Easy-to-adjust intelligent carbon skateboard external arc grinding equipment and grinding method

A carbon sliding plate, intelligent technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of long grinding time, slow work efficiency, troubled manufacturers, etc., to reduce work difficulty and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

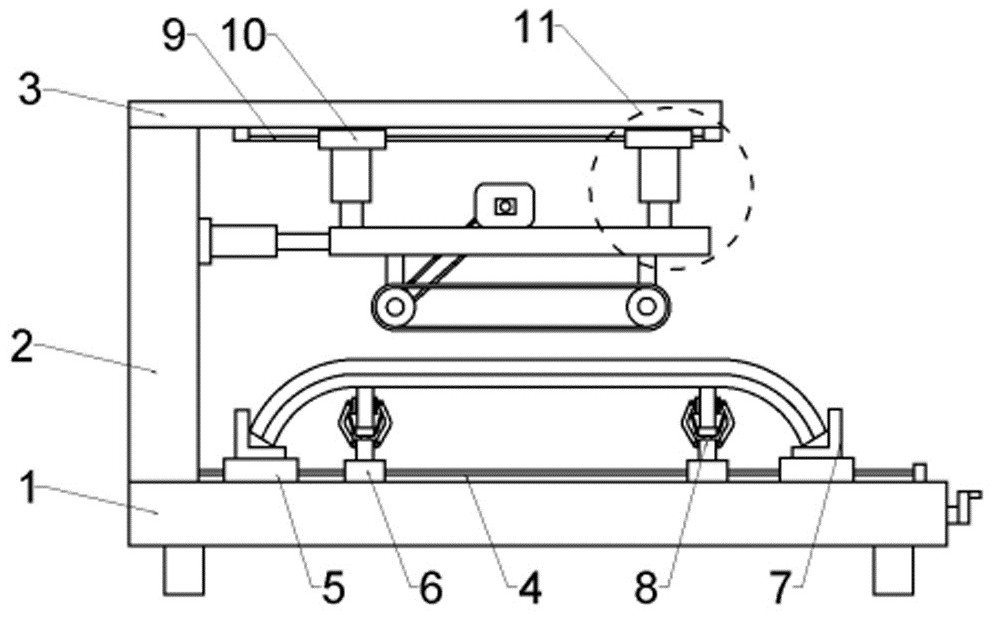

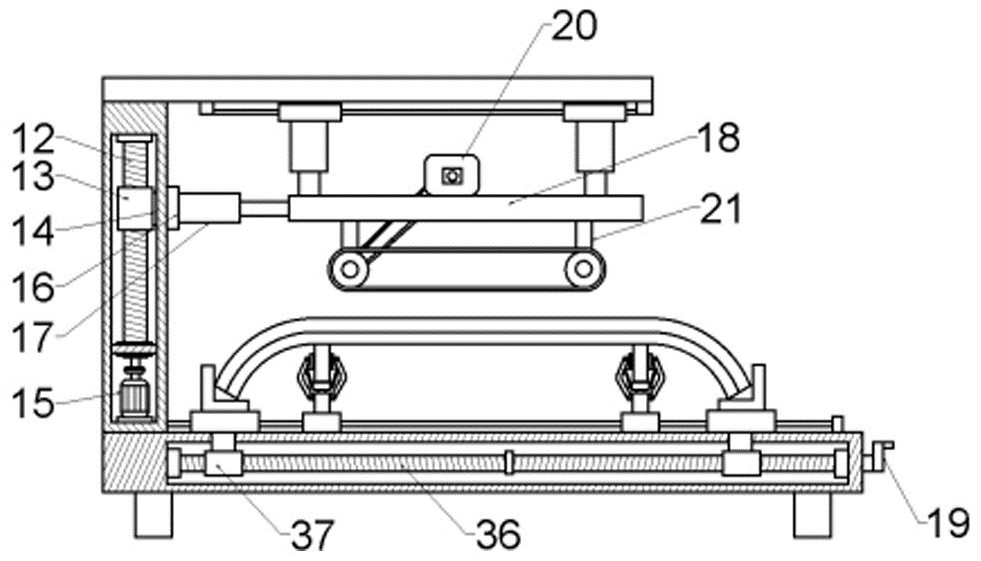

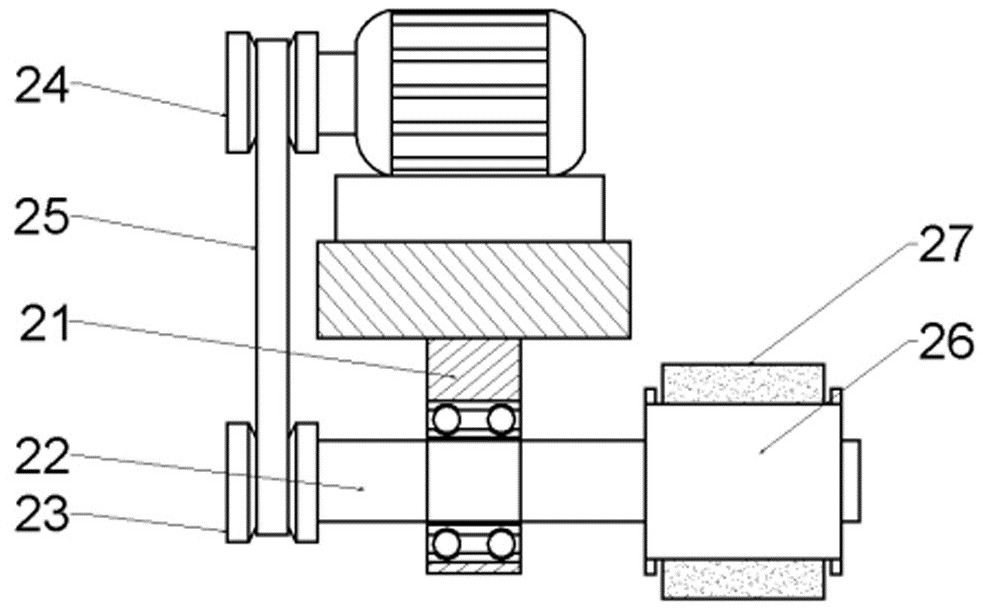

[0029] Embodiment 1: see Figure 1-6 , an intelligent carbon skateboard outer arc grinding device that is easy to adjust, including a base 1, the base 1 is a rectangular plate-shaped horizontally arranged, and a vertically arranged support column 2 is fixedly installed in the middle of one side of the top surface of the base 1, A rectangular rod-shaped crossbeam 3 is horizontally arranged on the top of the support column 3, and one end of the crossbeam 3 is fixedly connected to the top of the support column 2; The T-shaped guide rail 4 that is installed and arranged horizontally is fixedly connected with a rectangular stopper at one end of the T-shaped guide rail 4 away from the support column 2; A slider 5, on the T-shaped guide rails 4 inside the two first sliders 5, the second slider 6 is slidingly clamped, and the middle parts of the bottom surfaces of the first slider 5 and the second slider 6 are matched The T-shaped guide rail 4 is provided with a T-shaped chute in the t...

Embodiment 2

[0035] Example 2: see Figure 7 , in this embodiment, the present invention also proposes a grinding method for an intelligent carbon skateboard outer arc grinding device that is easy to adjust, including the following steps:

[0036] Step 1, firstly connect the first motor 15, the cylinder 17 and the second motor 20 to the external power supply through wires respectively, the staff first places the inner buckle of the carbon skateboard on the top of the circular block 32, and passes the carbon skateboard itself The gravity of the lifting rod 30 is pressed down, and the connecting rod 33 is driven down by the decline of the lifting rod 30 and the circular block 32, and the inward retraction of the top of the clamping arm 31 is driven by the decline of the connecting rod 33, and the top of the clamping arm 31 is The folding of the clamping plate 35 is clamped on both sides of the inner buckle of the carbon slide plate;

[0037] Step 2, by turning the handle 19 to drive the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com