Split roller for rolling forming of surface microgroove

A micro-groove and split-type technology, which is applied in the field of metal plastic forming, can solve the problems of weakened drag reduction performance, difficult turning, difficult to process curved surface streamlines, etc., to reduce processing and use costs, improve sharp corner forming quality, replace and the effect of convenient combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The exemplary embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] The technical solution in this example will be described in detail below with reference to the drawings in the exemplary embodiment of the present invention.

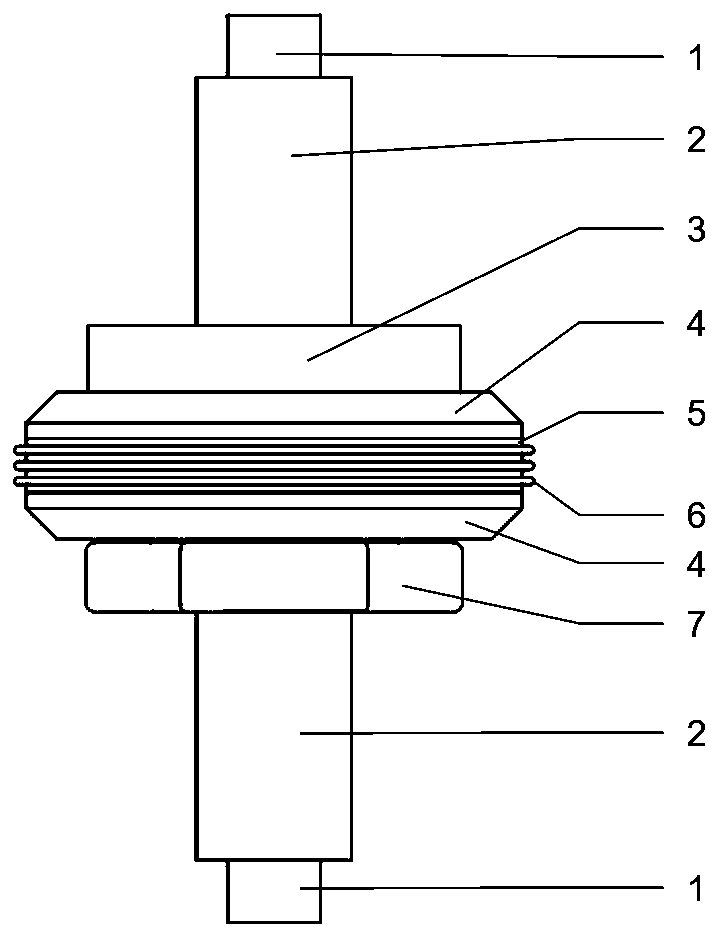

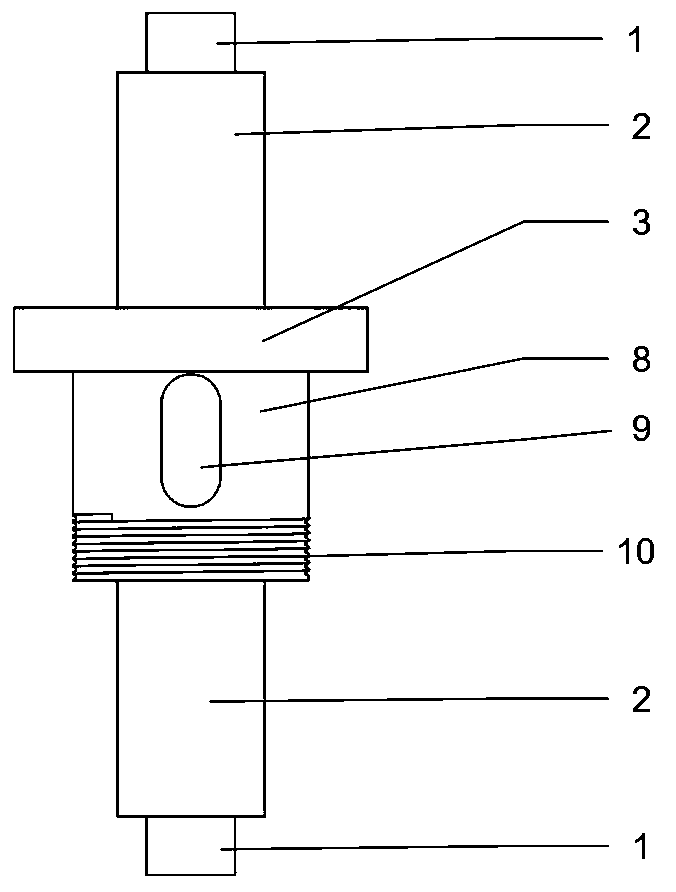

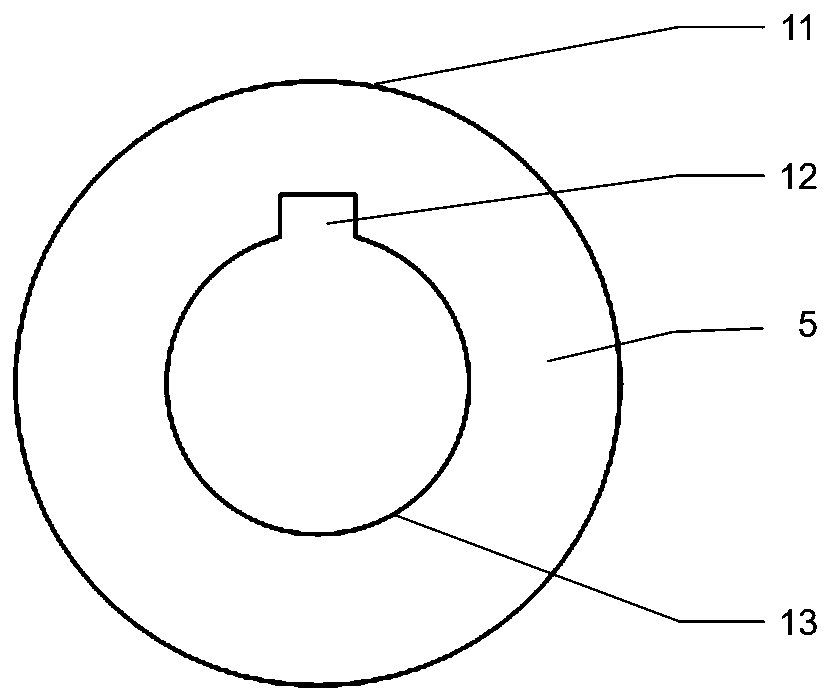

[0030] Such as figure 1 As shown, a kind of micro-groove rolling split roller provided by the present invention, such as figure 1 As shown, it includes roller main shaft, blades 5 and 6, thick block 4 and nut 7; as figure 2 As shown, the two ends of the main shaft of the roller are provided with a step 1 for placing the thrust bearing, and the inner side of the thrust bearing step 1 is provided with a needle bearing step 2, and one end of the inner side is provided with a shaft shoulder 3 with a diameter of 28 mm and a thickness of 4 mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com