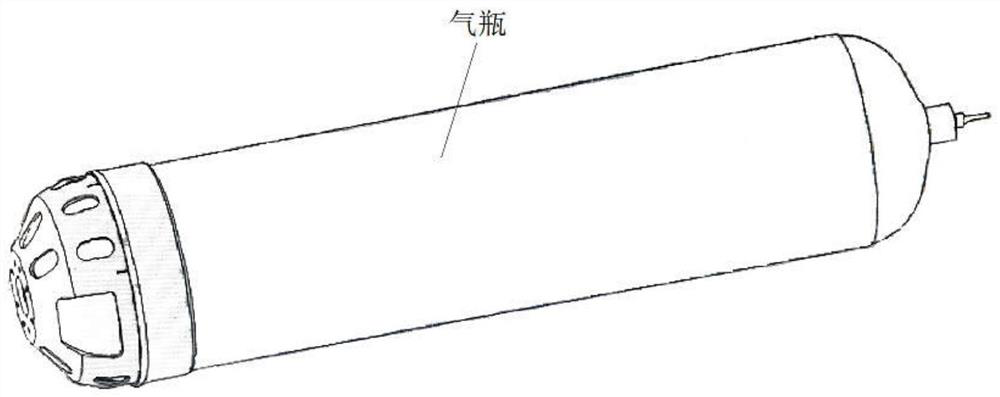

Flexible fastening mounting bottom cover for heavy-load slender winding gas cylinder

A winding gas cylinder, slender technology, which is applied in the field of flexible fastening installation bottom cover, can solve the problem of unsuitable volume of the installation interface, achieve good follow-up deformation ability, good connection ability, and improve the effect of mechanical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

