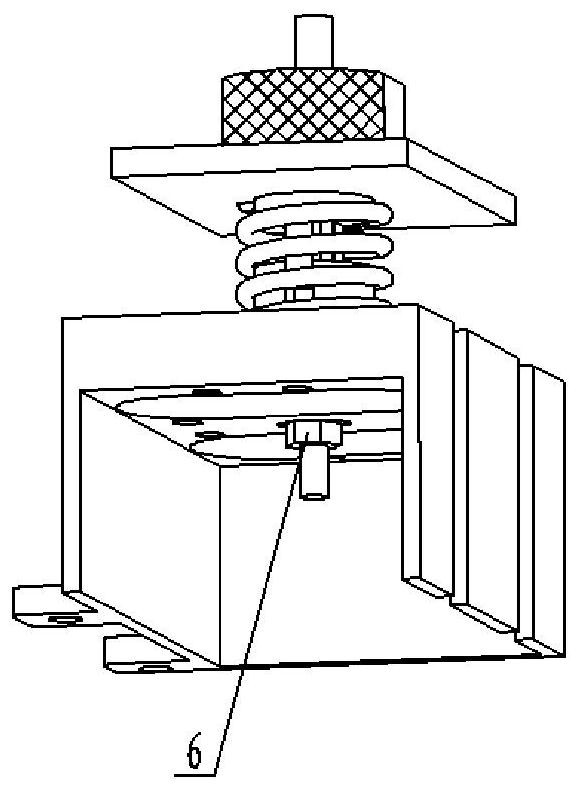

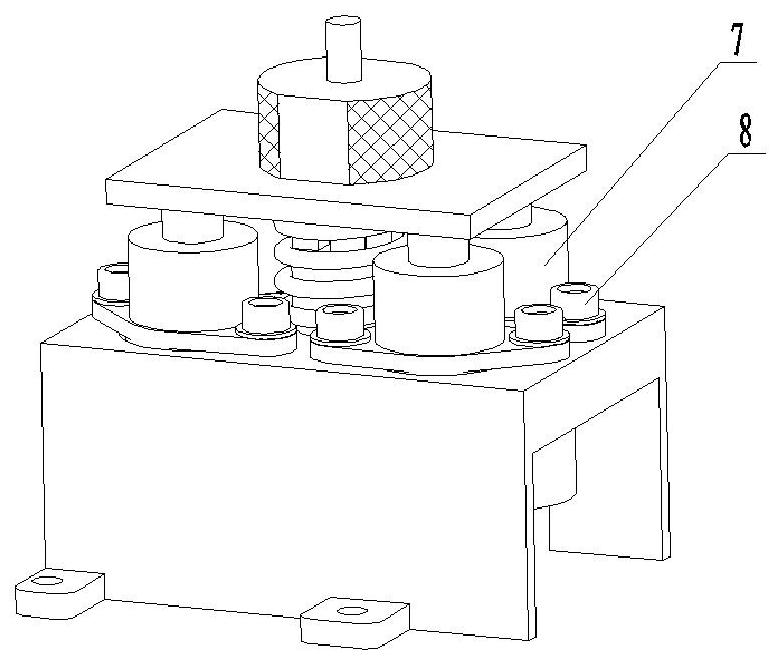

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The present invention is a tool for synchronous release of separation switches on a star, the tooling includes a mounting bracket, a guide rod, a pressure plate, a knob, a spring, and a nut; the mounting bracket is provided with a mechanical interface with a separation switch, and four separation switches can be installed at the same time; The rod has an interface with the mounting bracket; the hole on the pressure plate passes directly through the shaft of the guide rod; the spring also has an interface with the guide rod and the pressure plate; when installing, it cooperates with the fixed column between the pressure plate through the slide groove of the guide rod ; The knob has a threaded hole for connection with the guide rod, and the outer surface is knurled and trimmed; the roughness of the contact surface between the knob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com