Wet curtain missing installation protective structure and tower type cooling fan

A protective structure and wet curtain technology, applied in heating methods, air humidification systems, natural cooling systems, etc., can solve electrical safety hazards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

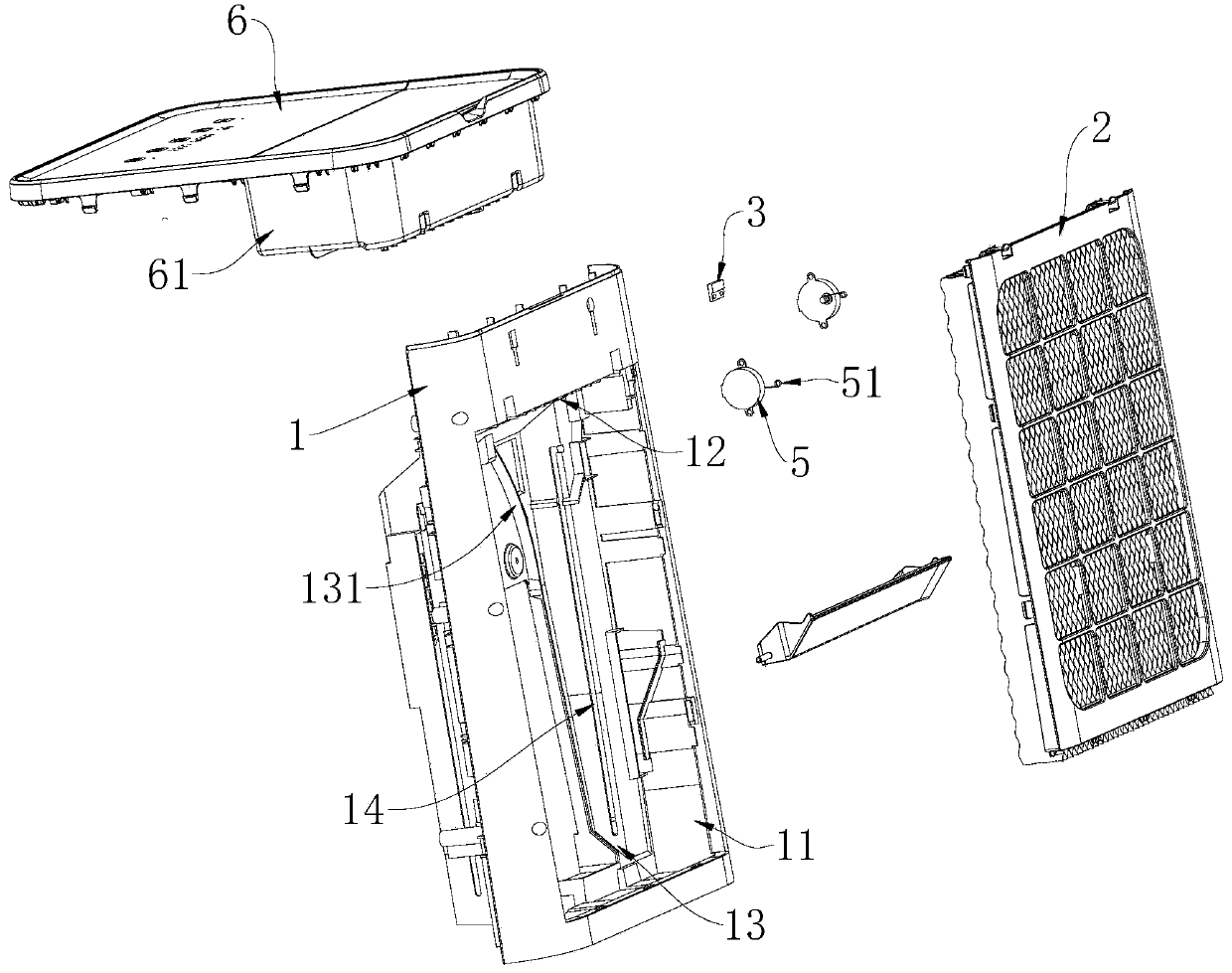

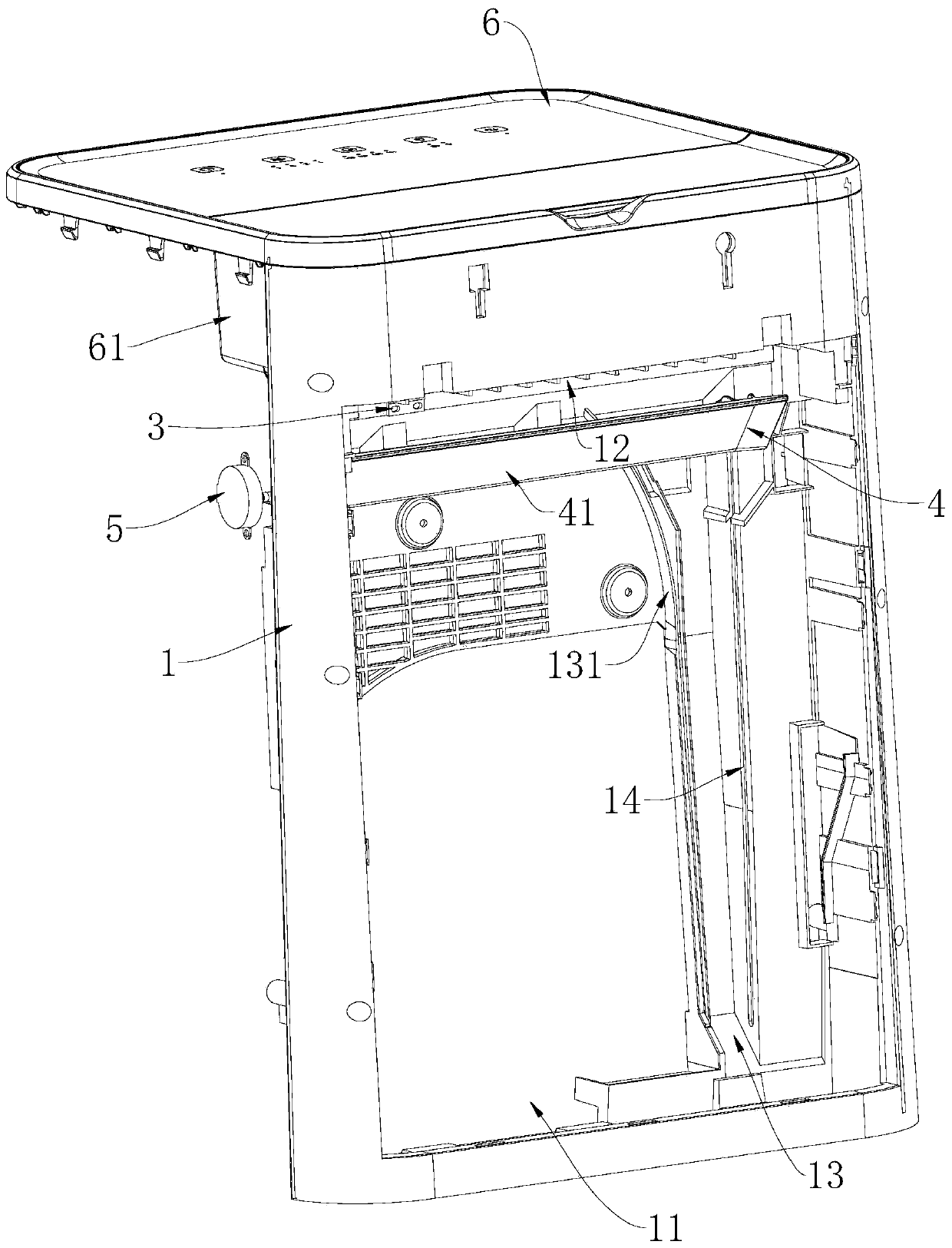

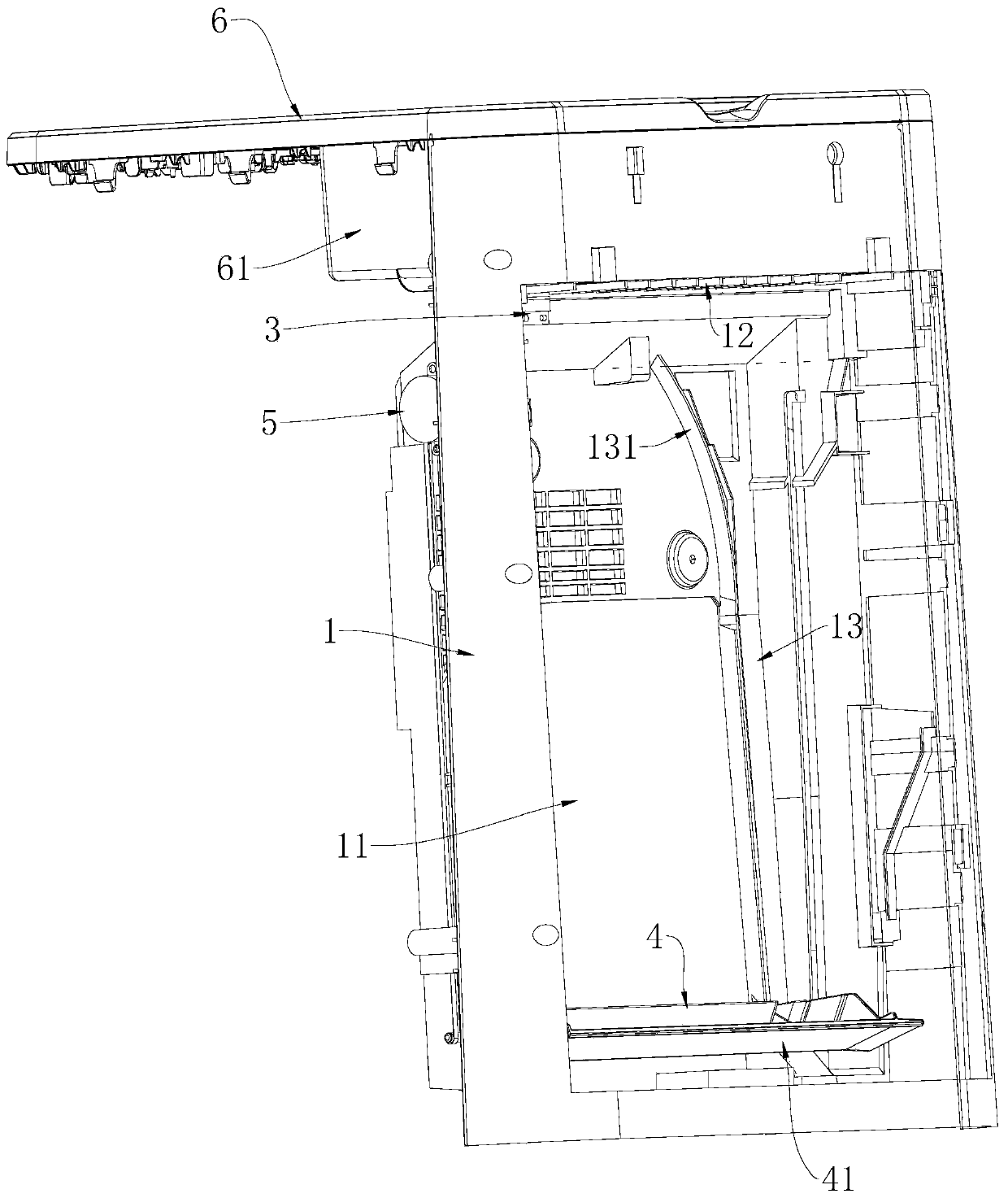

[0046] This embodiment provides a protective structure for wet curtain leakage, such as figure 1 , figure 2 , image 3 As shown, it includes: a rear case 1 and a wet curtain 2, the rear case 1 includes a mounting groove 11, the wet curtain 2 is detachably mounted on the rear case 1, and the wet curtain 2 closes the installation groove 11, the installation groove 11 is provided with a water supply port 12 for supplying water to the wet curtain 2; the water receiving tank 4 is located in the installation groove 11, and the water receiving tank 4 is controlled by the movement of the driving mechanism , the water receiving tank 4 has a first state set close to the water supply port 12, and a second state set away from the water supply port 12; the sensor switch 3 is set on the wet curtain 2 and / or the rear shell 1, the induction switch 3 is used to detect whether the wet curtain 2 is installed, and the driving mechanism is controlled by the induction switch 3. The sensor switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com