A flexible follower ring suitable for composite gas cylinders

A composite material and flexible technology, applied in the method of container discharge, the manufacture of the container structure, the outer wall of the container structure, etc., can solve the problems of deformation consistency, poor coordination, and difficult assembly of ultra-thin-walled linings, etc., to solve deformation Inconsistencies, improved reliability and safety, effects of avoiding weld spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Filament-wound gas cylinders, the thickness of the ultra-thin-walled inner lining is 0.4mm to 1.5mm, and the inner diameter is not greater than 1200mm;

[0026] The flexible follower ring for the above-mentioned fiber-wound gas cylinders is a ring structure with variable thickness, which is divided into a flexible part with a thinner wall and a rigid part with a thicker wall along its axial direction. The upward height ratio is 0.5~1.5:1;

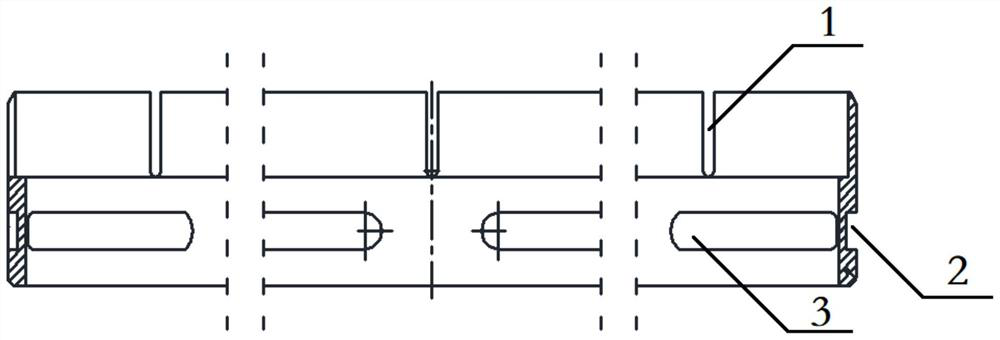

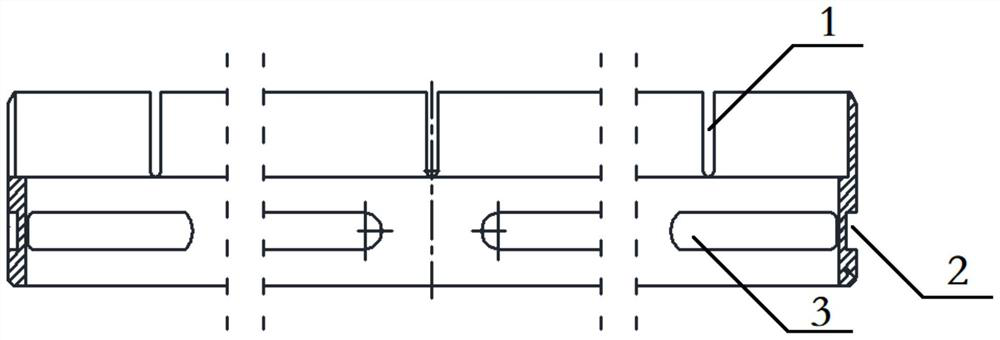

[0027] The wall thickness of the flexible part is less than the wall thickness of the ultra-thin-walled lining and not less than 1 / 2 of the wall thickness of the ultra-thin-walled lining, and U-shaped notches 1 equal to the number of welding spots are processed in the axial direction on the flexible part. And the U-shaped gap 1 is evenly arranged in the circumferential direction of the flexible part, so that the flexible part forms an open ring structure, such as figure 1 shown;

[0028] The wall thickness of the rigid part is grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com