Chip stack liquid cooling heat exchanger

A technology of liquid-cooled heat exchangers and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, electric solid devices, etc., can solve the problem of easy concentration of stress at the interface of liquid-cooled cold plates and the thermal control resources of cold plates The utilization rate is not high, the chip temperature is difficult to control independently, and the manufacturing process is simple and reliable, the structure is compact, and the effect of easy processing is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

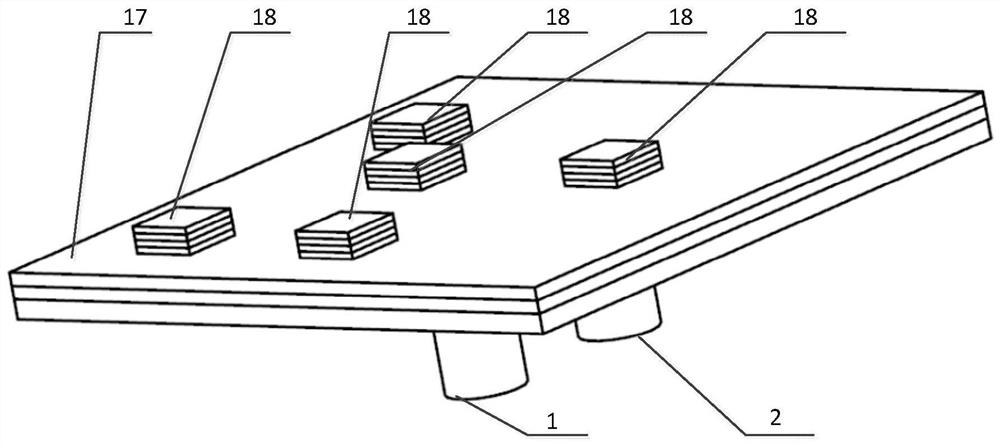

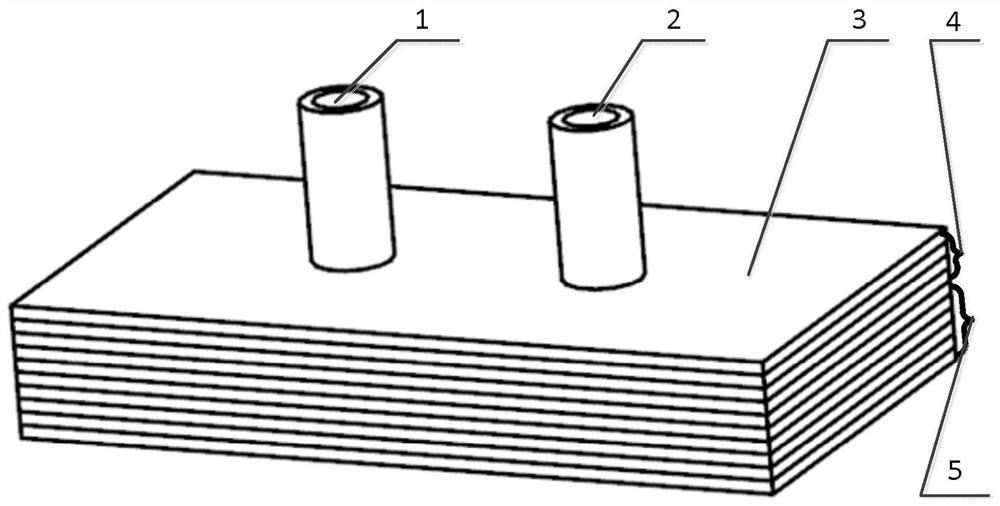

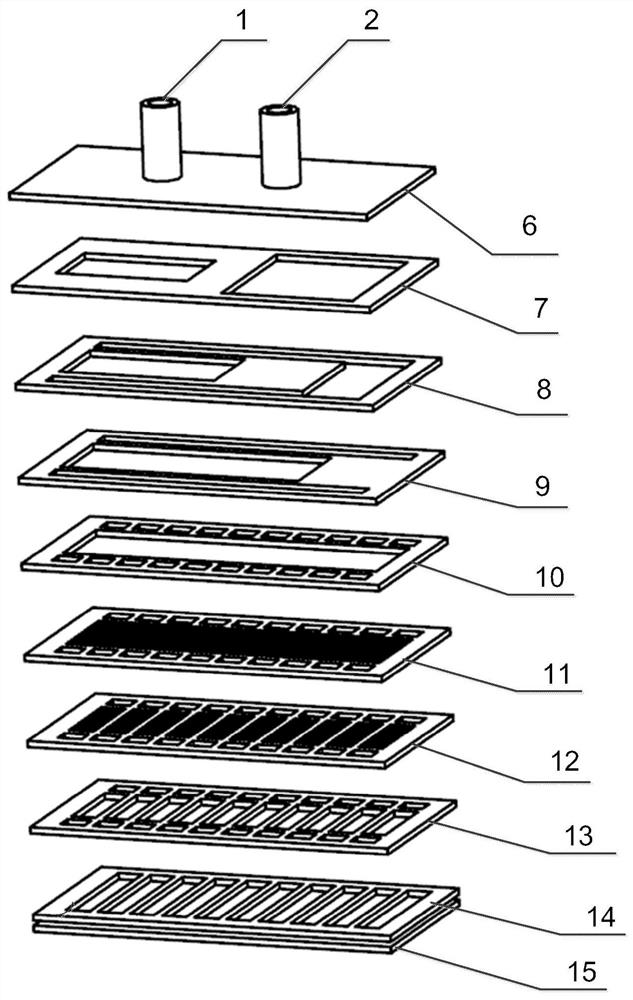

[0023] refer to Figure 1-Figure 3 . In the preferred embodiment described below, a sheet-type stacked liquid-cooled heat exchanger includes: stacked liquid-cooled plate heat exchangers 18 distributed on a liquid-cooled substrate 17 . On the stacked liquid-cooled plate heat exchanger 18, a cooling medium inlet pipe 1 and a cooling medium outlet pipe 2 are formed, including a plate-level stacked rectangular sheet-type liquid-cooled collection layer 4 and subdivided flow channels for heat exchange. Layer 5 is stacked and laminated cold plates 3, and the liquid-cooled collection layer 4 is made of at least four layers that collect subdivided channels along the dislocation distribution of round holes, rectangular strip holes, and square hole structures, and top sealing connecting pieces 6, the first collection Sheet 7, the second collection sheet 8 and the third collection sheet 9; the heat exchange layer 5 is located below the liquid-cooled collection layer 4, based on the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com