A four-axis hydraulic locking device for a vertical machining center

A vertical machining center, hydraulic technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity, poor positioning accuracy of workpieces, etc., to improve production efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

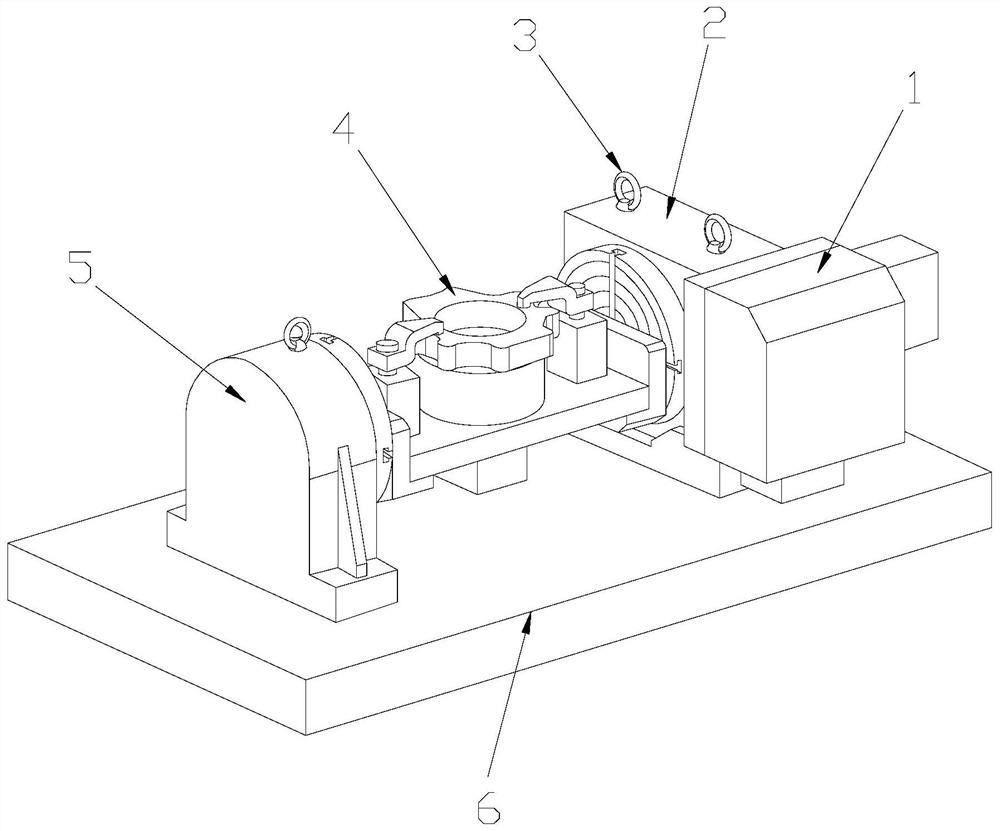

[0031] see Figure 1-Figure 4 , the present invention provides a four-axis hydraulic locking device for a vertical machining center. A four-axis hydraulic pressure 2 is provided on the right side of the top of the base 6. The base 6 and the four-axis hydraulic pressure 2 are welded by electric welding. 2 is electrically connected with the four-axis numerical control 1, and the left side of the top of the base 6 is provided with a four-axis tailstock 5, and the described base 6 is connected with the four-axis tailstock 5, and the four-axis tailstock 5 is connected to the four-axis The hydraulic shafts 2 are flexibly connected by the clamping device 4, and the four-axis tailstock 5 and the top of the four-axis hydraulics 2 are equipped with lifting rings 3;

