Full-automatic robot hand-eye calibration method

A robot hand and calibration method technology, applied in manipulators, program-controlled manipulators, instruments, etc., can solve the problems of restricting the use of cameras and manipulators and manipulating space, affecting the accuracy of calibration results, time-consuming and laborious, and achieving easy deployment and use. , Calibration time saving, Time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

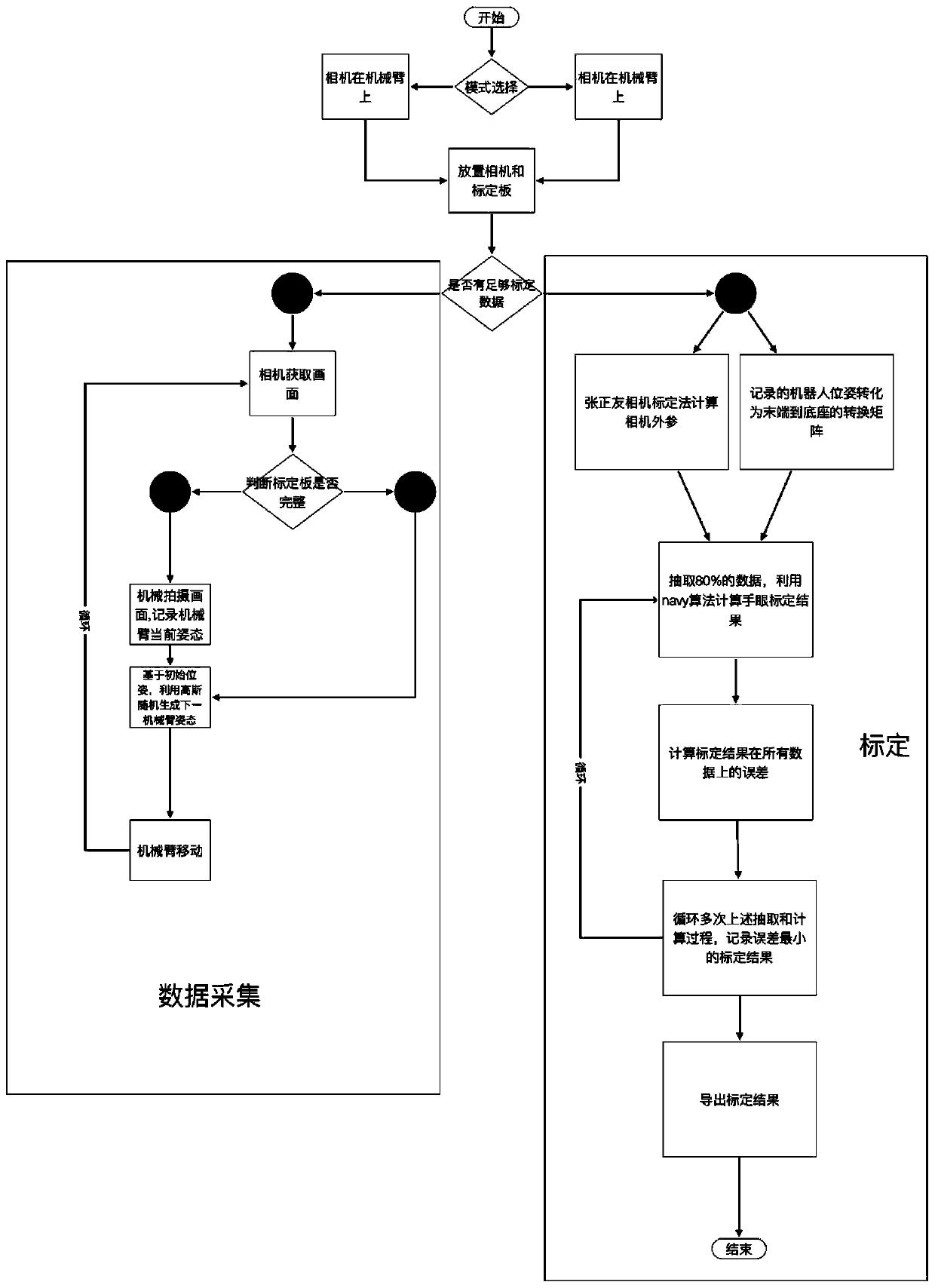

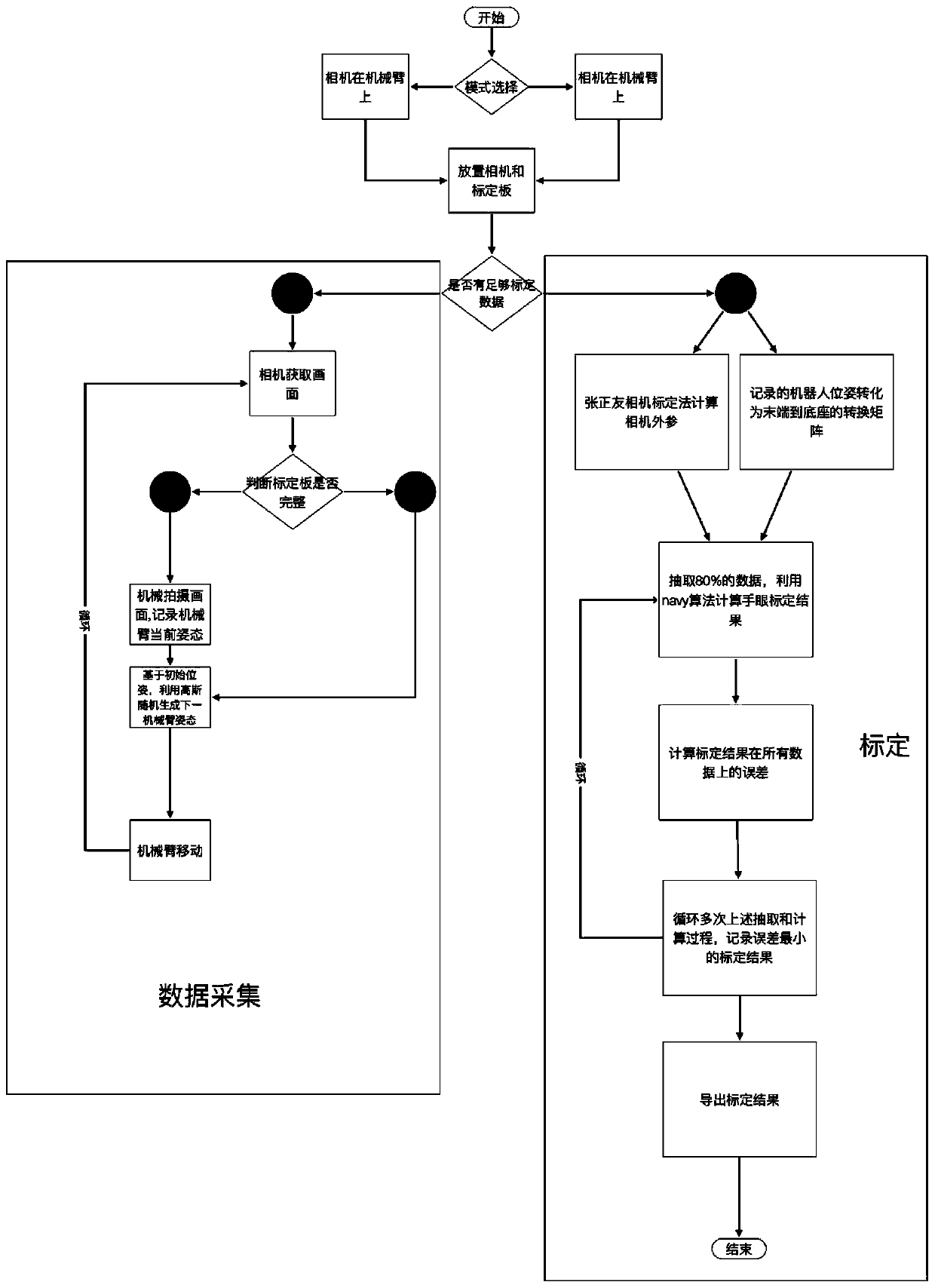

[0033] Such as figure 1 As shown, a fully automatic robot hand-eye calibration method, including the robot system, its specific steps are as follows:

[0034] S1: data acquisition;

[0035] S2: Mode selection: After the system is started, the required calibration mode can be selected, divided into two types: the camera is hung on the mechanical arm and the camera is fixed outside the mechanical arm;

[0036] S3: Manually install and place the calibration board:

[0037] a: When the camera is on the robot arm, the calibration board needs to be placed in the field of view of the robot;

[0038] b: When the camera is outside the robot arm mode, the calibration board needs to be installed at the end of the robot arm, and at the same time, ensure that the calibration board is within the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com