Rapid switching standardized structure for machining clamps and arranging method thereof

A design method and fixture technology, applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of waste of personnel and related resources, bruises on the working surface of equipment, long cumulative replacement time, etc., and achieve good use effect and economical effect, the effect of preventing excessive weight of the jig, and reducing the risk of bad outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

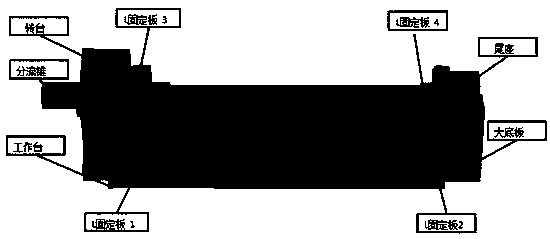

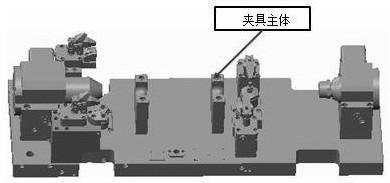

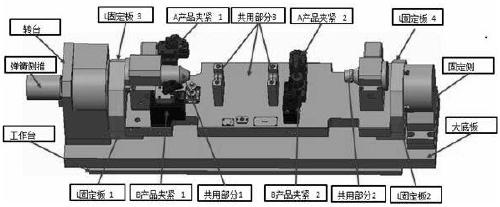

[0018] The standardized structure of processing fixture quick change includes a standardized base 1, which is used to install different fixture main bodies 2; the two sides of the standardized base 1 are provided with clamping structures 3 for fixing the fixture main body 2, and the two clamping The configuration of the structure 3 satisfies that the distance between the two clamping structures 3 can be adjusted, the height of the upper and lower centers of the two clamping structures 3 can be adjusted, and the left and right positions of the two clamping structures 3 can be adjusted.

[0019] Further, the clamping structure 3 includes two correspondingly arranged L-shaped fixing plates 4 , and the outside of the L-shaped fixing plates 4 is provided with a turntable 5 and a lifting platform 6 for adjusting the position of the L-shaped fixing plate 4 .

[0020] Further, the side of the L-shaped fixing plate 4 facing the clamp body 2 is provided with fastening holes, and the fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com