Mechanical hand joint connection device

A technology of connecting device and manipulator, applied in manipulators, joints, manufacturing tools, etc., can solve the problems of large damper size, inconvenient joint detection, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

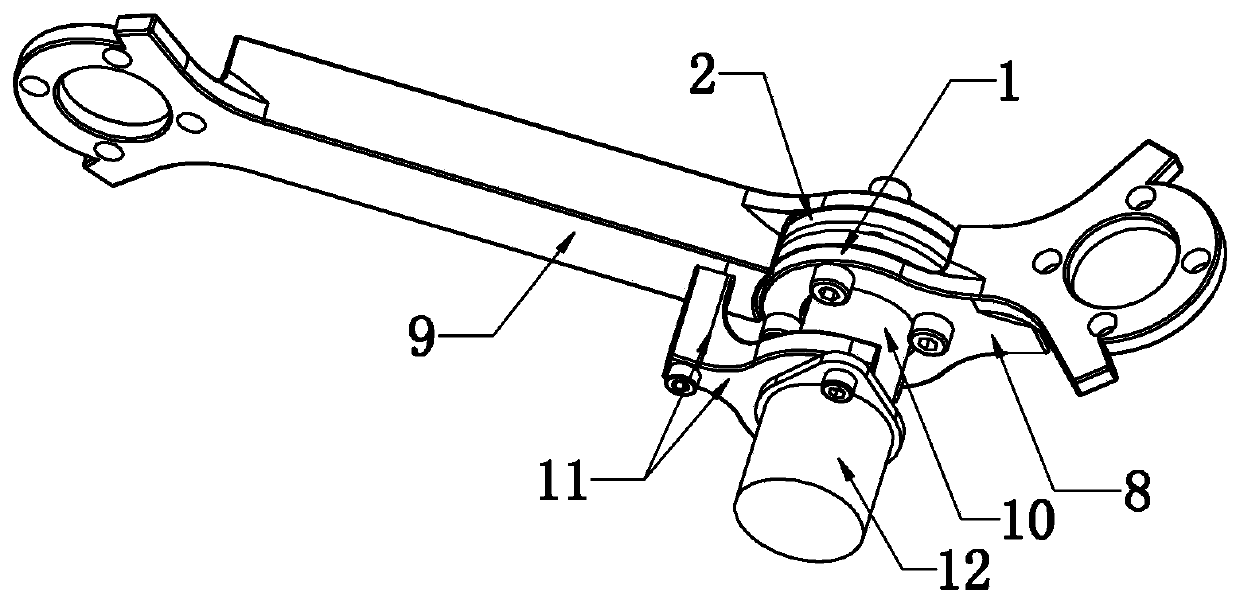

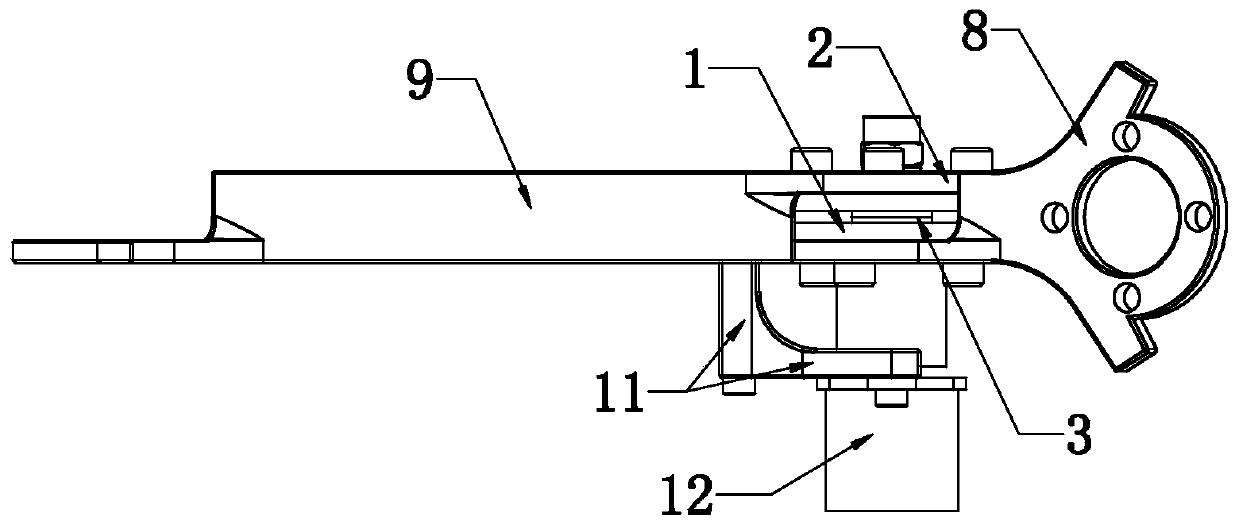

[0023] As shown in the figure, the manipulator joint connection device of the present invention includes a fixed disc 1 with a central flat hole, a rotating disc 2 with a central circular hole, an intermediate metal sheet 3 with a central flat hole, a flat pin shaft (with a flat screw pin shaft) 6 and the side metal sheet 5 that also has a central flat hole, the flat pin shaft 6 passes through the fixed disk 1, the middle metal sheet 3, the rotating disk 2, and the side metal sheet 5 in turn, and then the disc spring 4 is set and passed through the fastener (Self-locking nut) is locked and fixed, wherein the structure of the fixed plate 1 is as follows Image 6 As shown, there are four evenly distributed threaded connection holes, and the center has double-sided oblate holes (flat through holes). The rotating disk 2 also has the same four uniformly distributed connecting holes as the fixed disk 1. The difference is that the rotating disk 2 The center is a circular hole, and th...

Embodiment 2

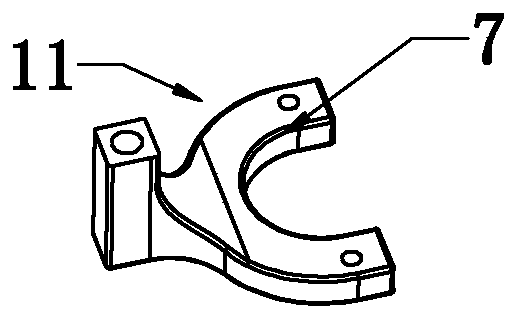

[0025] On the basis of Embodiment 1, further in order to meet the detection requirements, the middle part of the fixed plate 1 is fixedly connected with the connection block 10 by screwing. In order to make the structure compact, the bottom surface of the connection block 10 is provided with a bottom hole for accommodating the flat pin shaft 6 13. After the connecting block is fixedly installed on the fixed plate, the head of the flat pin shaft is limited in the bottom hole, and the second joint arm 9 is fixedly connected with the sensor bracket 11 by screws, and the top of the sensor bracket 11 is set in a C shape The connecting arm 7 and the angle sensor 12 are connected to the C-shaped connecting arm 7 by means of screws through the mounting flange. Simultaneously, because the sensor bracket 11 is screwed to the second articulated arm 9, the mounting flange of the angle sensor 12 is equivalent to the rotating disk 2. Fixed connection, the bottom end of the angle sensor 12 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com