Waterless printing and dyeing production line based on uniform dyeing degree and smooth conveying

A production line and assembly line technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problems of large folds of fabrics, inaccurate printing of printing and dyeing patterns, light and uneven fabrics, etc., so that it is not easy to cross colors, save space, Deliver flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

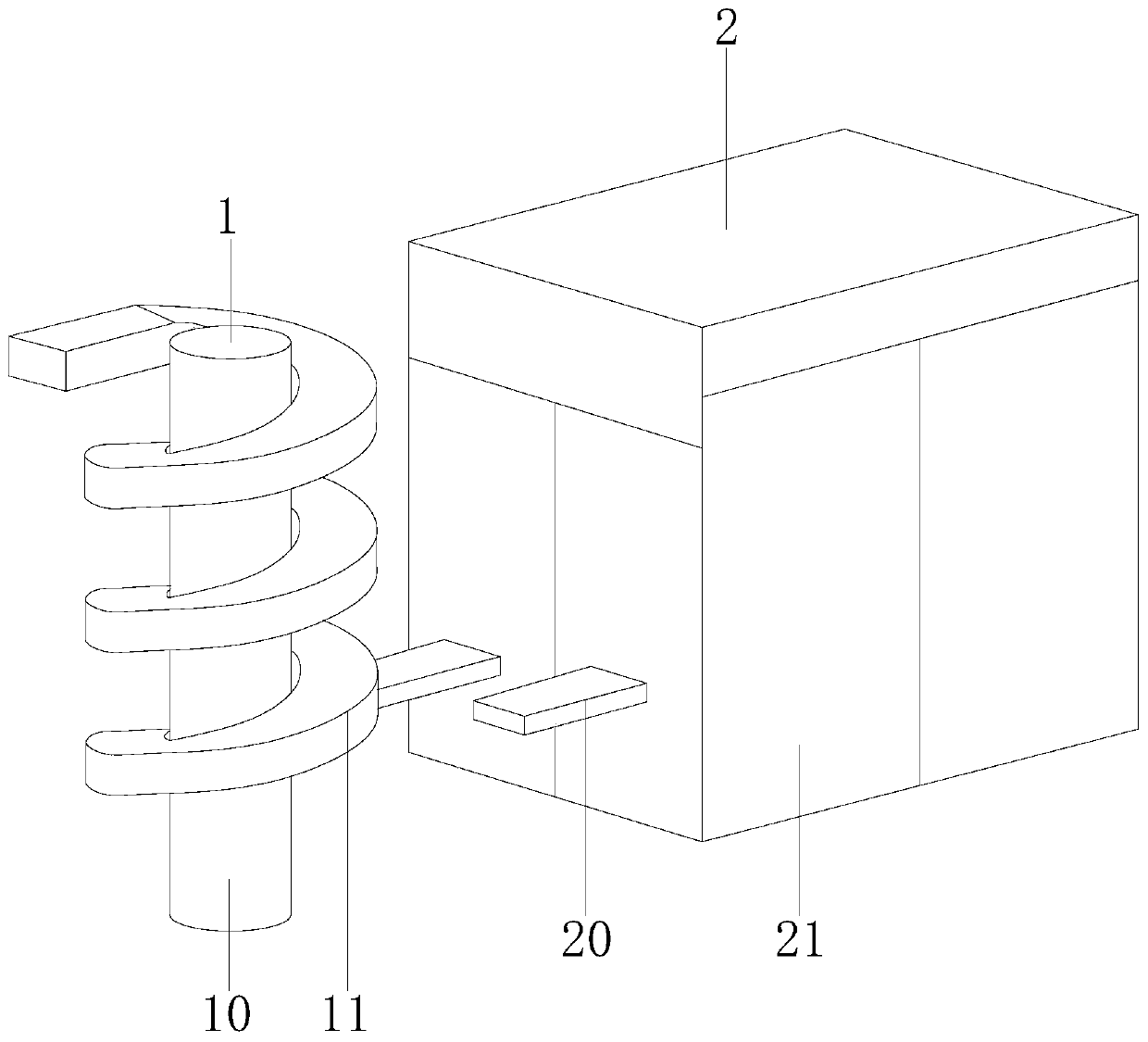

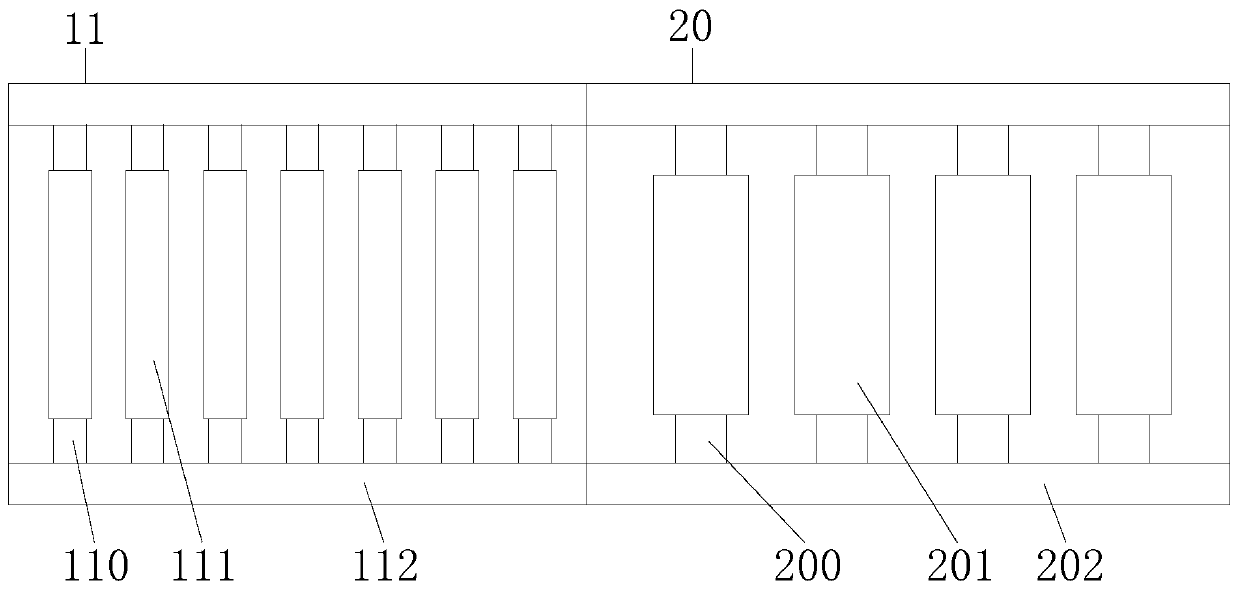

[0026] Example 1 see Figure 1-5 , the present invention provides a waterless printing and dyeing production line technical solution based on the uniform conveying and smooth dyeing degree: its structure includes a light fabric line 1 and a heavy fabric line 2, the light fabric line 1 and the heavy fabric line 2 are installed and connected, and the The fabric distribution line 1 is composed of a pillar 10 and a light material helix 11, and the pillar 10 is locked with the light material helix 11. The heavy material distribution line 2 is composed of a heavy material helix 20 and a dustproof cover box 21. The light material The helix 11 and the heavy material helix 20 respectively have a helical structure, and the screw conveying can effectively save space. Sealed isolation printing