Pipe cable hoop and pipe cable laying assembly

A pipeline cable and cable technology, which is applied in the direction of cable laying equipment, etc., can solve the problems of affecting the service life of the cable, scratches on the outer wall of the cable, and cannot solve the sliding friction between the outer wall of the cable and the inner wall of the pipeline, so as to prevent damage and reduce traction resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

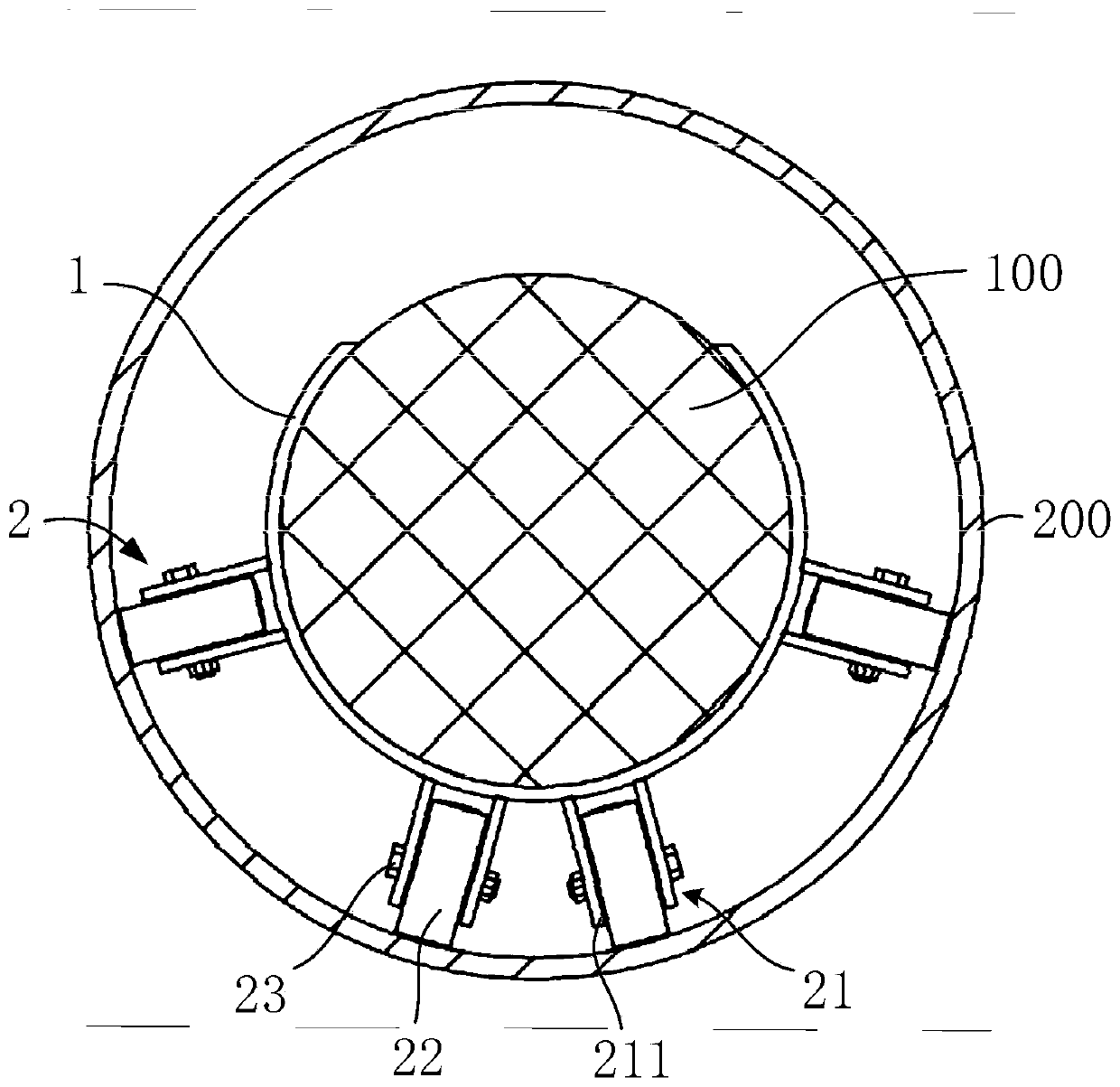

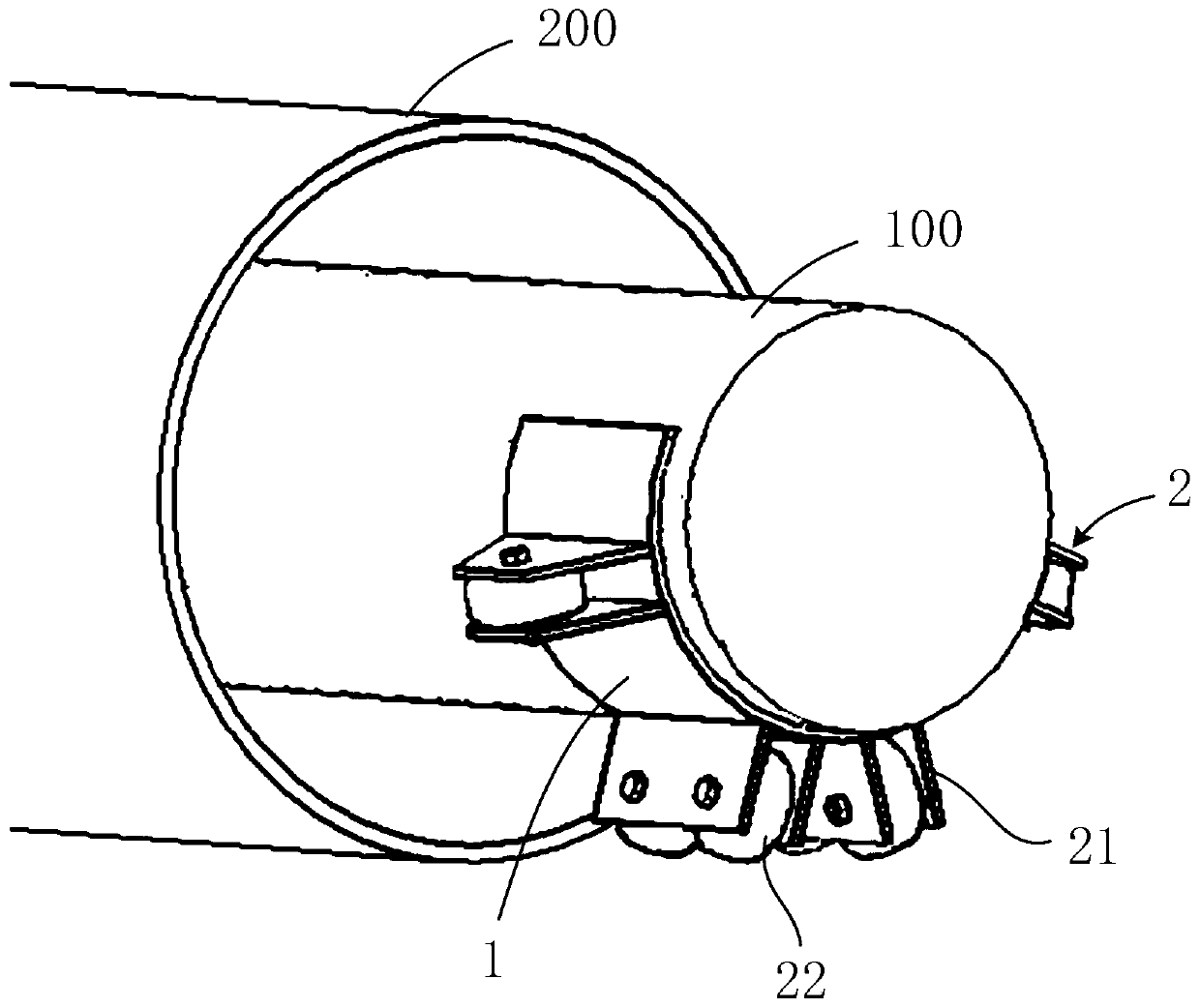

[0036] This embodiment provides a pipeline cable laying assembly, which can be applied in the field of cable laying, especially in the construction of pipeline cable laying. The pipeline cable laying assembly includes a plurality of pipeline cable hoops, and each pipeline cable hoop is arranged in parallel to be installed on the outer wall of the cable at intervals. When the cable is pulled by the traction machine and laid into the pipeline, each pipeline cable hoop can be used as a supporting structure between the outer wall of the cable and the inner wall of the pipeline, which can reduce the traction resistance of the traction machine and prevent the cable from rubbing against the inner wall of the pipeline. resulting in damage. Next, the pipe cable hoop will be described in detail.