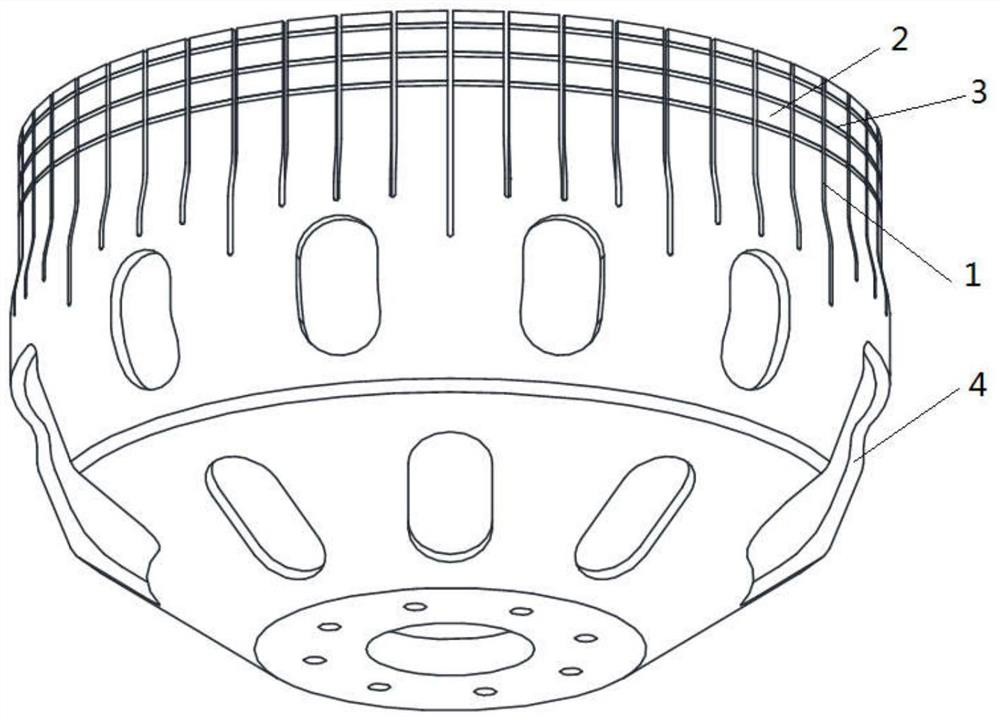

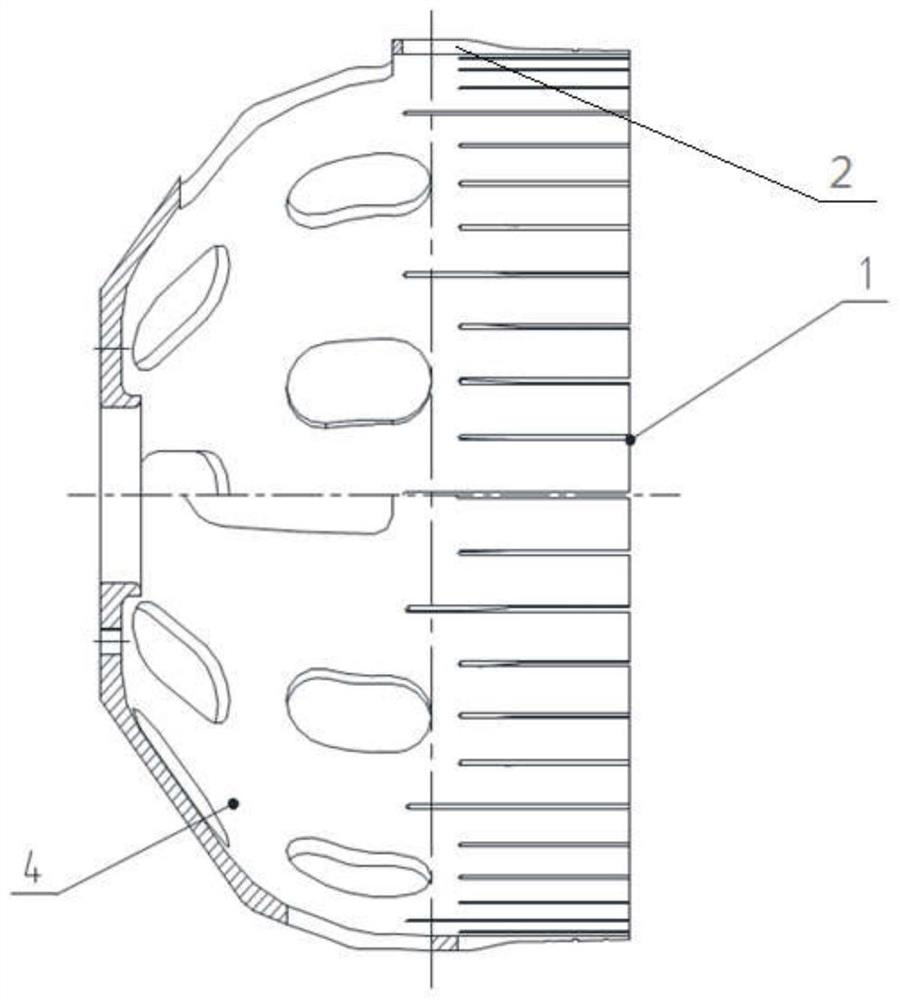

[0048] A specific embodiment of the flexible fastening installation bottom cover for heavy-duty elongated wound gas cylinders of the present application is as follows:

[0049] Carbon fiber wound slender, high-pressure thin-walled xenon cylinder made of heavy-duty composite materials, the base wall thickness of the thin-walled inner lining is 0.8mm, the load capacity is 181.5kg, the length is 1643mm, the diameter is φ300mm, and the aspect ratio is 5.5;

[0050] For the flexible fastening installation bottom cover of the above-mentioned carbon fiber wound composite gas cylinder, along its axial direction, it is divided into a flexible structure with a thin wall thickness (60mm in length) and a rigid structure with a thicker thickness (140mm in length). The thin wall thickness of the flexible structure is 1.2mm Gradually change to 2mm (inclination of about 1°), 48 opening expansion grooves with a width of 1mm are evenly distributed on the circumference of the installation bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com