Double-station automatic molding machine

A molding machine and double-station technology, applied in the field of machinery, can solve the problems of fixed sand storage box, troublesome debugging, short service life, etc., and achieve the effect of smooth sand pushing process, good working stability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

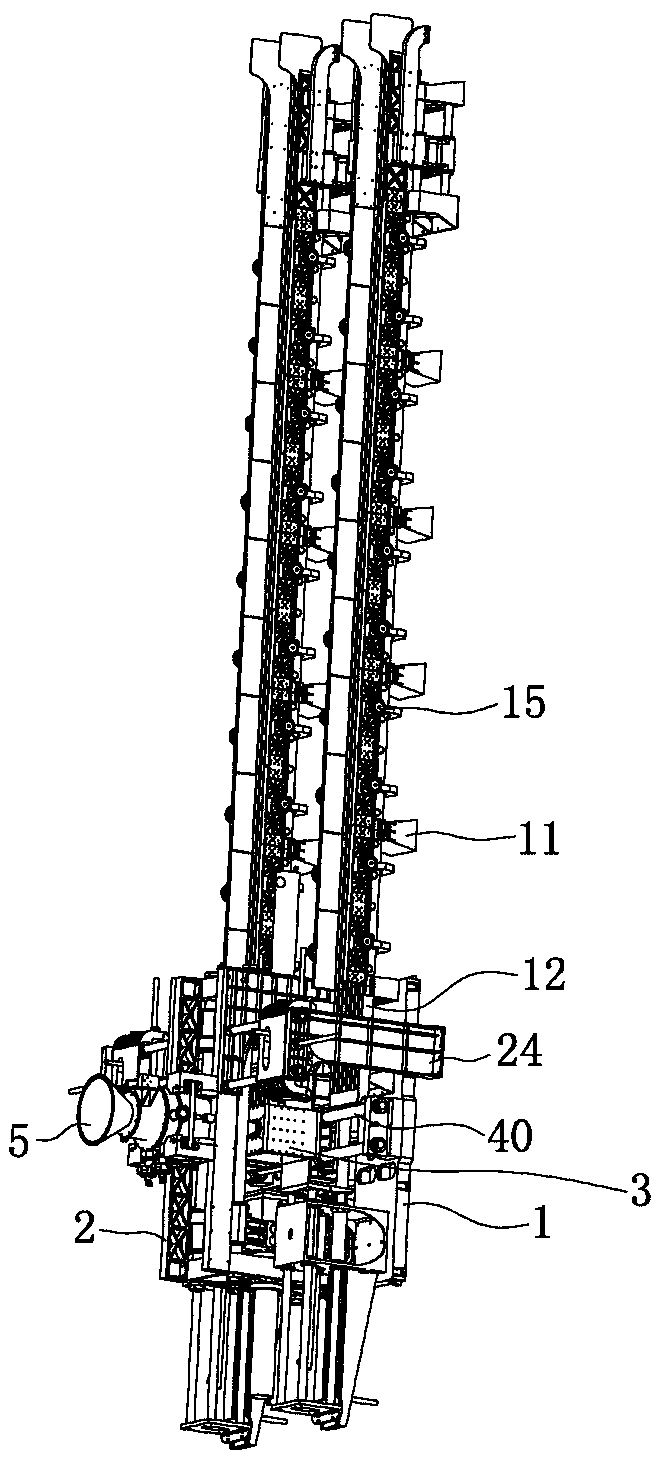

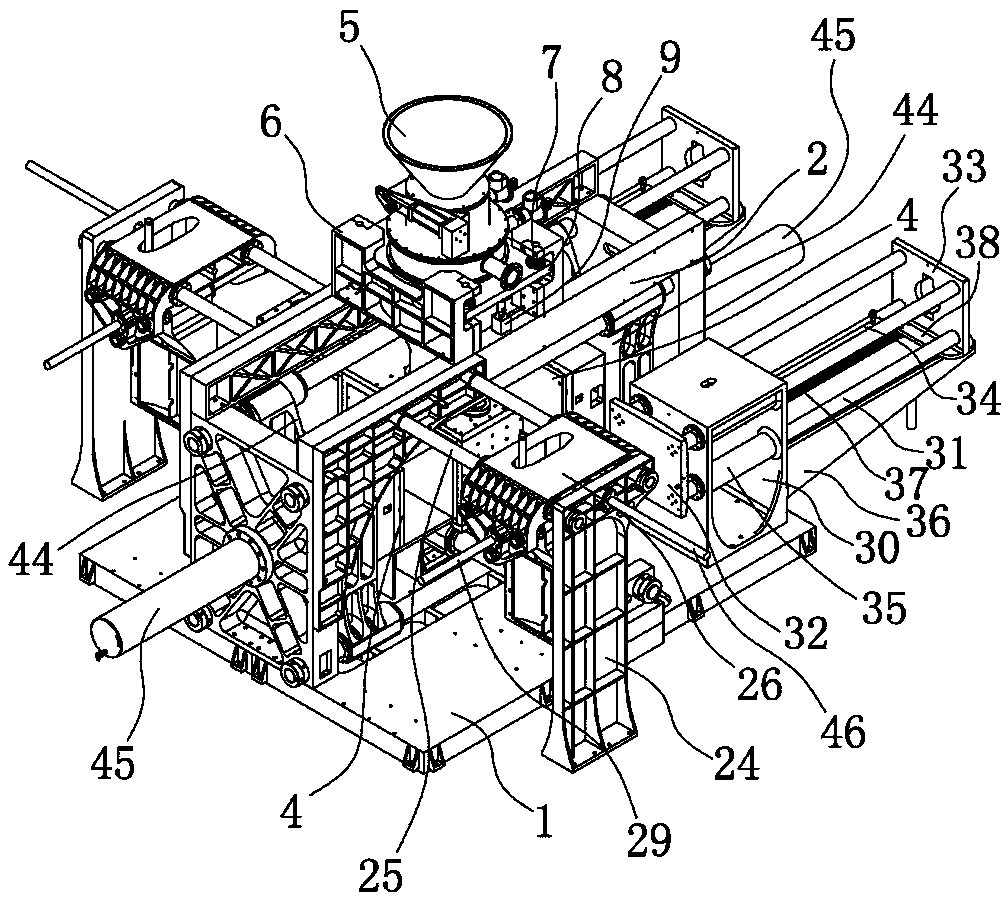

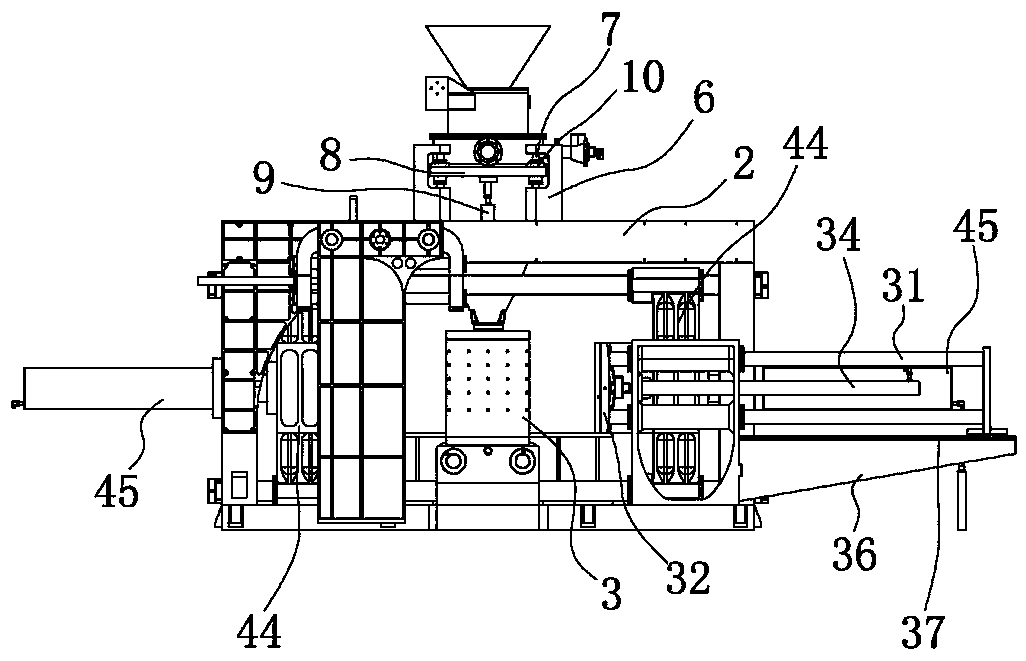

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the double-station automatic molding machine includes a base 1, and the base 1 is provided with a horizontally arranged fixed frame 2 and a push-type box device that passes through the fixed frame 2 longitudinally to push two molded boxes 3 to move longitudinally. Both lateral ends of 2 are provided with pusher devices that push the respective molds 4 to move laterally back and forth. The pusher devices include movable brackets 44 installed on the fixed frame 2. The movable brackets 44 are fixedly connected with corresponding molds 4 and fixed frame 2. The mold pushing cylinder 45 that promotes the longitudinal displacement of the movable support 44 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com