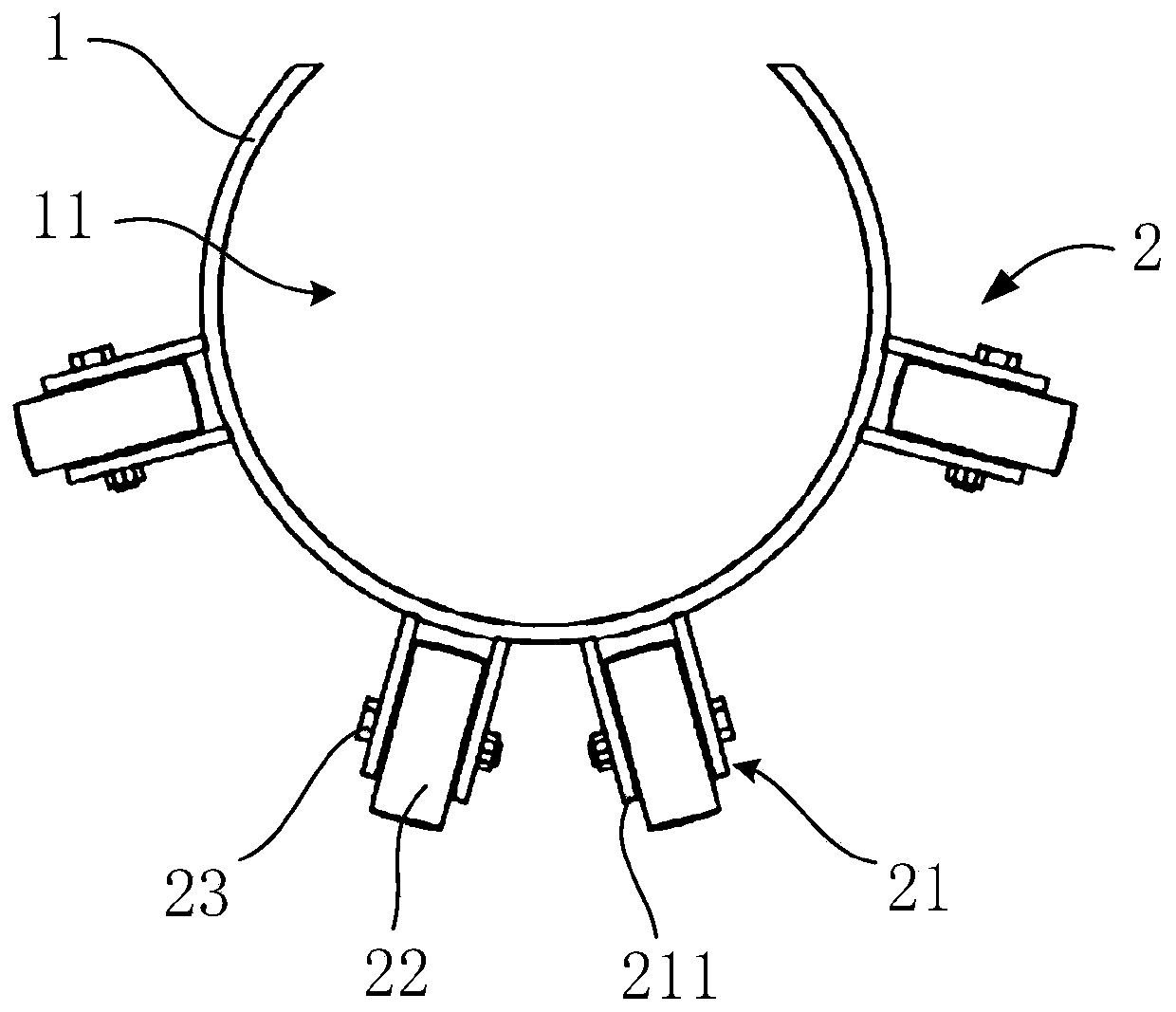

[0037] see figure 1 and combine figure 2 , the pipe cable hoop includes a hoop body 1 and at least two support bodies 2 . The ferrule 1 has a notch 11 capable of fitting and connecting wi...

Embodiment 2

[0054] see Figure 5 The difference between the pipe cable hoop provided in this embodiment and the pipe cable hoop in the previous embodiment is that the support body 2 is only symmetrically arranged on both sides near the bottom of the hoop body 1, or one of the support bodies 2 Located at the bottom of the hoop body 1, it is symmetrically arranged on both sides of the support body 2 to form an inferior arc-shaped arc-shaped support portion. That is, the pipe cable hoop provided in this embodiment can be suitable for laying the cable 100 in a straight pipe 200, and reduce the number of supports 2 arranged on both sides of the hoop body 1, saving cost and lightening the pipe cable. The weight of the hoop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com