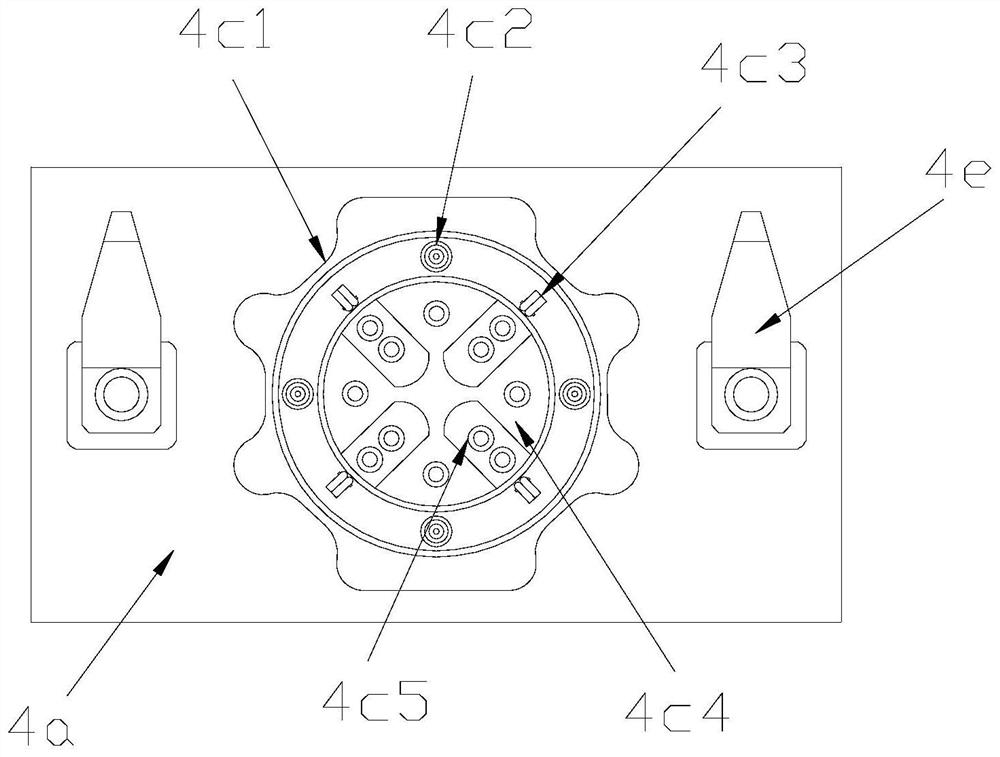

[0032] The clamping device 4 is composed of a workbench 4a, an air control valve 4b, a positioning sealing mechanism 4c, an air pipe 4d, and a corner cylinder 4e. An air control valve 4b is installed at the middle position...

Embodiment 2

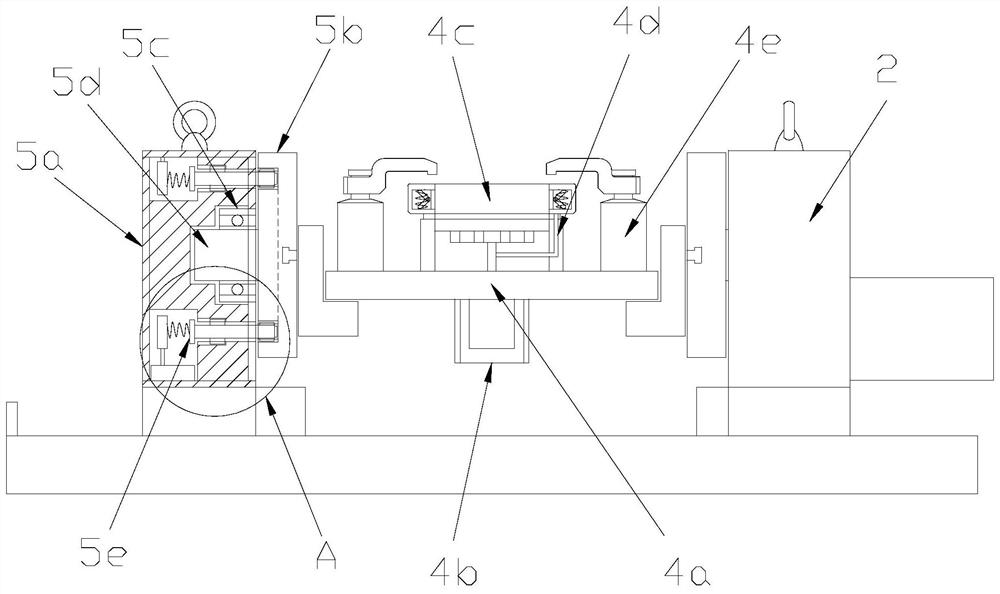

[0038] see Figure 1-Figure 7 , the present invention provides a four-axis hydraulic locking device for a vertical machining center. The four-axis tailstock 5 is composed of a body 5a, a rotary chuck 5b, a bearing ring 5c, a rotating shaft 5d, and a locking mechanism 5e. A rotating shaft 5d is provided at the middle position of the rear end of the rotating chuck 5b, the rotating chuck 5b is fixedly connected to the rotating shaft 5d, the rotating shaft 5d is arranged inside the body 5a, and the rotating shaft 5d and the body 5a pass through the bearing ring 5c Clearance fit, the inside of the body 5a is equipped with a locking mechanism 5e up and down, and the locking mechanism 5e cooperates with the rotary chuck 5b.

[0039] The back surface of the rotary chuck 5b is provided with an inner gear ring groove 5b1.

[0040] The locking mechanism 5e is composed of an electromagnet 5e1, a second spring 5e2, an armature 5e3, a locking lever 5e4, and a first slide rail 5e5. The righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com