Porous carbon film of fuel cell gas diffusion layer and preparation method thereof

A gas diffusion layer and fuel cell technology, which is applied in fuel cells, electrical components, circuits, etc., can solve the problems of restricting the application and development of fuel cell gas diffusion layers, unfavorable industrial production, and high energy consumption. The effect of high strength and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

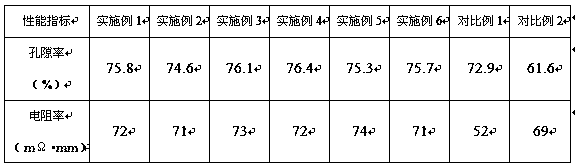

Examples

Embodiment 1

[0031] (1) Mix and stir the modified carbon nanotubes with ethylenediamine, PVP, resin film former, and deionized water for 2 hours to prepare an infiltration solution, then put the glass fiber in the infiltration solution for 24 hours, and then add hydrophobic agent, conductive agent, diluent, and expansion pore-forming agent, mixed and stirred for 1 hour to obtain a precursor solution; the preparation method of modified carbon nanotubes is to mix carbon nanotubes with concentrated nitric acid at 1g: 80ml, and heat to 85 ℃ and reflux at constant temperature for 6 hours, then cool, filter, and dry; the resin film-forming agent is epoxy resin; the hydrophobic agent is polytetrafluoroethylene; the conductive agent is carbon black; the diluent is methyl acrylate; the expansion pore-forming agent is Polyaniline coated 2,4,6-triisopropyl-1,3,5-trioxane;

[0032] The ratio of each raw material is, by weight, 3 parts by weight of modified carbon nanotubes, 3 parts by weight of ethyle...

Embodiment 2

[0036](1) Mix and stir the modified carbon nanotubes with ethylenediamine, PVP, resin film former, and deionized water for 2 hours to prepare an infiltration solution, then put the glass fiber in the infiltration solution for 24 hours, and then add hydrophobic agent, conductive agent, diluent, and expansion pore-forming agent, mixed and stirred for 1 hour to obtain a precursor solution; the preparation method of modified carbon nanotubes is to mix carbon nanotubes with concentrated nitric acid at 1g: 80ml, and heat to 85 ℃ and reflux at constant temperature for 6 hours, then cool, filter, and dry; resin film-forming agent is polyacrylic acid resin; hydrophobic agent is polyhexafluoropropylene; conductive agent is conductive acetylene black; diluent is butyl acrylate; expansion pore-forming agent Coating polyaniline with 2,4,6-triisopropyl-1,3,5-trioxane;

[0037] The ratio of each raw material is, by weight, 5 parts by weight of modified carbon nanotubes, 1 part by weight of e...

Embodiment 3

[0041] (1) Mix and stir the modified carbon nanotubes with ethylenediamine, PVP, resin film former, and deionized water for 2 hours to prepare an infiltration solution, then put the glass fiber in the infiltration solution for 24 hours, and then add hydrophobic agent, conductive agent, diluent, and expansion pore-forming agent, mixed and stirred for 1 hour to obtain a precursor solution; the preparation method of modified carbon nanotubes is to mix carbon nanotubes with concentrated nitric acid at 1g: 80ml, and heat to 85 ℃ and reflux at constant temperature for 6 hours, then cool, filter, and dry; the resin film-forming agent is polyacrylic acid resin; the hydrophobic agent is polyvinylidene fluoride; the conductive agent is carbon black; the diluent is methyl methacrylate; expansion pores The agent is polyaniline coated 2,4,6-triisopropyl-1,3,5-trioxane;

[0042] The ratio of each raw material is, by weight, 8 parts by weight of modified carbon nanotubes, 2 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com