Simple rust removing device for steel wires

A simple and simple technology for steel wire, applied in the field of simple rust removal device for steel wire, can solve the problems of fast wear, difficult to meet the rust removal operation of steel wire, increase energy consumption, etc., achieve long replacement cycle, good rust removal effect, and simple improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

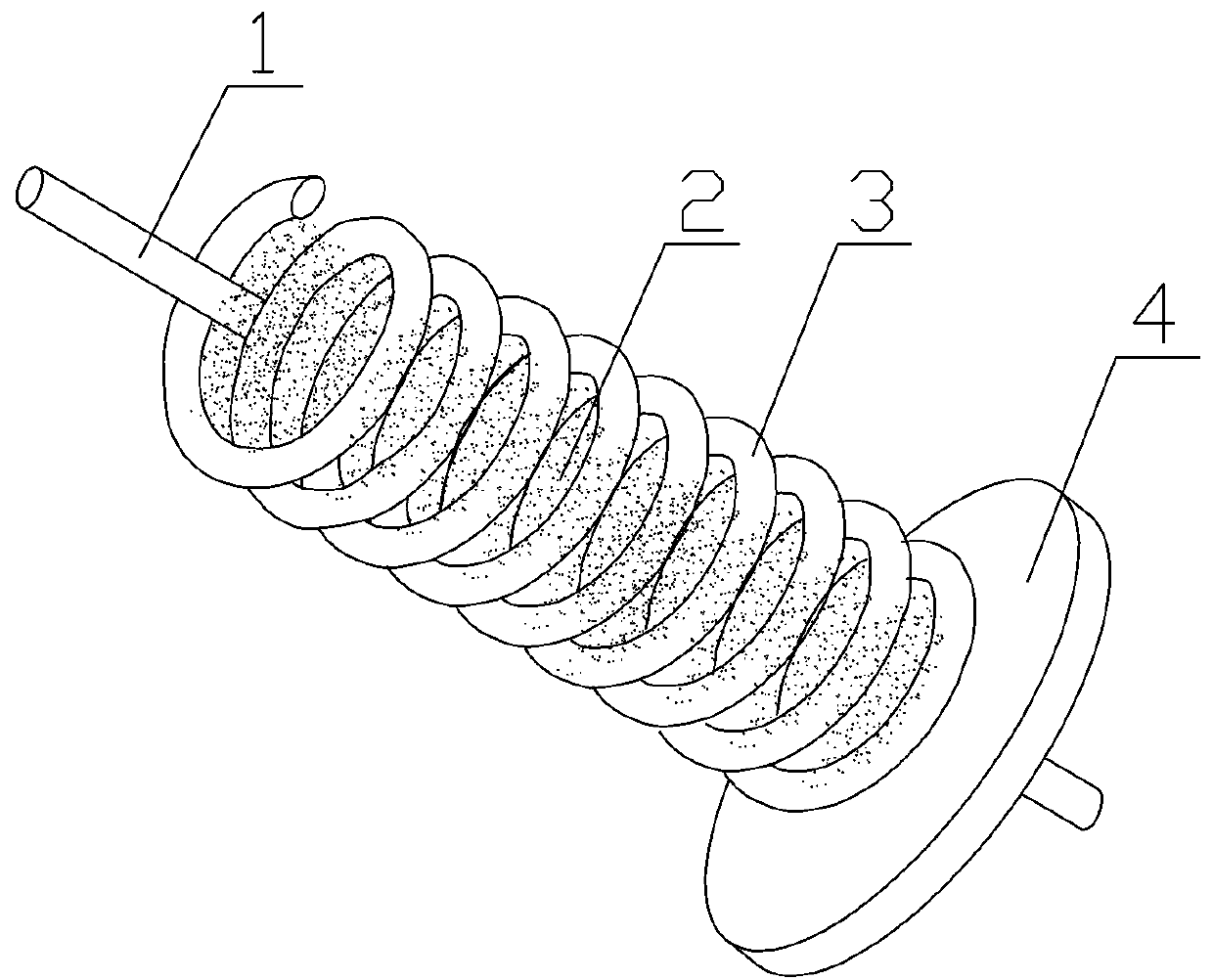

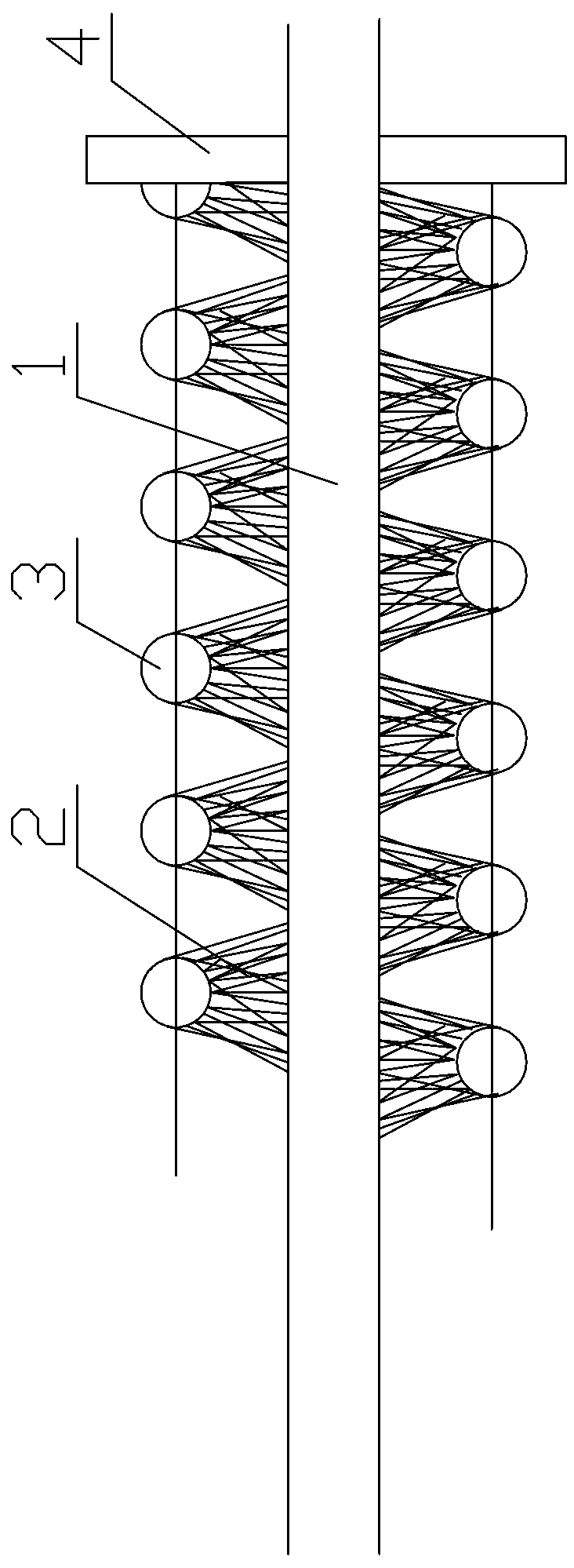

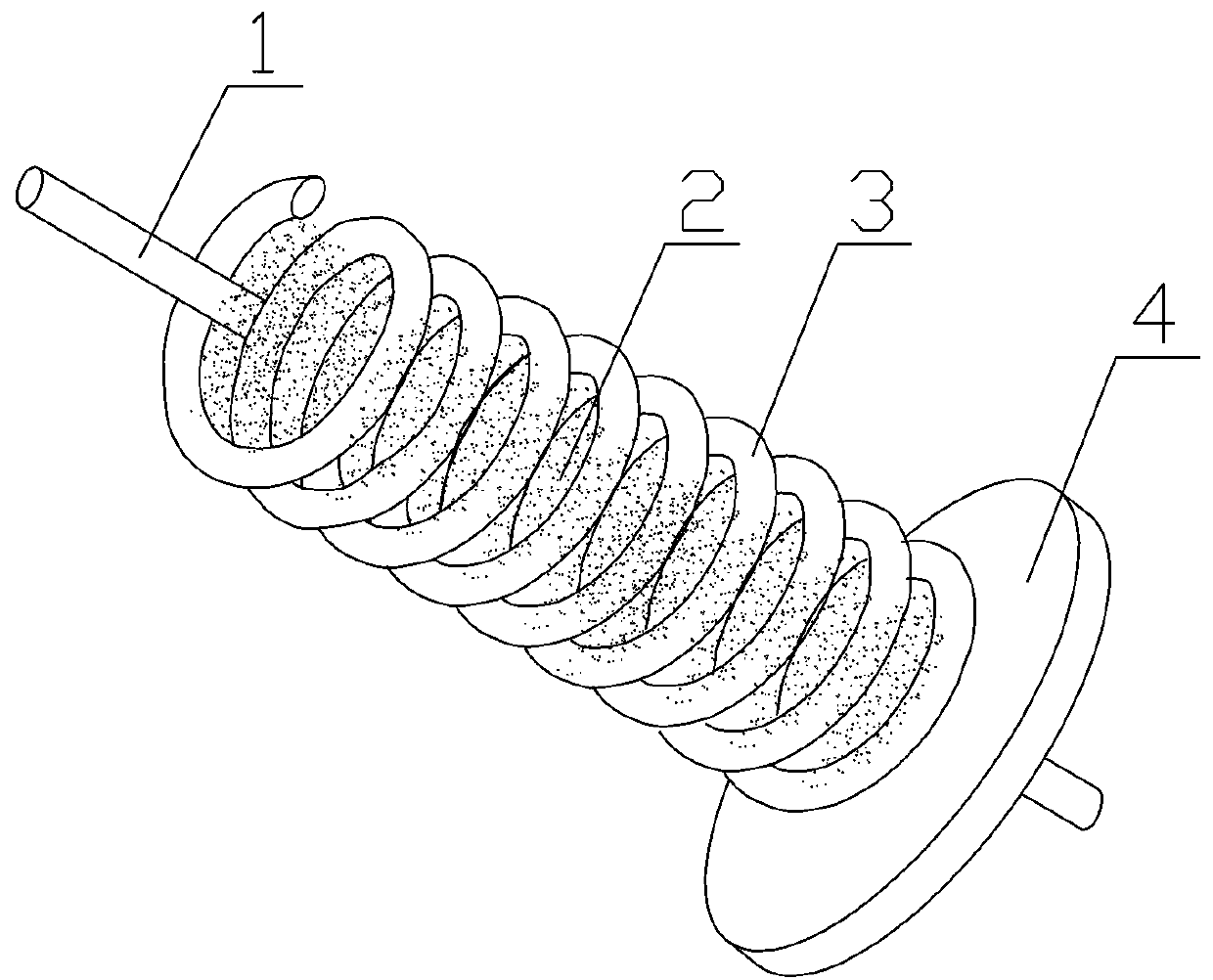

[0012] see figure 1 , figure 2 , the present invention is a simple rust removal device for steel wires, which has a spring body 3, and a wire brush 2 is arranged on the inner wall of the spring body along a spiral direction, and the wire brushes are distributed in a spiral shape.

[0013] Further, the spring body in this embodiment is a steel spring.

[0014] Further, in this embodiment, one end of the spring body is further provided with a baffle 4, and the baffle is fixedly connected with the spring body, and the center of the baffle is provided with a through hole for the steel wire 1 to pass through.

[0015] Further, the helical section of the spring body in this embodiment is any one of circular, rectangular and triangular.

[0016] The device of the present invention is mainly used in the derusting operation process on the surface of the steel wire, and is used to replace the traditional electric disc-type wire brush for derusting. Set wire brushes along the road, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com