and dyeing is not easy to cross colors. The light material helix 11 is composed of a light material installation roller shaft 110, a light material roller rod 111, and a light material rack 112. The...

Embodiment 2

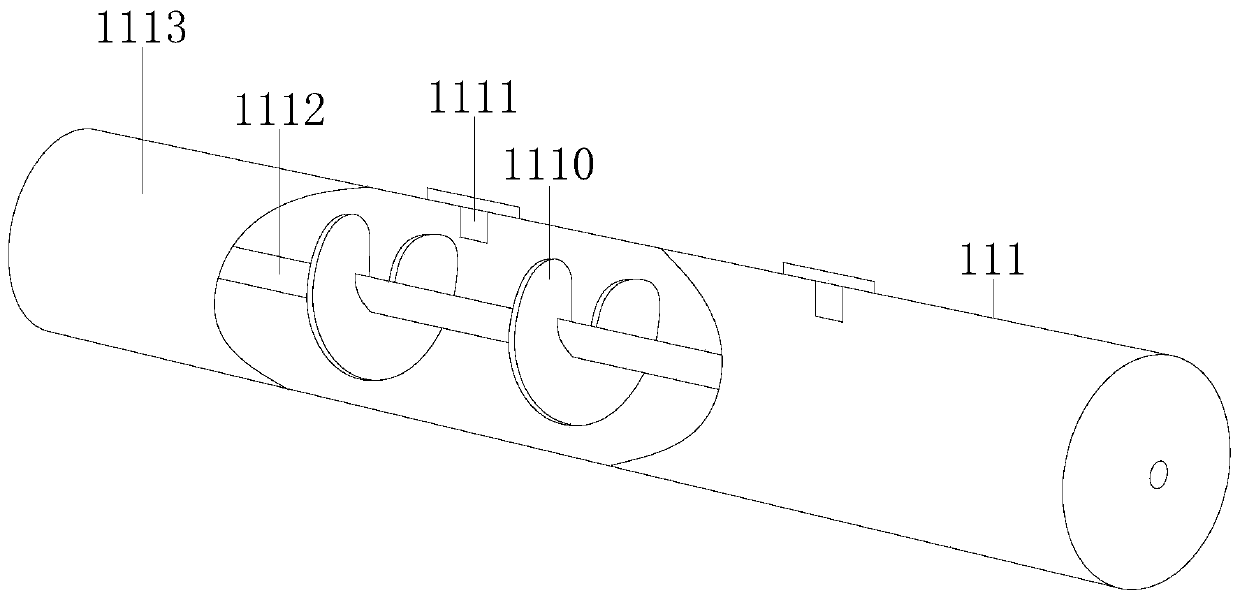

[0028] Example 2 see Figure 6-9 , the present invention provides a waterless printing and dyeing production line technical solution based on uniform conveying and smooth dyeing degree: the structure of the light material installation roller shaft 110 is the same as that of the heavy material installation roller shaft 200, and the light material installation roller shaft 110 starts from To the function of connecting and installing the light material roller rod 111 and the light material rack 112, the light material installation roller shaft 110 includes an inserting square plate 1100, a liquid shaft 1101, a roller adjuster 1102, a looser roller 1103, and an inserting circular plate 1104, the liquid shaft 1101 is used to open or close the printing and dyeing liquid material, the inserting square plate 1100 is installed and connected with the liquid shaft 1101, and the roller adjusting device 1102 is connected with the liquid shaft 1101 and the roller loosening device 1103 The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com